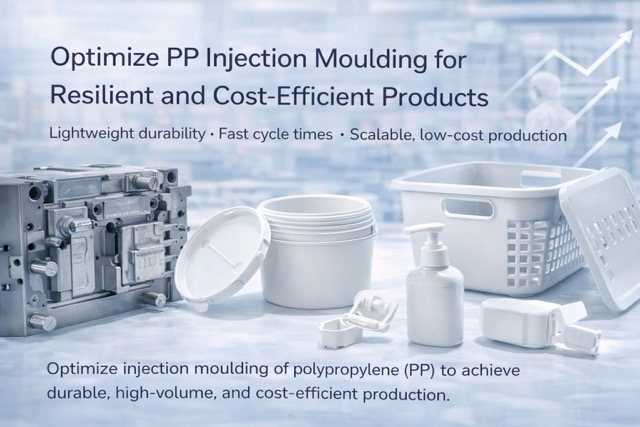

Optimize PP Injection Moulding for Resilient and Cost-Efficient Products

Optimize PP Injection Moulding for Resilient and Cost-Efficient Products

Optimize PP Injection Moulding for Resilient and Cost-Efficient Products

Lightweight durability • Fast cycle times • Scalable, low-cost production

Polypropylene (PP) is one of the most widely used thermoplastics in injection moulding due to its excellent balance of toughness, flexibility, chemical resistance, and cost efficiency. When processed correctly, PP enables manufacturers to produce high-volume, durable parts with short cycle times and competitive unit costs.

At TaiwanMoldMaker.com, we help customers optimize PP injection moulding through engineering-led DFM, purpose-built tooling, and stable production processes—ensuring products are resilient in use and efficient to manufacture.

Why polypropylene (PP) is ideal for injection moulding

PP is a preferred material across consumer, industrial, and packaging applications because it offers:

-

Low material cost and wide global availability

-

Excellent fatigue resistance (ideal for living hinges)

-

Good chemical and moisture resistance

-

Lightweight properties with sufficient impact strength

-

Fast processing and short cooling cycles

These advantages make PP especially attractive for cost-sensitive, high-volume programs.

Typical applications of PP injection moulding

Optimized PP injection moulding is commonly used for:

-

Consumer product housings and enclosures

-

Packaging components and containers

-

Living-hinge parts (caps, lids, closures)

-

Medical and laboratory disposables (non-implant)

-

Household goods and storage products

-

Industrial components requiring chemical resistance

Examples of molded PP components can be reviewed in Customer Examples.

Key challenges in PP injection moulding

Despite its advantages, PP presents specific processing challenges that must be addressed early:

-

Shrinkage and warpage due to semi-crystalline structure

-

Flow hesitation in thin-wall or long-flow parts

-

Cosmetic sensitivity on visible surfaces

-

Dimensional variation if cooling is not well balanced

This is why process optimization and tooling design are critical for consistent results.

Engineering-led DFM for optimized PP molding

Successful PP injection moulding begins with disciplined DFM:

-

Wall thickness optimization

Uniform walls reduce sink, warpage, and cycle time. -

Gate and runner design

Balanced flow paths minimize differential shrinkage. -

Draft and ejection strategy

Proper draft prevents deformation during ejection. -

Rib and hinge design

Geometry is tuned to maximize strength and fatigue life.

These steps are handled early through Custom Mold & Design Maker to avoid costly rework later.

Tooling strategies for PP injection moulding

Tooling plays a major role in cost and cycle-time optimization:

-

Cold runner systems

Suitable for cost-driven projects with acceptable regrind use. -

Hot runner systems

Reduce material waste, improve consistency, and shorten cycles—often improving ROI at scale. -

Multi-cavity molds

Lower unit cost for high-volume PP products.

Tool design and execution are managed through Injection Mold and coordinated with production planning.

Process optimization for resilient PP parts

To achieve stable quality and efficiency, PP molding requires:

-

Optimized melt temperature and injection speed

-

Controlled packing pressure to manage crystallization shrinkage

-

Balanced cooling layout for dimensional stability

-

Scientific molding methods to define a robust process window

Once validated, parameters are transferred into repeatable production through Molding operations.

Cost-efficiency and ROI considerations

Optimizing PP injection moulding improves ROI by:

-

Reducing cycle time and increasing machine output

-

Lowering material usage through efficient part design

-

Minimizing scrap and rework

-

Extending mold life through appropriate steel selection

Tooling and process decisions are reviewed during Mold Service to align upfront investment with long-term cost targets.

Typical PP injection moulding project timeline

A representative PP program may follow:

-

Day 0–2: DFM review and material confirmation

-

Day 3–10: Tool build (soft or production tooling)

-

Day 11–13: T0 trial and process tuning

-

Day 14–15: T1 samples with inspection reports

-

Day 16+: Volume production ramp

Timelines vary based on cavitation, surface requirements, and validation scope.

RFQ checklist for PP injection moulding

To quote accurately and optimize cost early, please prepare:

-

3D CAD (STEP/IGES) + 2D drawings

-

Target annual volume and product life cycle

-

PP grade preference (homopolymer, copolymer, filled PP)

-

Cosmetic and dimensional requirements

-

Assembly or hinge performance requirements

-

Budget priorities (lowest unit cost vs. fastest launch)

Submit your project details here:

Contact

Why optimize PP injection moulding with TaiwanMoldMaker.com

-

Extensive experience with PP injection moulding across industries

-

Engineering-driven DFM and tooling decisions

-

Flexible strategies from pilot runs to high-volume production

-

Stable quality control and transparent process ownership

-

Proven results demonstrated in Customer Examples

If you are looking to optimize PP injection moulding for resilient and cost-efficient products, TaiwanMoldMaker.com provides the technical expertise and manufacturing discipline needed to deliver consistent quality and strong returns at scale.

Start here:

Custom Mold & Design Maker →

Mold Service →

Injection Mold →

Molding →

Contact