Plastics Shrinkage Rate & Mold Shrinkage Rate

Plastics Shrinkage Rate & Mold Shrinkage Rate

It is very important for each product design to know the plastics shrinkage rate. So that when he designs his parts design, he can present the right scale size of the drawing to mold manufacturing factory like Intertech.

Intertech provides here with the referenced of the most common used plastics shrinkage rate chart to help the product designer to double check their product design. Intertech will provide our experience for helping customer to select the right plastics for their project. Welcome to discuss with Intertech for any

Plastics material shrinkage rate application

Mold Shrinkage Rate

Meanwhile, the mold shrinkage rate corresponses the material shrinkage rate and provides good information for production injection molding factory for calculating the final finished product size to be formed in final shape.

Intertech’s mold design and engineering team is quite profession in helping customer to double check this correspondence and build the best mold, product the best finished for customer. Welcome to discuss us with your project.

| Plastics Shrinkage Rate | ||

| General Plastics | Shrinkage Rate (%) | |

| Raw Material | Add. 30% GF | |

| LDPE | 2.0 | 0.5 |

| HDPE | 2.0 | 0.4 |

| PP | 1.8 | 0.4 |

| PS | 0.6 | 0.1 |

| PVC | 0.4 | 0.1 |

| PMMA | 0.5 | 0.1 |

| ABS | 0.6 | 0.1 |

| Engineering Plastics | Shrinkage Rate (%) | |

| Raw Material | Add. 30% GF | |

| NY6 | 1.5 | 0.4 |

| NY66 | 1.5 | 0.4 |

| PBT | 2.0 | 0.4 |

| POM | 2.5 | 0.5 |

| PC | 0.6 | 0.1 |

| PPO | 0.6 | 0.1 |

| Mold Shrinkage Rate | ||

| Plastics | Glass Fiber Adding | Mold Shrinkage Rate |

| [%] | [%] | |

| PS | 0.3-0.6 | |

| HI-PS | 0.5-0.6 | |

| SAN | 0.5-0.7 | |

| ABS | 0.4-0.7 | |

| ASA | 0.4-0.6 | |

| LDPE | 1.5-5.0 | |

| HDPE | 1.5-3.0 | |

| PP | 1.0-2.5 | |

| PP+GF | 30 | 0.5-1.2 |

| PVC-soft | >0.5 | |

| PVC-rigid | 0.5 | |

| PVDF | 3.0-6.0 | |

| PMMA | 0.1-0.8 | |

| POM | 1.9-2.3 | |

| PPO | 0.5-0.7 | |

| PPO+GF | 30 | <0.7 |

| CA | 0.5 | |

| PC | 0.8 | |

| PC+GF | 10~30 | 0.15-0.55 |

| PBT | 1.5-2.5 | |

| PBT+GF | 30-50 | 0.3-1.2 |

| PA6 | 0.5-2.2 | |

| PA6+GF | 30~50 | 0.3-1 |

| PA66 | 0.5-2.2 | |

| PA66+GF | 30~50 | 0.5-1.5 |

| PA11 | 0.5-1.5 | |

| PA12 | 0.5-1.5 | |

| PPS | 40 | 0.2 |

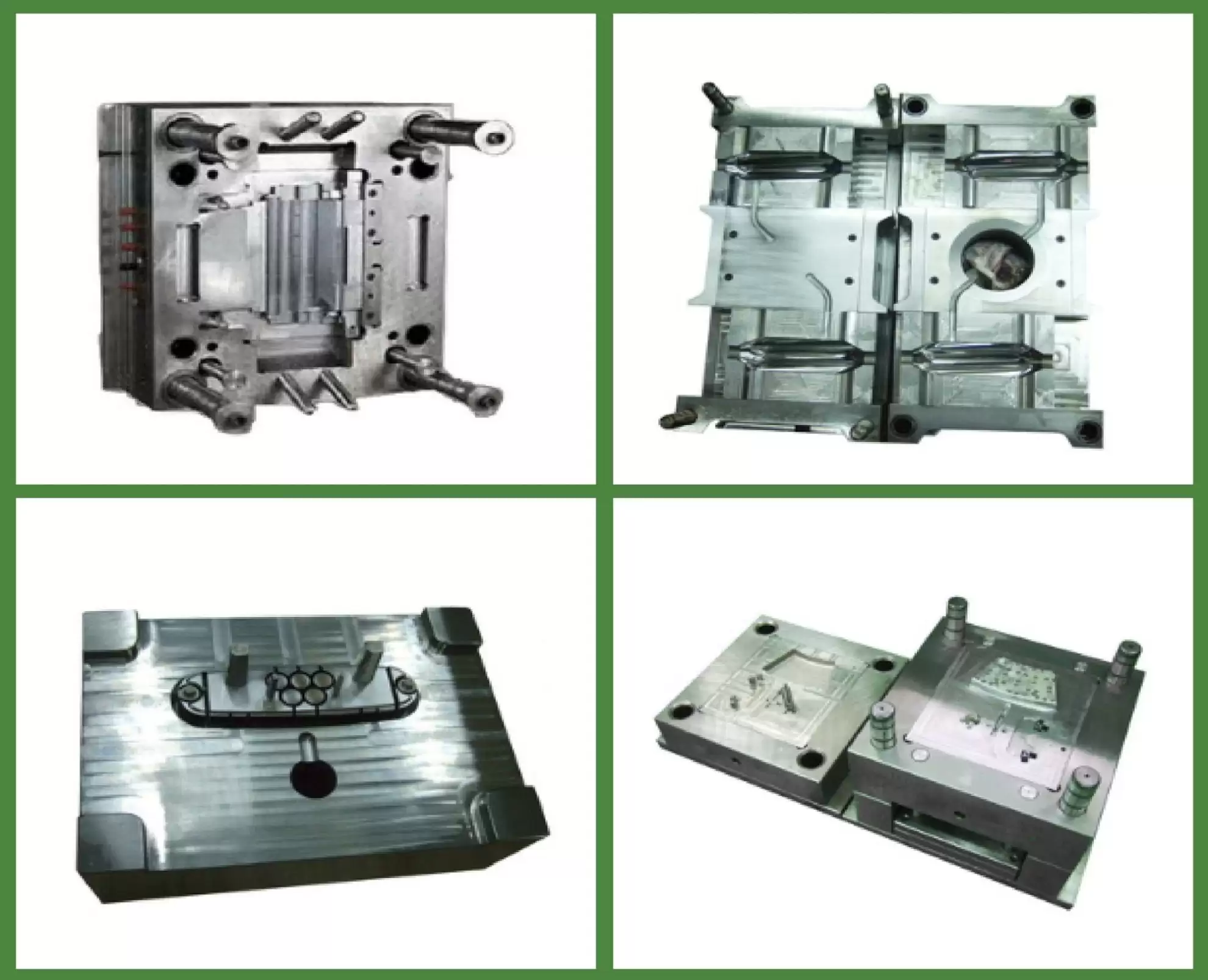

Taiwan factory manufacturing for all the plastic injection mold requirements, communications, Auto mold, Household mold, Electrical mold, LED mold, Medical mold, lens mold, etc.

SEND INQUIRY NOW !

German and Japan Imports Mold Steel

High Mold Quality and Precision

Intertech can provide you customized, high-qulaity mold and molding service and new product information from our factory, Taiwan. Do you have any suitable plastic, silicone, metal item mold and molding project for us now? You will be satisfied with

our price report! Expecting your reply !

As a plastic molding manufacturing , we are the factory with plastic moulding capability of 50-250T machines in house output and 300-3000T machines output in associated party.

Mold and Molding Service

Frequently bought together

Looking for a Reliable Plastic Injection Partner with Engineering Support?

For over 30 years, INTERTECH has helped global brands and manufacturers turn ideas into high-quality plastic components with precision mold design, fast prototyping, and scalable injection molding. But we don’t just make parts — we offer full-cycle support to help you build better products.

✅ Engineering Consultation – Get expert guidance on optimizing part design, tooling, and mold flow

✅ Component Sourcing Advice – Select the right plastic materials, manufacturing methods, and suppliers across Asia

✅ Product Development Support – From concept to production, we help bring your plastic products to market with confidence

Based in Taiwan, INTERTECH combines technical expertise with cost-effective manufacturing — trusted by clients in automotive, medical, electronics, and consumer goods industries.

Contact INTERTECH today to discuss your next project — and discover the value of a manufacturing partner who truly understands your needs.