Water Spigot & Pipe-Fitting Mold Parts | Intertech Case Study for K. Prevx (Nordics)

Water Spigot & Pipe-Fitting Mold Parts | Intertech Case Study for K. Prevx (Nordics)

Intertech Helps K. Prevx Build Precision Mold Parts for Water Spigot & Pipe-Fitting Programs

Scalable capacity • Tight tolerances • Fast delivery (30–45 days)

When K. Prevx—a leading manufacturer of water spigot products for kitchens, bathrooms, and air-conditioning in Finland, Scandinavia, and Northern Europe—needed a reliable partner for mold parts and full pipe-fitting molds, they chose Intertech. Beginning in 2013, we supplied a wide range of precision components and turnkey molds on compressed timelines while meeting strict European quality expectations.

Explore how we go from DFM to validated production:

Custom Mold & Design Maker • Mold Service • Injection Mold • Molding • Customer Examples • Contact

Customer Background

K. Prevx builds premium water spigots and fittings used in residential and HVAC applications across Nordic markets. Referred by one of their own customers, the K. Prevx team engaged Intertech to manufacture a broad set of mold parts and complete pipe-fitting molds—with short delivery windows of 30–45 days.

Scope of Supply (Representative)

Precision mold parts

-

Mold bases, guide pillars, guide bars

-

Spigot and core components

-

Mold accessories and serviceable inserts

Complete pipe-fitting molds (tool + components)

-

Access pipe Ø50 mm and Ø110 mm

-

Reducer Ø110→50 mm

-

Bend Ø40–87.5°

-

Branch Ø110 mm

-

Single socket Ø110 mm

-

Mold base + collapsible core assembly for fast demold and easy maintenance

→ Learn more about our modular tooling options: Injection Mold • End-to-end build support: Mold Service

Engineering Approach

-

Material & Heat Treatment

All steel was hardened and heat-treated, sourced from Germany, Sweden, and Japan. We provided steel certificates and traceability with every shipment. -

Tight Tolerance, High Precision

Components were machined to close tolerances for concentricity, sealing faces, and thread accuracy—essential for water-tight fittings and stable assembly.

→ See how we validate tolerance stacks on press: Molding -

Collapsible Core Design

Our in-house collapsible core reduces ejection complexity, shortens cycle time, and slashes maintenance cost. It’s easy to replace and service without a full tool tear-down—one reason K. Prevx continues to send repeat orders. -

Documentation & QA

Each delivery included inspection records, material certificates, and packing lists. We can also provide FAIR/CMM and GR&R on request.

→ Explore typical QA packs: Customer Examples

Results

-

30–45 day delivery windows met across multiple SKUs

-

Robust collapsible core solution that simplifies demold & maintenance

-

Repeat orders from K. Prevx based on performance, precision, and service

-

Clean, anti-rust packing in fumigated wooden crates for global shipping reliability

→ Ready to scope your project? Request an Instant Quote

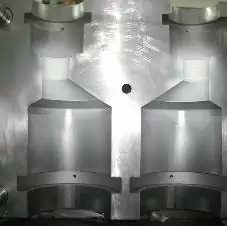

Project Gallery (Attached Photos)

-

Photo A — Pipe-fitting mold cores & shut-offs (detail):

-

Photo B — Multi-cavity pipe-fitting tool face (detail):

Why Intertech for Water Spigot & Fittings

-

Tooling depth: valve-gated hot runners, collapsible cores, precision sealing faces

-

Speed: 48-Hour DFM & Cost Pack and rapid machining/HT routes

-

Repeatability: scientific molding methods, capability at CTQs, and serviceable inserts

-

Global logistics: export-ready crates, anti-rust packing, and complete paperwork

Dive deeper into our services:

Custom Mold & Design Maker • Injection Mold • Molding • Customer Examples

Call to Action

Planning a water spigot or pipe-fitting program? Send your CAD and target specs to receive a 48-Hour DFM & Cost Pack—gating/cooling plan, cycle estimate, and a maintenance-friendly collapsible-core concept.

→ Contact Us for an Instant Quote