Mold steel difference of H13, NAK80, 718 & P20

Mold steel difference of H13, NAK80, 718 & P20

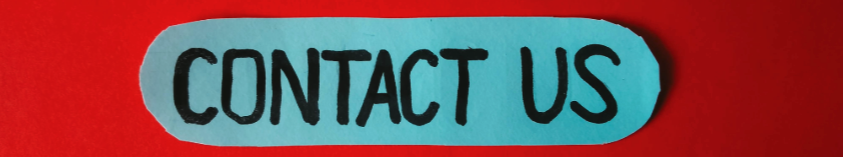

Mold steel quality decides the mold performance and the mold life time , so, it is very important to select the correct mold steel for your project application. Intertech will help you to select the suitable mold steel with our thirty years experience and knowledge.Furthermore, the origin of the mold steel made decides the quality of the steel,

all our mold steels are imported from German and Japan with formal quality certificate which 100% ensures your mold steel performance and life time.

For H13,

This is a harden steel, requires to make the heat treatment, normally the hardness is with 48-52HRC. Mold life can be up to 800000~1 million shots.

For NAK80,

This is a pre-harden steel, hardness is with 37-40HRC, mold life can be up to 400000~500000 shots

For 718,

This is a pre-harden steel, hardness is with 30-33HRC, mold life can be up to 300000~400000 shots

For P20,

This is a pre-harden steel, hardness is with 28-32HRC, mold life can be up to 200000~300000 shots

From above steels, H13 is the best steel, after that, it is NAK80, 718, P20.

In addition, many customers likes to use Starvax 420 steel, this normally can

ensure the cycle time more than one million shots.

For the price level, above steel grade are in difference level, Starvax 420 is

The most expensive one, H13 is the second expensive one, after that, it is

NAK80, 718 & P20.

Hightlight :

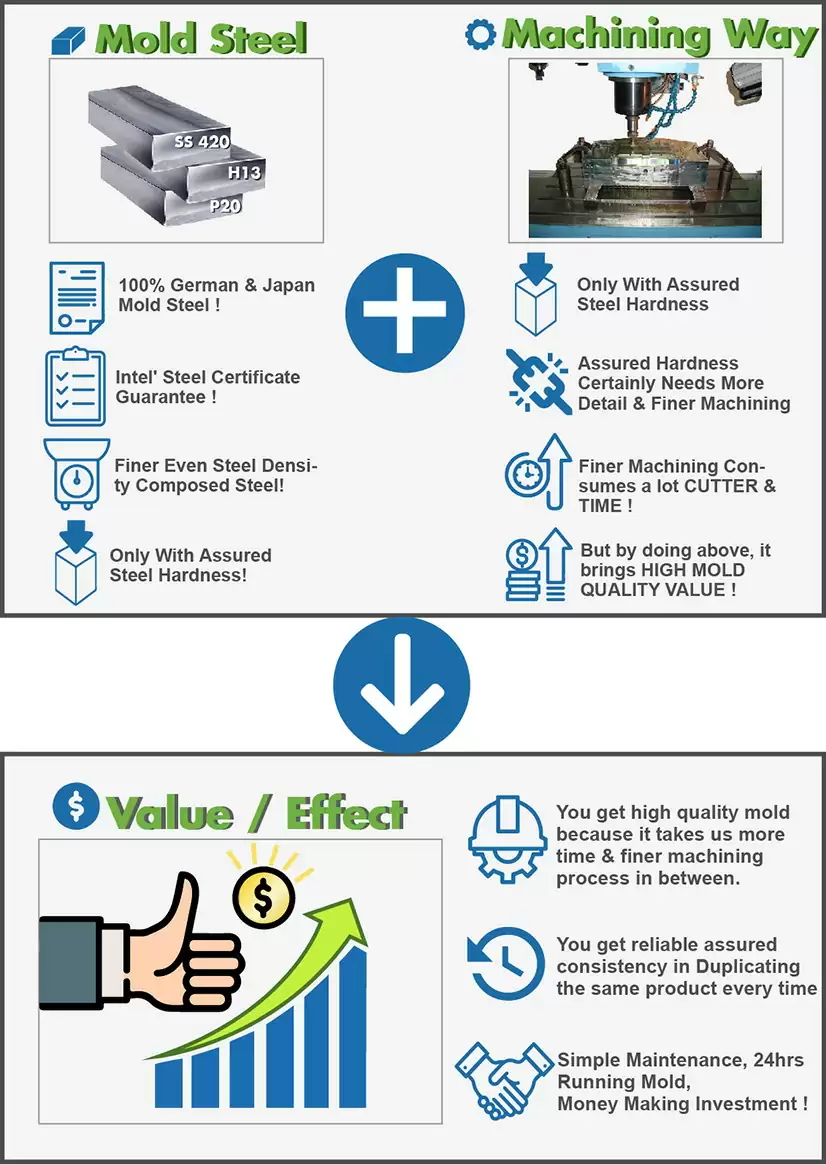

Good quality (steady, averaged even in every section of the entire steel) requires certain machining process hours to ensure the quality level. Comparing with those lousy low quality and cheap price steels, all Intertech’s imports German and Japan mold steels will take longer time in machining house (because its steady, averaged even in every section of the steel) and consumed more cutters during the machining process, but this will bring you a fruitful outcome for good steel performance, quality and lifetime value.

Looking for a Reliable Plastic Injection Partner with Engineering Support?

For over 30 years, INTERTECH has helped global brands and manufacturers turn ideas into high-quality plastic components with precision mold design, fast prototyping, and scalable injection molding. But we don’t just make parts — we offer full-cycle support to help you build better products.

✅ Engineering Consultation – Get expert guidance on optimizing part design, tooling, and mold flow

✅ Component Sourcing Advice – Select the right plastic materials, manufacturing methods, and suppliers across Asia

✅ Product Development Support – From concept to production, we help bring your plastic products to market with confidence

Based in Taiwan, INTERTECH combines technical expertise with cost-effective manufacturing — trusted by clients in automotive, medical, electronics, and consumer goods industries.

Contact INTERTECH today to discuss your next project — and discover the value of a manufacturing partner who truly understands your needs.