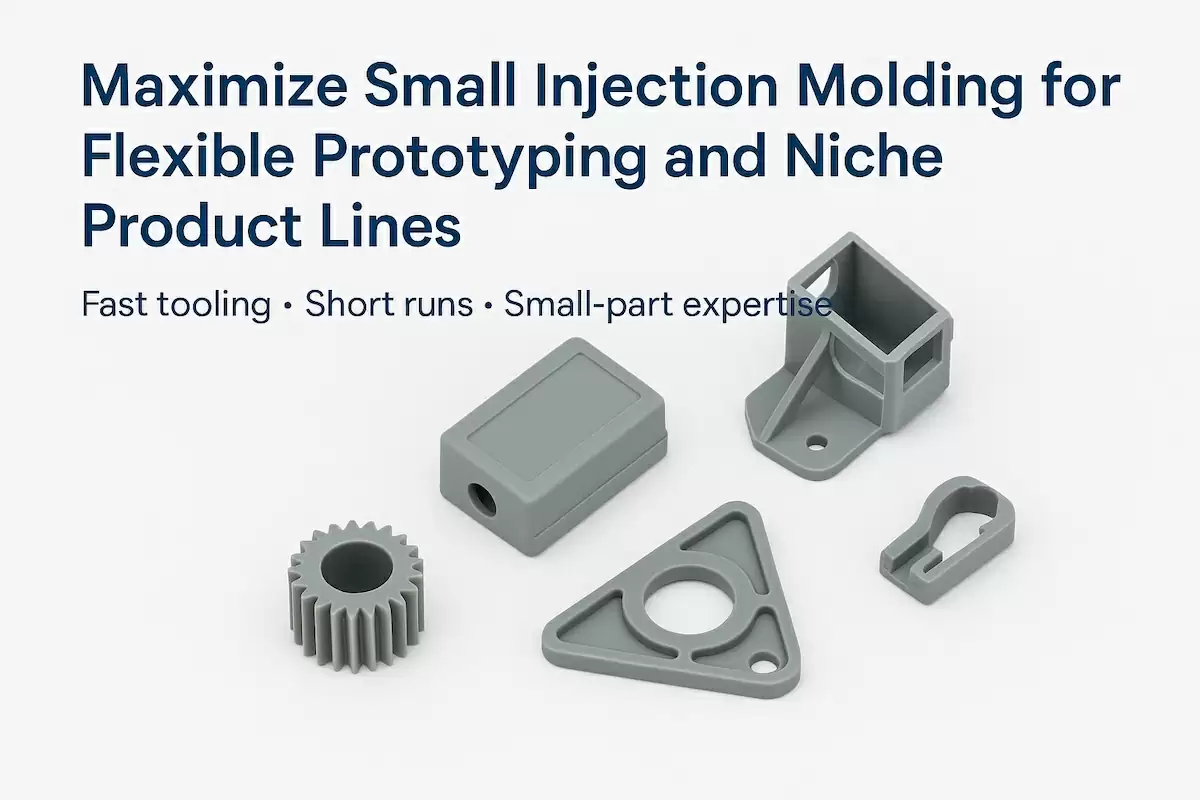

Maximize Small Injection Molding for Flexible Prototyping and Niche Product Lines

Maximize Small Injection Molding for Flexible Prototyping and Niche Product Lines

Maximize Small Injection Molding for Flexible Prototyping and Niche Product Lines

Fast tooling • Short runs • Small-part expertise

When you’re exploring new ideas, validating a market, or serving niche customers, you don’t always need a 400-ton press and a 16-cavity tool. Maximize small injection molding for flexible prototyping and niche product lines and you get shorter setup times, lower investment, and the freedom to tweak designs without blowing your budget.

The TaiwanMoldMaker.com network uses small-tonnage, quick-change cells and modular tooling to turn low-to-medium volume ideas into production-ready parts—on time, on spec.

Explore our end-to-end services:

Custom Mold & Design Maker → Mold Service → Injection Mold → Molding → Customer Examples → Contact

What “small injection molding” really means

In this context, “small” refers to both press size and order size:

-

Press tonnage: Typically 15–120 tons, ideal for micro components, small housings, gears, clips, connectors, and precision inserts.

-

Order quantities: From dozens to a few tens of thousands of parts per year per SKU.

-

Tooling style: Single or 2-cavity tools, MUD frames, insert tools, and micro-molds that minimize steel and machining.

The goal: production-grade parts in real materials, without the cost and lead time of big tools and big machines.

When small injection molding is the right choice

-

Early-stage products & MVPs

Validate fit, function, and user feedback before committing to multi-cavity steel. -

Niche and premium product lines

High value, lower volume SKUs (e.g., specialty medical accessories, pro-grade camera parts, custom connectors). -

Frequent design changes

Small tools and single-cavity layouts are quicker to modify when you’re still iterating. -

Legacy & service parts

Keep older equipment supported without stocking years of inventory. -

Localized / pilot builds

Launch quickly in one region, then scale with copy-cavity tools once demand is proven.

How we maximize flexibility on small presses

1. Quick-change tooling

-

MUD / insert tooling: A shared mold base with interchangeable inserts cuts tooling cost and allows ultra-fast changeovers.

-

Standardized connections: Water, hydraulics, electrics, and EOAT interfaces are common across cells.

-

SMED practices: Pre-staged tools, preset recipes, and color-flush SOPs keep setup time low.

2. Smart tool design for short runs

-

Aluminum or hybrid steel tools where appropriate for speed and cost.

-

Hand-loads instead of complex slides for limited undercuts—perfect for low volumes.

-

Replaceable inserts at high-wear features so you don’t rebuild the whole tool after changes.

3. Automation scaled to need

-

Robot take-out for delicate or micro parts to avoid damage.

-

Simple nests & trays for manual packaging when automation isn’t yet justified.

-

Ability to upgrade the cell later (vision, leak test, laser marking) when the product line grows.

Design-for-manufacturing (DFM) tips for small parts and short runs

-

Keep walls uniform

Aim for 1.0–2.5 mm walls on small parts; use ribs instead of thick sections to avoid sinks and long cycles. -

Add draft everywhere you can

≥1–2° on all vertical faces; more on textured or soft-material surfaces to ensure smooth ejection. -

Use generous radii

Eliminate sharp corners that trap stress or interfere with flow—micro parts are especially sensitive. -

Standardize bosses and holes

Use common diameters and depths for threads/inserts so tooling is easier and cheaper. -

Think multi-use bodies

Design a shared “core” with small insert changes for logos, port counts, or mounting patterns across SKUs.

We wrap these into a 48-Hour DFM Pack (flow/cool/warp + risk log) before we cut steel.

Material options for small injection molding

Even at low volumes, you can (and should) use production-grade resins:

-

ABS / PC-ABS – small housings, covers, knobs.

-

PP / PE – caps, closures, disposable medical & labware.

-

PC / PMMA / COC/COP – clear windows, lenses, microfluidic chips.

-

POM / PA / PBT – gears, latches, bearings, clips, electrical connectors.

-

TPE / TPU – overmolded grips, seals, strain reliefs on cables.

We’ll help you trade off cost, strength, regulatory approvals, and appearance for each niche product line.

Cost and lead-time: what to expect

-

Tooling investment:

-

Lower with MUD frames and aluminum/hybrid tools.

-

Incremental insert changes instead of full-new tools for design updates.

-

-

Piece price:

-

Higher than mass-production multi-cavity tools, but offset by

-

No dead inventory,

-

Fewer design loops,

-

And faster time-to-market.

-

-

-

Typical small-tool timeline:

-

Day 0–2: 48-Hour DFM & risk pack.

-

Day 3–10: Tool build (Al/MUD or hybrid steel), simple EOAT/fixtures.

-

Day 11–13: T0 in production resin; gate-freeze, weight ladder, initial cosmetics.

-

Day 14–15: T1 + FAIR + CMM/scan; ship first-article parts.

-

Need quick-cut steel or more complex actions? Expect roughly Day 3–20/28 depending on geometry.

Scaling up from “small” when demand grows

Small injection molding doesn’t trap you—it gives you a low-risk on-ramp:

-

Start with single-cavity MUD or aluminum for prototyping and pilot.

-

Lock design and process window using scientific molding (cavity pressure, DOE, CpK).

-

Move to multi-cavity or family tools in hardened steel once orders increase.

-

Optionally copy-cavity to other plants (Taiwan + SE Asia) for regional supply and surge capacity.

Your early tools aren’t wasted—they become support tools, engineering tools, or backup capacity.

RFQ checklist (copy/paste to prevent back-and-forth)

When you’re ready to talk about small injection molding, send us:

-

Project name and target launch date

-

CAD files: 3D (STEP/IGES) + 2D with key dimensions and tolerances

-

Estimated volumes per SKU

-

Prototype / pilot quantity

-

12-month forecast

-

-

Material requirements (resin family or property targets; certifications if any)

-

Cosmetic level (basic, consumer-grade, high-gloss, clear) and any texture codes

-

Special needs: overmold, inserts, clean room, ESD, packaging style

-

Budget preference: lowest upfront tooling vs. long-term unit-cost optimization

Send your brief here → Contact

Why use the TaiwanMoldMaker.com network for small injection molding?

-

Small-tonnage, quick-change cells tailored to prototypes and niche products.

-

Tooling strategies (MUD, inserts, aluminum/hybrid steel) that keep investment under control.

-

Scientific molding and MES data even on short runs, so you can scale confidently later.

-

One accountable team from concept and DFM to T0/T1, ramp, and copy-cavity scaling.

Start here:

Injection Mold → Molding → Mold Service → Customer Examples → Contact