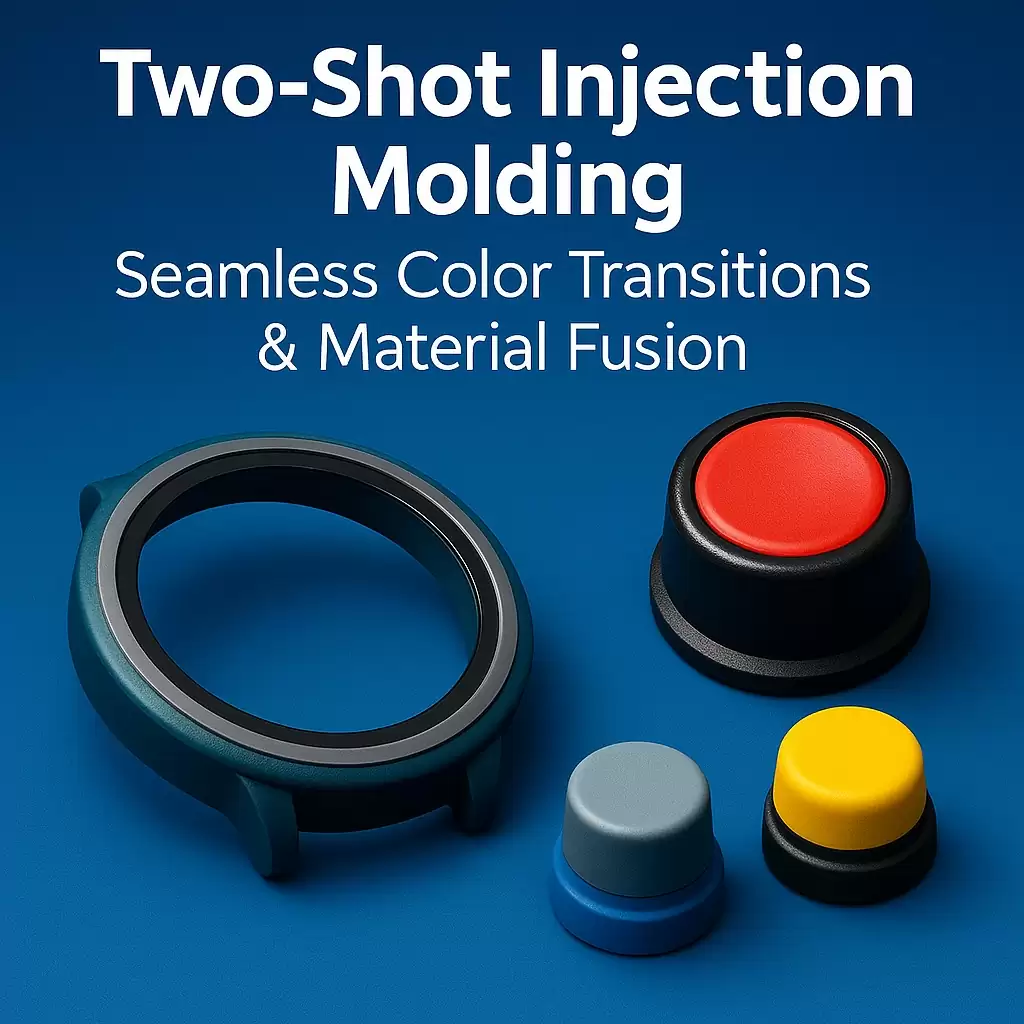

Apply Two-Shot Injection Molding for Seamless Color Transitions & Material Fusion

Apply Two-Shot Injection Molding for Seamless Color Transitions & Material Fusion

When product teams need parts that look premium, feel great, and survive harsh use-cycles, two-shot (2K) injection molding delivers—all in a single, lights-out press cycle. By injecting two different resins (or colors) sequentially inside the same mold, you create a fully bonded component that eliminates paint lines, secondary assembly, and weak adhesive joints.

1 What Is Two-Shot Injection Molding?

-

Shot #1 – Substrate

A rigid or structural resin (e.g., PC/ABS, GF-Nylon) fills cavity set A. -

Index / Rotate

The core side turns or slides so the first shot aligns with cavity set B. -

Shot #2 – Overcoat / Accent

A second resin (soft TPE, contrasting color PC, or clear PMMA) injects over designated zones. -

Cooling & Ejection

Both materials solidify together, exiting the press as a single, inseparable part.

Because the second shot bonds while both materials are molten, you achieve chemical fusion and perfect color alignment—no gaps, no paint masks, no glue.

2 Key Advantages for Designers & OEMs

| Benefit | Why It Matters |

|---|---|

| Seamless Color Transitions | High-gloss bezels, logos, or indicator windows molded right into the part—zero post-paint defects. |

| Multi-Material Ergonomics | Soft-touch grips, vibration damping, or in-mold sealing without extra hardware. |

| Lower Part Count | Combine two to six separate SKUs into one molded piece, cutting assembly labor 30-50 %. |

| Tighter Tolerances | Single clamp cycle removes stack-up errors typical of snap-fit or screw-on assemblies. |

| Improved Sustainability | No paint, solvents, or adhesive off-gassing; less scrap and shipping weight. |

3 Design Best Practices

-

Choose Compatible Resins — Consult supplier adhesion charts (e.g., PC + TPU, ABS + SEBS).

-

Balance Wall Thickness — Shot #2 walls ≈ 60–100 % of shot #1 to avoid sink.

-

Add Mechanical Locks — Through-holes, dovetail ribs, or undercuts safeguard bond strength under heat cycling.

-

Gate Wisely — Place gates on the thickest section of the overcoat to minimize knit lines.

-

Simulate Early — Run 2K Moldflow to predict flow fronts and cooling deltas before steel is cut.

4 Ideal Applications & Industries

| Industry | Typical Two-Shot Parts |

|---|---|

| Consumer Electronics | Smartwatch bezels, earbud shells, phone buttons |

| Automotive Interiors | Soft-feel HVAC dials, illuminated symbols, piano-black switch bezels |

| Medical Devices | Injector housings, catheter hubs, ergonomic grips |

| Power Tools | Dual-durometer handles, trigger boots, battery covers |

| Home Appliances | Mixer knobs, dishwasher rack feet, coffee-machine panels |

5 Case Snapshot – Smartwatch Bezel with Light Guide

| Metric | Single-Shot + Paint | Two-Shot PC/ABS + Clear PMMA |

|---|---|---|

| Cosmetic Scrap | 11 % (dust, drip) | 2 % |

| Assembly Time | 1.8 min (glue lens) | 0 min |

| Water-Ingress Failures | 4 % | <0.5 % |

| Total Part Cost | $2.31 | $1.84 |

The OEM saved $94 K on a 200 K-unit run and met a 10-week retail launch window.

6 Bring Your 2K Concept to Life—Fast

Taiwan’s mold-making ecosystem pairs Tier-1 precision with agile lead times. Through TaiwanMoldMaker.com you can tap:

-

48-Hour DFM Pack – gating, shut-off, adhesion lab plan, cost model

-

Bridge-to-Steel Tool Credits – roll aluminum pilot tooling into multi-cavity H13 production molds

-

Press Fleet 60–450 t – micro-medical parts to rugged handheld enclosures

-

Live MES Dashboards – monitor CpK, OEE, and OTIF in real time

Explore Our 2K & Complementary Services

-

✔️ Custom Mold and Design Maker – Concept-to-steel engineering for unique 2K layouts

-

✔️ Mold Service – Turnkey development, T-0 to PPAP

-

✔️ Injection Mold – High-precision steel molds built for millions of cycles

-

✔️ Two-Shot Molding Services – Rotary and index-plate production up to three colors

-

✔️ Overmolding Solutions – Insert soft seals or metal cores in one clamp cycle

-

✔️ Customer Examples – Real success stories in automotive, electronics, and medical

7 Next Steps

-

Upload Your CAD & Resin Targets (STEP, IGES, or native files).

-

Book a 30-min Virtual DFM Review to finalize gates, shut-offs, and cosmetic zones.

-

Approve Dual-Path Quote—aluminum bridge tool + steel production tool.

-

Receive T-0 Parts in as Fast as 3 Weeks—ready for lab, field, or retail testing.

Ready for flawless color transitions and material fusion?

Get your no-obligation DFM and timeline within 48 hours.

Final Takeaway

Two-shot injection molding transforms ordinary parts into visually striking, ergonomically superior components—without extra paint lines, screws, or adhesives. Partner with TaiwanMoldMaker.com to compress lead times, slash assembly costs, and hit the market with products that look as advanced as they perform.