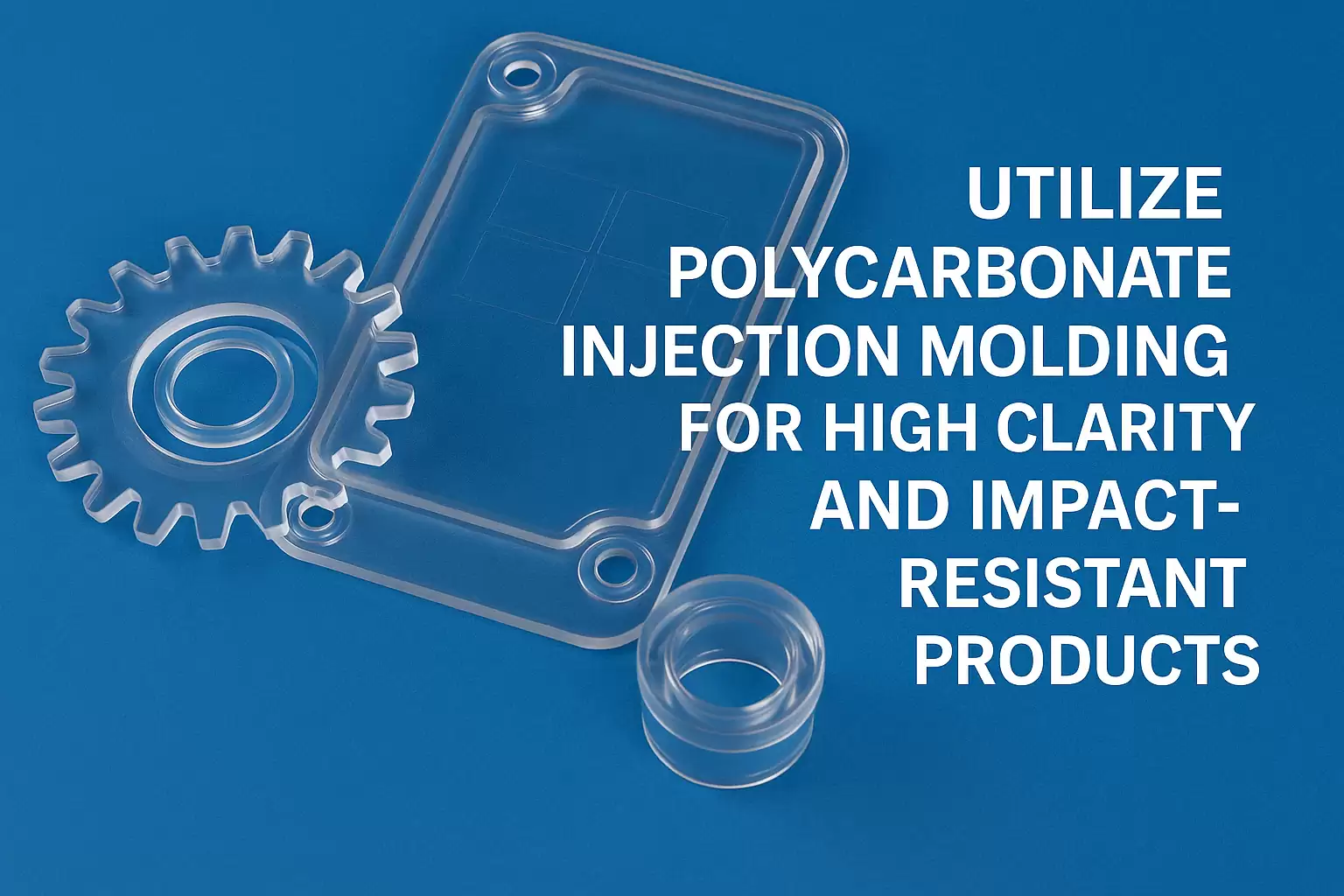

Utilize Polycarbonate Injection Molding for High Clarity and Impact-Resistant Products

Utilize Polycarbonate Injection Molding for High Clarity and Impact-Resistant Products

When product strength and visual clarity matter most, polycarbonate injection molding stands out as the material solution of choice. Known for its optical transparency and extreme toughness, polycarbonate (PC) is used across industries that demand safety, aesthetics, and durability. At INTERTECH (https://www.taiwanmoldmaker.com), we help businesses take full advantage of polycarbonate’s benefits through precision mold design, material expertise, and cost-efficient manufacturing.

What Is Polycarbonate and Why Choose It?

Polycarbonate is a high-performance thermoplastic with a unique combination of properties:

-

High impact resistance – over 200 times stronger than glass

-

Exceptional clarity – up to 90% light transmission

-

Good dimensional stability – maintains form under heat and stress

-

Sterilization compatibility – suitable for medical or food-grade use

-

Flame resistance and electrical insulation – ideal for electronics and lighting

Because of these characteristics, PC is widely used in:

-

Medical device housings

-

Transparent safety shields and lenses

-

Consumer electronics

-

Automotive light covers and interiors

-

Industrial machine guards

Advantages of Polycarbonate Injection Molding

1. Clarity Without Compromise

Polycarbonate provides glass-like transparency while offering superior impact resistance. It is ideal for:

-

Light diffusers

-

Optical covers

-

Transparent medical enclosures

2. Durability in Demanding Environments

Polycarbonate parts remain tough in high-stress and high-temperature environments. This makes them ideal for:

-

Protective equipment

-

Outdoor housings

-

High-use mechanical parts

3. Easy Customization and Finishing

With polycarbonate, you can achieve:

-

Precision molding of complex geometries

-

Surface texturing, polishing, or coloring

-

Secondary processes such as ultrasonic welding or printing

Key Design Considerations for Polycarbonate Molding

To ensure optimal results, design and processing must account for:

-

Mold temperature control – critical for reducing stress and maintaining clarity

-

Gate location and flow balance – to avoid visual defects or warping

-

Ventilation – to prevent air traps and burning during injection

At INTERTECH, our engineering team offers DFM (Design for Manufacturability) analysis to optimize your PC part before tooling.

INTERTECH’s Polycarbonate Molding Expertise

INTERTECH provides full-service support for polycarbonate injection molding, including:

-

In-house tool design and mold manufacturing

-

Mold flow simulation and material flow analysis

-

Low and high volume production runs

-

Experience with optical-grade and flame-retardant PC resins

-

Support for tight tolerance and transparent part applications

View our custom molding services or contact us for a technical consultation.

Applications Across Industries

Medical:

-

Transparent housings, diagnostic covers, surgical instrument handles

Automotive:

-

Interior trim, light covers, electronic modules

Electronics:

-

LED lenses, connectors, switch panels, protective casings

Industrial:

-

Machine guards, safety panels, inspection windows

Conclusion

Polycarbonate injection molding offers a rare combination of clarity, impact strength, and design versatility. By partnering with a specialized manufacturer like INTERTECH, you can achieve flawless, cost-effective PC parts suited for demanding markets.

Looking for a trusted polycarbonate molding expert? Contact INTERTECH today to start your project.