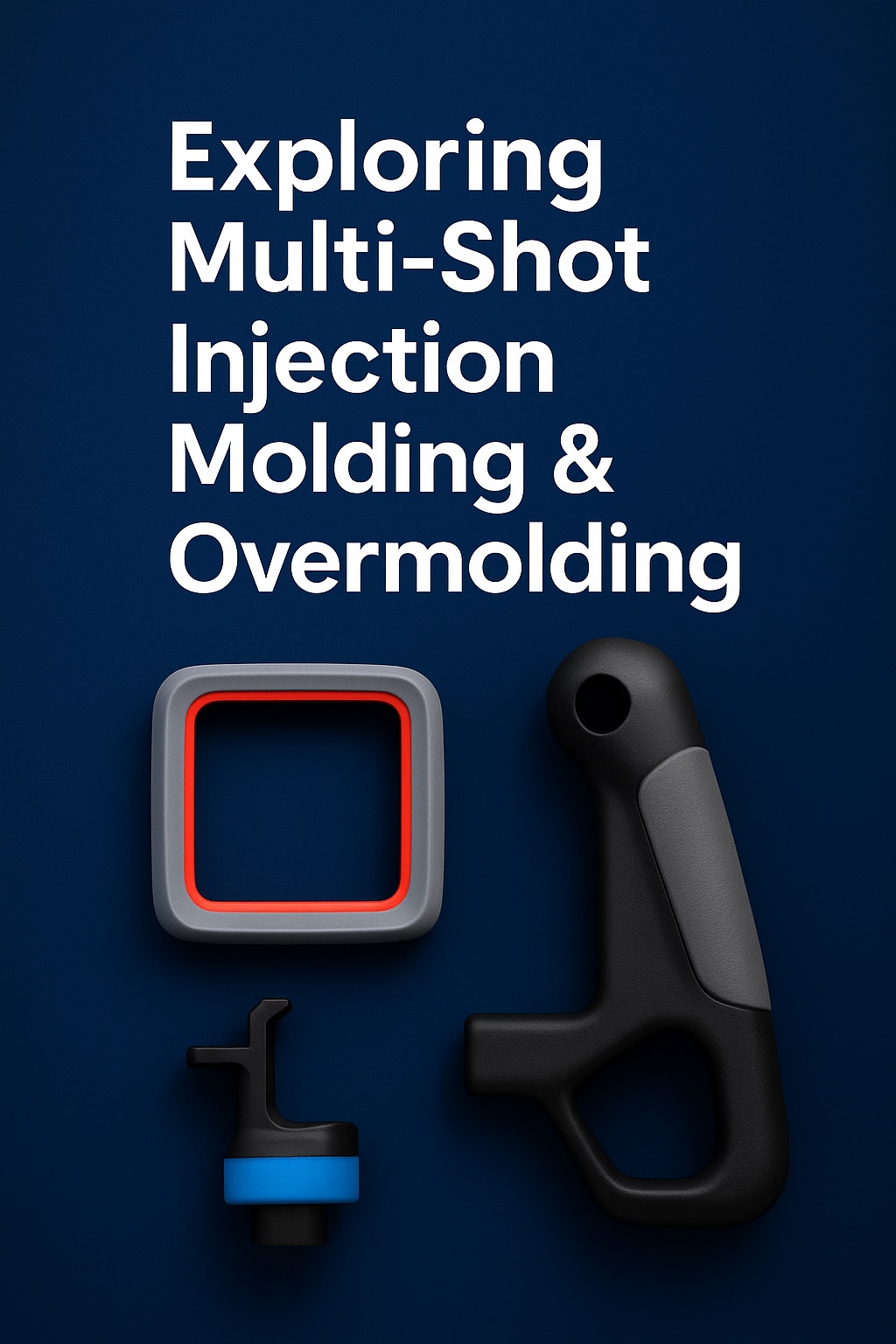

Exploring Multi-Shot Injection Molding and Overmolding for Advanced Product Design

Exploring Multi-Shot Injection Molding and Overmolding for Advanced Product Design

1 Introduction

Modern consumers expect products that look great, feel premium, and combine multiple functions in one compact form factor. Engineers, meanwhile, face unrelenting pressure to slash part counts, shorten assembly windows, and meet stricter regulatory targets.

Enter multi-shot injection molding and overmolding—advanced tooling strategies that bond two or more materials into a single, inseparable component right inside the mold. From soft-touch wearable enclosures to high-gloss automotive switch bezels, these processes let designers add color, texture, sealing, and even electronics without a secondary assembly step.

2 What Are Multi-Shot and Overmolding Processes?

| Term | Core Idea | Typical Machine / Tooling Setup | When to Use |

|---|---|---|---|

| 2K / Two-Shot Molding | Two materials injected sequentially in the same clamp cycle; the substrate rotates or slides to the second shot. | Rotary-table or index-plate mold, two barrels. | High volume, tight tolerance aesthetic parts (e.g., toothbrush handles, phone buttons). |

| Multi-Shot Injection Molding | Three or more resins/colors processed in a single mold cycle. | Multi-barrel press; triple-shot rotary stack. | Complex branding colorways, integrated seals + windows + structural skeletons. |

| Overmolding | A pre-molded substrate (plastic, metal, PCB) is re-inserted into a second mold for a soft or rigid overcoat. | Two separate tools or family mold; could be same or different press. | Moderate volumes, insert-molding electronics, soft-grip surfaces, EMI shielding. |

All three fall under the broader umbrella of multi-material molding, delivering a spectrum of cost, complexity, and performance benefits.

3 How 2K / Two-Shot Molding Works

-

First Shot – Substrate Creation

-

Resin A (usually rigid) fills cavity set #1, establishing the structural framework.

-

-

Index / Rotate

-

The core side rotates 180 ° (or slides) so the freshly molded substrate aligns with cavity set #2.

-

-

Second Shot – Overcoat or Accent

-

Resin B (often elastomeric or contrasting color) injects over the designated regions.

-

-

Cooling & Ejection

-

Both materials solidify simultaneously; the part ejects as a finished, fully bonded unit.

-

Because the two materials fuse while still molten, chemical and mechanical adhesion exceeds that of post-mold assembly, ensuring leak-free seals and tamper-proof aesthetics.

4 Key Advantages

| Advantage | Why It Matters |

|---|---|

| Part Consolidation | Replace two to six separate SKUs with one molded assembly—cuts BOM cost, inventory, and QA steps. |

| Enhanced Aesthetics | Seamless color breaks, clear light pipes, metallic logos, or piano-black buttons without paint. |

| Integrated Sealing & Dampening | Directly mold TPV/TPU gaskets onto rigid housings—IP67 performance with zero O-rings. |

| Improved Ergonomics | Soft-touch grips and over-molded bumpers absorb shock and reduce fatigue in hand tools and medical devices. |

| Tighter Tolerances | Single-clamp cycle means zero accumulation of stack-ups from secondary gluing or screwing. |

| Sustainability Gains | Fewer assembly fixtures, reduced scrap, and lower shipping masses cut the carbon footprint of the entire supply chain. |

5 Typical Products & Part Families

-

Consumer Electronics – earbuds, smartwatch bezels, phone keycaps, protective cases

-

Automotive Interiors – HVAC control knobs, illuminated ID bezels, soft-feel dash inserts

-

Medical Devices – insulin-pen bodies, catheter hubs, point-of-care test housings

-

Industrial IoT Sensors – IP67 enclosures with integrated lens windows and potting dams

-

Sporting Goods – multi-durometer shoe soles, bike grips, goggle frames

-

Home Appliances – mixer handles, dishwasher racks with thermoplastic-rubber feet

6 Industry-Specific Applications

6.1 Automotive (Interior & Exterior)

-

Challenge: Deliver premium tactile interfaces while passing cycle testing, UV, and chemical resistance.

-

Solution: Two-shot PC/ABS + TPU rotary tools with in-mold backlighting windows reduce touch-point squeak and eliminate paint.

6.2 Medical & Life Sciences

-

Challenge: Bond clear PC with silicone seals in ISO 13485 environments.

-

Solution: Overmold platinum-cured LSR onto gamma-stable PC barrels; maintains biocompatibility and leak integrity after sterilization.

6.3 Consumer Electronics

-

Challenge: Achieve bezel-less, scratch-resistant lenses and ultra-thin gaskets.

-

Solution: Multi-shot Light-Guide Resin (LGR) + high-flow PC blend yields slim wearable modules ready for ultrasonic over-seal welding.

6.4 Power Tools & Outdoor Equipment

-

Challenge: Combine structural ribs with vibration-dampening grips.

-

Solution: GF-Nylon substrate with Shore A 60 TPV overmold passes 1 m drop test and 2,000-hour sun exposure.

6.5 Industrial & IoT Hardware

-

Challenge: Reduce enclosure assembly steps under tight lead times.

-

Solution: Two-shot PBT + silicone gasket frame achieves IP68 rating in a single clamp cycle, slashing labor by 40 %.

7 Design & Material Best Practices

-

Adhesion Pairing

-

Consult manufacturer compatibility charts (e.g., PC + TPU, ABS + TPE). Run peel-test coupons early.

-

-

Wall-Thickness Harmony

-

Second-shot walls should be 0.6 × – 1.0 × first-shot thickness to minimize sink and differential cooling stress.

-

-

Shut-Off Geometry

-

Use 3 °–5 ° shut-off draft angles to ensure steel-on-steel seal between shots; avoid knife-edge overlaps.

-

-

Gate Placement

-

Gate the overmold on the thickest section and design flow to wrap toward thin ribs; reduces knit lines on Class-A faces.

-

-

Tooling Economics

-

Rotary two-shot adds 15 %–30 % to mold cost but often recovers within 50 k–100 k cycles thanks to assembly savings.

-

-

Simulation & DOE

-

Run multi-material Moldflow and a fractional factorial DOE during T-1 to lock in a CpK ≥ 1.67 window.

-

8 Case Snapshot – Automotive HMI Bezel

| Metric | Conventional Single-Shot + Paint | Two-Shot PC + PMMA |

|---|---|---|

| Cosmetic Scrap Rate | 12 % (dust nibs, drips) | 2 % |

| Assembly Labor | 2.5 minutes per part | 0.5 minutes |

| Cost / Part (50 k pcs) | $3.42 | $2.76 |

| Lead Time to SOP | 16 weeks | 10 weeks |

By embedding the piano-black surface and clear indicator window in one two-shot cycle, the OEM met tough launch dates while saving $33 k in total project cost.

9 Start Your Project with TaiwanMoldMaker.com

Ready to turn multi-material concepts into reality? TaiwanMoldMaker.com connects you with ISO 9001, IATF 16949, and ISO 13485 certified partners equipped with rotary 2K presses from 60 t to 450 t.

-

48-Hour Multi-Shot DFM Pack – gating, shut-off, and adhesion road-map

-

Prototype-to-Production Credits – aluminum 2K bridge tools rolled into H13 steel cavities

-

Live MES Dashboards – monitor CpK, OEE, and OTIF in real time

Explore Our Key Services at Taiwan Mold Maker:

✔️ Custom Mold and Design Maker — Tailored mold design and engineering support for unique product requirements.

✔️ Mold Service — Full-process mold development from DFM to tooling and validation.

✔️ Injection Mold — High-precision plastic injection molds for mass production.

✔️ Silicone Mold — Flexible, heat-resistant silicone molds for consumer and industrial use.

✔️ Liquid Silicone Rubber Mold — Ideal for healthcare, baby products, and precision soft-touch applications.

✔️ Metal Stamping — Integrated sheet metal solutions for hybrid plastic-metal components.

✔️ Molding — Reliable molding services for short-run or mass production of plastic parts.

✔️ Customer Examples — Real case studies from global clients in automotive, electronics, medical, and more.

Upload your CAD today and receive a no-obligation quote plus process simulation within two business days—so your next product can launch faster, look better, and last longer.