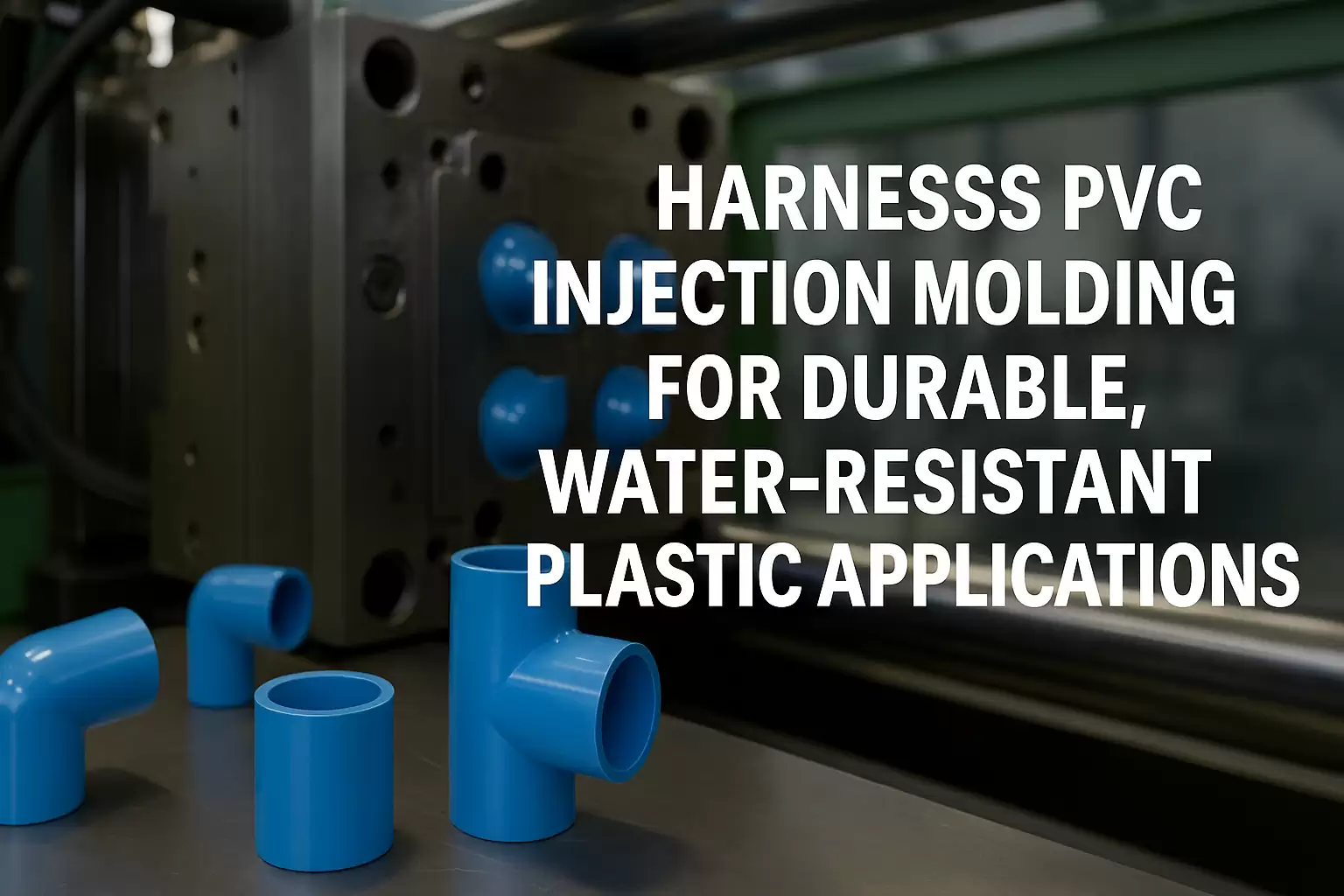

Harness PVC Injection Molding for Durable, Water‑Resistant Plastic Applications

Harness PVC Injection Molding for Durable, Water‑Resistant Plastic Applications

Polyvinyl chloride (PVC) is best known for its excellent moisture barrier, chemical resistance, and long‑term durability—qualities that make it indispensable in plumbing, medical, and outdoor electrical systems. When processed through precision PVC injection molding, the material can be transformed into complex, tight‑tolerance components that outperform many commodity resins in wet or corrosive environments. Below, we explore PVC’s unique properties, design considerations, and the value of partnering with Taiwan‑based INTERTECH (https://www.taiwanmoldmaker.com) to realize high‑performance, water‑resistant parts.

1 Key Material Benefits of PVC

| Property | Typical Value | Application Advantage |

|---|---|---|

| Water & Vapor Barrier | < 0.2 g/m²∙24 h (ASTM E96) | Excellent for fluid delivery and outdoor housings |

| Chemical Resistance | Resistant to acids, bases, salts | Suitable for chemical pumps & labware |

| Flame Retardancy | Self‑extinguishing, UL 94 V‑0 | Meets electrical conduit & panel standards |

| High Dielectric Strength | ~40 kV/mm | Insulates wiring, junction boxes |

| UV & Weather Stability (with additives) | > 5 000 h QUV | Outdoor signage, irrigation fittings |

2 Design & Processing Considerations

-

Ventilation & Corrosion Control – PVC releases HCl at high temps; INTERTECH employs stainless‑steel (420/S136) molds and chromium‑plated runners.

-

Screw & Barrel Design – Low‑compression screws minimize shear heating, preserving polymer integrity.

-

Mold Temperature – 20 – 60 °C for rigid PVC; cooling circuits balanced to avoid sink.

-

Shrinkage Allowance – 0.4 – 1.0 %, lower than PP or HDPE, enabling tight tolerance parts.

-

Metal Inserts / Overmolding – Brass or stainless inserts enhance thread strength; in‑press preheating prevents stress cracking.

3 Common PVC Injection‑Molded Products

| Sector | Part Example | Why PVC? |

|---|---|---|

| Plumbing & HVAC | Pipe fittings, pump housings | Moisture/chemical resistance, UL compliance |

| Electrical | Conduit elbows, junction boxes | High dielectric + self‑extinguishing |

| Medical | Drip chambers, fluid line connectors | USP Class VI grades available |

| Agriculture | Irrigation nozzles, hose couplers | UV‑stabilized against sun exposure |

| Consumer Goods | Outdoor furniture caps, waterproof cases | Weatherability & color stability |

4 Sustainability Note

PVC is fully recyclable via mechanical grinding. INTERTECH can integrate up to 15 % post‑industrial PVC regrind without impacting UL or ISO properties—reducing raw‑material cost and environmental footprint.

5 INTERTECH’s PVC Injection Molding Capabilities

-

Press range 80 t – 400 t equipped with PVC‑dedicated screws & barrels.

-

Stainless‑steel & chrome‑plated molds to combat halogen corrosion.

-

In‑house mold design & CNC machining for rapid prototype to production tools.

-

ISO 9001 & ISO 13485 quality systems ensure medical and industrial compliance.

-

Value‑added operations: ultrasonic welding, solvent bonding, leak‑testing rigs.

Learn more on our custom molding page or explore our tooling services.

Conclusion

By leveraging PVC injection molding, manufacturers obtain durable, flame‑retardant, and water‑resistant components perfectly suited for harsh environments. INTERTECH’s specialized equipment, corrosion‑resistant tooling, and process expertise ensure your PVC parts meet stringent performance and regulatory requirements—on time and within budget.

Have a moisture‑critical application? Contact INTERTECH for a PVC feasibility review and fast quotation.