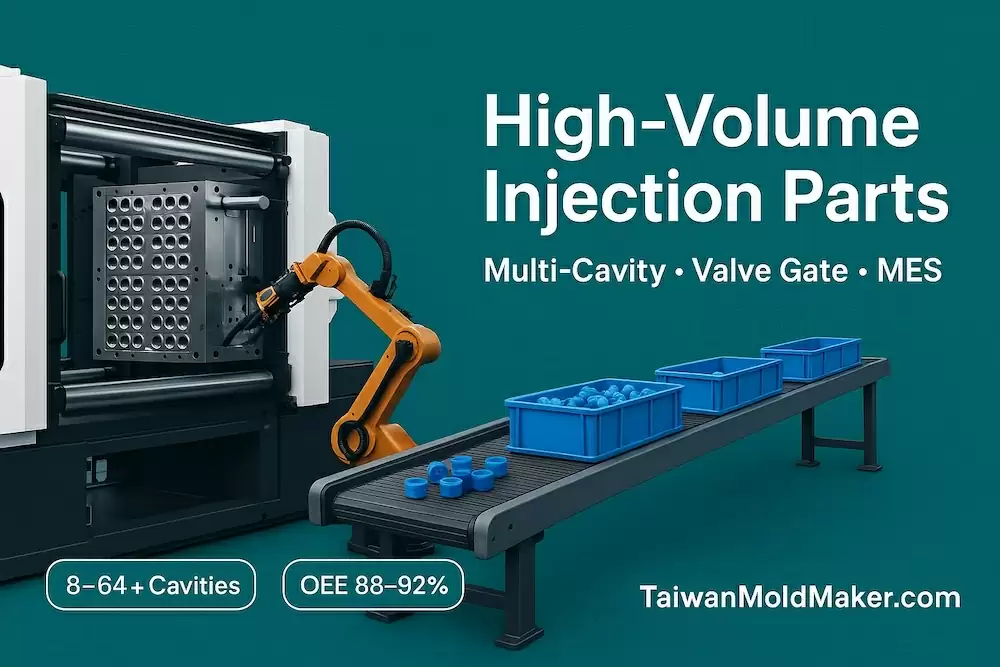

Drive Production of Plastic Injection Parts to Meet High-Volume Consumer Needs

Drive Production of Plastic Injection Parts to Meet High-Volume Consumer Needs

Drive Production of Plastic Injection Parts to Meet High-Volume Consumer Needs

Fast-moving consumer markets demand millions of identical parts, stable cosmetics, and on-time fill rates—without runaway costs. TaiwanMoldMaker.com’s partner network combines multi-cavity tooling, hot-runner precision, and automation with MES to deliver high-volume plastic injection parts that stay in-spec and on schedule.

What High-Volume Success Requires

-

Output at cost: multi-cavity (8–64+), engineered balance, optimized cycles

-

Cosmetics at speed: valve/sequence control, RHCM where needed, texture strategy

-

Uptime & yield: robotic demold, auto degate, closed-loop process guards

-

Proof for auditors: CpK at CTQs, ΔE/gloss control, traceable lots

-

Logistics alignment: call-offs, EDI/ASN, retail-ready/eco packaging

Cell Architecture for Millions of Shots

-

Press Class: 150–650T for small/medium parts; larger presses available for totes, housings

-

Tooling: H13/S136 steels, valve-gated hot runners, manifold thermal mapping

-

Cooling: parallel circuits, ΔT ≤ 5 °C, conformal inserts on hot spots

-

Automation: 3- to 6-axis EOAT, insert loading, inline pad/laser mark, ultrasonic weld

-

Vision SPC: 100% gate vestige / flash / short-shot detection; seam control for overmolds

-

MES & APIs: live OEE, CpK, scrap, and genealogy shared with your ERP/MES

Tooling & Process Playbook

| Need | Best Practice | Benefit |

|---|---|---|

| High cavity counts (caps, closures) | Valve-gated, naturally balanced runners | Even fill, low stringing, fast cycles |

| Large cosmetic skins | Sequential valves / RHCM | Weld-line control, paint-free gloss |

| Thin-wall parts | High-speed fill + fan gates | Strength at lower clamp tonnage |

| Mixed variants | Family molds or swap inserts | Shared base, lower capex per SKU |

| Soft-touch grips | 2K/overmolding with seam vision | Integrated feel, fewer assemblies |

| Thick-section parts | Gas-assist / structural foam | Sink ↓, weight ↓, stiffness ↑ |

Quality at Scale (Consumer-Grade to Regulated)

-

Scientific molding DOE with cavity pressure for V/P transfer

-

Metrology first: FAIR + CMM/blue-light, GR&R at CTQs

-

Color & surface: ΔE targets, gloss/orange-peel mapping, SPI textures

-

Compliance: ISO 9001 network; IATF 16949 / ISO 13485 at select plants

-

SPC: recipe guards, alarm limits, automatic hold-and-sort logic

Typical Throughput & Cost Gains

| KPI | Before (Generic Cell) | Optimized High-Volume Cell |

|---|---|---|

| Cycle (PP consumer lid) | 10.4 s | 8.1–8.6 s |

| Scrap | 2.0–3.5% | ≤ 0.8–1.2% |

| OEE | 70–75% | 88–92% |

| Energy (kWh/kg) | 0.55 | 0.40–0.45 |

Outcomes vary by geometry, resin, and tool design; numbers are representative.

Design-for-Volume Tips (Copy/Paste)

-

Uniform walls; ribs at 40–60% of wall; core heavy bosses

-

Draft: ≥ 1.0–1.5° textured; ≥0.5° polished

-

Gate strategy: place off A-class faces; fan/film for skins; sequential for long flows

-

Bosses: ID ≈ 60–70% OD; fillet base; tie into walls with ribs

-

Overmolds: lock substrate grade & TPE chemistry; define bond targets (peel/shear)

-

Color control: masterbatch spec, residence-time limits, ΔE acceptance plan

Ramp-to-SOP Roadmap

-

Upload CAD & volumes (NDA protected)

-

48-Hour DFM Pack: gating/cooling map, risk register, cycle & CPU ladder

-

Tool kick-off: hot-runner balance, conformal cooling where ROI is positive

-

Trials (T0/T1/T2): DOE + cavity-pressure curves → golden recipe

-

Qualification: capability at CTQs, cosmetics buy-off, packaging line test

-

SOP & Scale: EDI/ASN, kanban call-offs, dual-plant surge capacity

Logistics Built for Retail Timelines

-

Call-off replenishment with safety-stock rules

-

Retail-ready packs (barcodes, QR to inspection pack, recycled cartons)

-

Carton/pallet maps to minimize damage and speed receiving

-

Dual-lane capacity (Taiwan + SE Asia) for continuity and promotions

RFQ Template (High-Volume Focus)

Subject: RFQ – High-Volume Injection Parts (Consumer)

Attachments: STEP/IGES + 2D with CTQs & cosmetic map

-

Part name / revision:

-

Annual volume & first order qty: (e.g., 8M/yr; first PO 500k)

-

Resin & color (grade/MFR; FR/UV/food-contact):

-

Cosmetic class & texture (SPI code, ΔE tolerance):

-

Tooling preference (cavity count, family vs. dedicated, 2K/overmold):

-

Quality pack (FAIR, CMM, ΔE/gloss, capability, PPAP if needed):

-

Packaging (unit pack, carton/pallet map, label spec/retailer):

-

Logistics (Incoterms, call-off/EDI, ASN):

-

Target dates (T1, buy-off, SOP):

-

Known risks (weld-line areas, hinge life, clip retention, etc.):

Related Services & Quick Links

-

Custom Mold & Design Maker – rapid DFM & tooling strategy

https://www.taiwanmoldmaker.com/product/custom-mold -

Mold Service – aluminum, hybrid, and full steel tooling

https://www.taiwanmoldmaker.com/product/mold-service -

Injection Mold – materials & processes overview

https://www.taiwanmoldmaker.com/product/injection-mold -

Molding – automated cells with MES traceability

https://www.taiwanmoldmaker.com/product/molding -

Customer Examples – case snapshots and results

https://www.taiwanmoldmaker.com/product/customer-examples

Call to Action

Need a dependable engine for high-volume consumer parts? Send CAD and target volumes to receive a 48-Hour DFM & Cost Pack with gating plan, cycle model, and ramp schedule.

Request an Instant Quote →

https://www.taiwanmoldmaker.com/contact