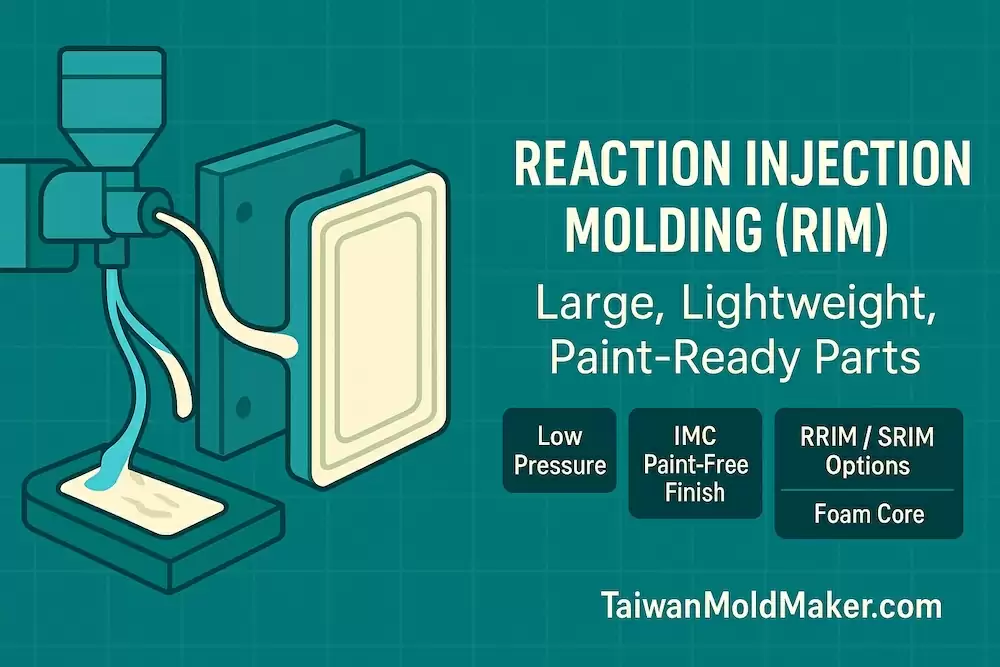

Reaction Injection Molding (RIM) for Large, Lightweight, Paint-Ready Parts

Reaction Injection Molding (RIM) for Large, Lightweight, Paint-Ready Parts

Reaction Injection Molding (RIM): Low-Pressure Molding for Large, Lightweight Parts

Reaction Injection Molding (RIM) mixes two low-viscosity liquid components—typically polyol and isocyanate (or polyurea systems)—inside a high-precision mix head, then injects the reactive blend into a heated mold where it polymerizes in-mold. Because the liquids are thin and the process runs at low pressure, RIM excels at large, thick-section, lightweight parts with reduced residual stress and comparatively lower tooling cost than traditional high-pressure injection.

When to Choose RIM

-

Large envelopes & complex skins: appliance covers, kiosk housings, medical carts, equipment shrouds, EV body panels, bumper fascias.

-

Thick sections (3–25+ mm): structural ribs often unnecessary; foam cores reduce print-through.

-

Lower clamp force available: low-pressure fill reduces machine tonnage requirements.

-

Cosmetic flexibility: paint-ready surfaces with in-mold coating (IMC) options for Class-A finishes.

-

Lightweight stiffness: RRIM/SRIM (chopped glass or fiber mats) boost modulus without heavy parts.

RIM Family at a Glance

| Process | Matrix | Reinforcement | Best For | Notes |

|---|---|---|---|---|

| RIM (PU/PUA) | Polyurethane / Polyurea | None | Large cosmetic skins | Low pressure, paint friendly |

| RRIM | PU/PUA | Chopped glass, mica | Impact-resistant panels | Stiffness ↑, cycle ↑ |

| SRIM | PU | Glass fiber mats/preforms | Structural shells/covers | Highest stiffness; preform tool required |

| Foam RIM | PU foam | None | Thick, lightweight parts | Lower density, good damping |

Design Rules (Quick Wins)

-

Wall thickness: 3–12 mm typical; 25 mm+ possible (foam).

-

Radii: generous internal ≥3 mm to promote flow and strength.

-

Draft: 1–3° on most faces; more for deep textures.

-

Ribs/Bosses: often minimized—foam core and skin carry stiffness; use pads/landings for fasteners.

-

Inserts: brass/steel inserts mold-in readily; design poka-yoke nests.

-

Tolerance: looser than thermoplastics on very large parts; plan datum-based fixtures and trim jigs.

-

Bonding & assembly: mechanical fasteners, adhesives, or IMC tie-coats for paint.

Typical Process Window (Starting Points—tuned per system)

| Parameter | Range | Notes |

|---|---|---|

| Mold temperature | 50–80 °C | Higher mold temp → improved skin & cure |

| Mix pressure | ~10–20 MPa in head | Low clamp tonnage at mold |

| Fill time | 2–10 s | Fast to avoid knit/cure lines |

| Gel time | 3–30 s | Chemistry-dependent |

| Demold | 60–240 s | Part size, chemistry, temperature drive cure |

| Density | 0.6–1.2 g/cm³ | Foam vs solid skins |

Controls: component temperature, ratio accuracy (±0.5–1.0%), mix head maintenance, mold venting/vacuum assist.

Tooling & Cell Architecture

-

Molds: aluminum or nickel shell with backing; low-pressure build reduces cost vs. steel injection tools.

-

Coatings/liners: hard-coat for abrasion, release agents; IMC for paint-free gloss and scratch resistance.

-

Gating & vents: fan/film gates with distributed venting; vacuum assist for long flows and knit-line control.

-

Reinforcement handling:

-

RRIM: in-line chopper feeds glass into the stream.

-

SRIM: dedicated preform tool for mats; robot placement improves repeatability.

-

-

Automation: robot demold, in-cell trimming/edge routing, primer/paint booths, vision cosmetics.

-

Quality hooks: shot mass & ratio logs, gel/demold timers, temperature/pressure signatures, paint adhesion pull tests.

RIM vs. Thermoplastic Injection vs. SMC (Buyer’s Cheat Sheet)

| Attribute | RIM (PU/PUA) | Thermoplastic Injection | SMC/Compression |

|---|---|---|---|

| Tooling cost | Low–Medium | High | Medium |

| Part size/thickness | Excellent (large, thick) | Medium (warpage risk on thick) | Excellent |

| Pressure/tonnage | Low | High | Medium |

| Cycle time | Medium | Fastest | Slow–Medium |

| Stiffness/weight | Good (↑ with RRIM/SRIM) | Good; ribs required | High but heavier |

| Cosmetics | Paint-ready; IMC | Excellent (texture & gloss) | Paint required |

| Tight tolerances | Medium | Best | Medium |

| Capex to scale | Low–Medium | High | Medium |

Quality & Compliance

-

Metrology first: large-part checking fixtures, blue-light scanning for surface deviation.

-

Mechanical: Shore hardness, flexural modulus/strength, IZOD/Charpy (if required).

-

Surface/paint: grid tape-pull, cross-hatch adhesion, gloss/ΔE, orange-peel rating.

-

Process capability: SPC on ratio, shot mass, gel/demold, mold temp; CpK on critical dimensions.

-

Safety/ESG: isocyanate handling SOPs, ventilation, VOC control for paints/IMC.

Typical Outcomes with Optimized RIM Cells

| KPI | Baseline | Optimized RIM Cell |

|---|---|---|

| Paint rework | 6–8% | ≤2% with IMC + temp control |

| Cycle (1 m² fascia) | 180 s | 120–150 s (chemistry + mold temp) |

| Warp at datum | 1.5–2.0 mm | ≤0.8–1.0 mm with vacuum/vent tuning |

| Adhesion failures | Occasional | Zero after IMC & bake window lock |

Representative; geometry and chemistry dictate actuals.

RFQ Template (Copy/Paste)

Subject: RFQ – Reaction Injection Molding (RIM) Program

Attachments: STEP/IGES + 2D with CTQs & cosmetic map

-

Part name / envelope size / target mass:

-

Annual volume & first PO qty:

-

Chemistry target: (PU / polyurea; solid / foam / RRIM / SRIM; Shore hardness)

-

Cosmetic plan: (paint vs. IMC; color/gloss targets; texture or grain)

-

Inserts & assembly: (mold-in inserts, adhesive/fascia bonding, trim edges)

-

Critical tolerances & functional tests: (flatness, stiffness, impact, load)

-

Fixtures needed: (checking fixture, trim/routing, assembly jigs)

-

Compliance: (RoHS/REACH, flame/UV specs, paint VOC)

-

Packaging & logistics: (racks, protective films, label spec)

-

Target dates: (T0/T1, paint buy-off, SOP)

-

Known risks: (knit lines, sink/print-through, long flow)

What We Provide (TaiwanMoldMaker.com Network)

-

DFM in 48 hours: gate/vent/vacuum plan, IMC/paint stack, cure model, and risk map.

-

Tooling: aluminum or nickel shell molds; RRIM chopper or SRIM preform tools.

-

Process: chemistry selection, ratio/temperature control, vacuum & vent tuning, scientific trials to lock gel/demold window.

-

Finishing: in-cell trimming, primer/paint or in-mold coating; vision cosmetics.

-

Documentation: FAIR, fixture gauges, paint adhesion/gloss records, SPC charts; MES hooks for traceability.

Quick Links

-

Custom Mold & Design Maker

https://www.taiwanmoldmaker.com/product/custom-mold -

Mold Service

https://www.taiwanmoldmaker.com/product/mold-service -

Injection Mold

https://www.taiwanmoldmaker.com/product/injection-mold -

Customer Examples

https://www.taiwanmoldmaker.com/product/customer-examples

Call to Action

Evaluating RIM for a large, paint-ready housing or fascia? Send your CAD and volume targets to receive a 48-Hour RIM DFM & Cost Pack—including chemistry options, cure model, IMC/paint plan, and a realistic launch timeline.

Request an Instant Quote → https://www.taiwanmoldmaker.com/contact