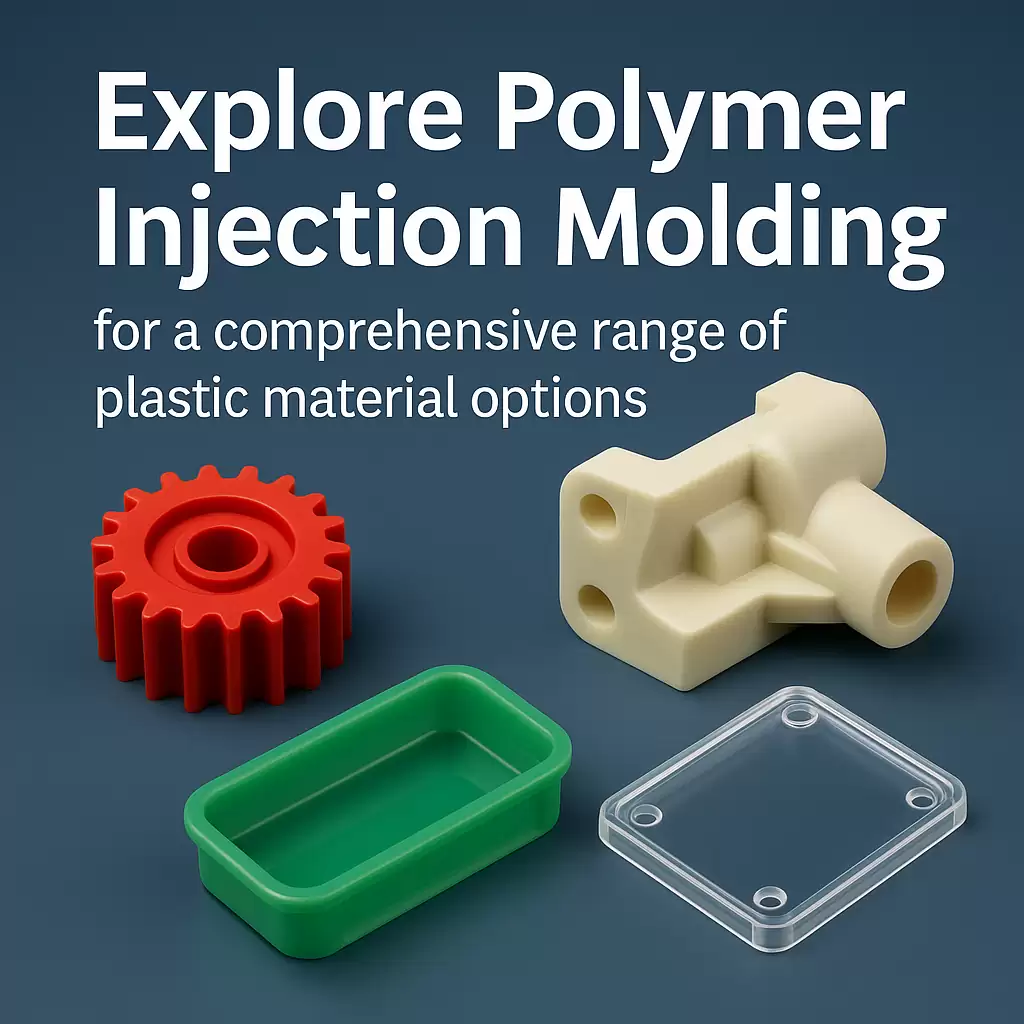

Explore Polymer Injection Molding for a Comprehensive Range of Plastic Material Options

Explore Polymer Injection Molding for a Comprehensive Range of Plastic Material Options

Injection molding is the most versatile platform in plastics manufacturing, capable of processing everything from low-cost commodity resins to aerospace-grade polymers. For product designers and sourcing teams, understanding the material landscape unlocks performance gains, cost savings, and sustainability wins—all while staying within the familiar, scalable framework of polymer injection molding. Below is a tour of the major resin families, the key property levers you can tune with fillers and additives, and a simple selection roadmap to ensure the right plastic ends up in your mold—and on the shelf.

1 Polymer Families at a Glance

| Category | Typical Grades | Core Advantages | Common Drawbacks | Ideal Applications |

|---|---|---|---|---|

| Commodity Thermoplastics | PP, HDPE, PS, PVC | Low cost, fast cycles, chemical resistance | Lower heat & strength ceilings | Housewares, caps, toys |

| Engineering Thermoplastics | ABS, PC, POM, PA 6/66 | Higher impact & modulus, tight tolerances | Mid-range price, drying required | Appliances, gears, enclosures |

| High-Performance Polymers | PEEK, PEI, PPS, LCP | 200 °C+ service temp, chemical & wear resistance | High resin cost, tougher processing | Medical, oil-&-gas, aerospace |

| Thermoplastic Elastomers (TPE/TPU) | SBS, SEBS, TPU, TPO | Rubber-like feel, recyclable | Lower structural rigidity | Grips, gaskets, seals |

| Blends & Alloys | PC/ABS, PC/PBT, PP+GF | Tailored impact + stiffness + aesthetics | Added compounding cost | Automotive interiors, IoT housings |

| Sustainable & Recycled | Bio-PP, rPET, PLA blends | Reduced carbon footprint, brand value | Limited heat, moisture sensitivity | Packaging, eco gadgets |

2 Tuning Properties With Fillers & Additives

| Modifier | What It Adds | Typical Loadings | Watch-Outs |

|---|---|---|---|

| Glass Fiber | 2–5× tensile strength, dimensional stability | 15–50 % | Higher wear on tools, matte finish |

| Carbon Fiber | High stiffness, ESD control, black color | 10–40 % | Brittle in thin ribs |

| PTFE / MOS₂ | Self-lubrication, low friction | 5–15 % | May reduce tensile strength |

| Flame Retardant (UL 94 V-0) | Compliance for electronics | 10–20 % | Possible color shift, higher viscosity |

| UV Stabilizer & Color Masterbatch | Outdoor durability, brand colors | 0.5–2 % | Requires purge discipline |

| Mineral/Talc | Lower CTE, improved scratch | 10–40 % | Can raise part weight |

3 Why Injection Molding Accommodates Such Diversity

-

Precisely Controlled Melt Profiles

Modern servo-electric presses can switch barrel temperatures zone-by-zone, letting you run PP at 210 °C in the morning and PPS at 315 °C that afternoon. -

Modular Tooling & Hot-Runner Systems

Changeable gate inserts, valve gates, and replaceable steel types (P20 for ABS, S136 for medical PC) adapt to polymer abrasiveness or heat load. -

Scientific Molding Discipline

By monitoring cavity pressure and adjusting V/P switchover, molders lock in repeatability even when running hygroscopic nylons or shear-sensitive LCPs. -

Post-Mold Value Chain

Injection parts accept over-molding, in-mold decoration, painting, plating, laser marking, and even secondary machining—broadening material choice without sacrificing cosmetic quality.

4 Simple Material-Selection Framework

| Step | Key Question | Tool |

|---|---|---|

| 1 | Function – Load, wear, temperature? | Property charts, stress simulations |

| 2 | Environment – UV, chemicals, sterilization? | Chemical-compatibility tables |

| 3 | Regulations – UL 94, ISO 10993, FDA? | Supplier data sheets, certification database |

| 4 | Aesthetics & Feel – Gloss, matte, soft-touch? | Mold-texture samples; paint/IMD trials |

| 5 | Cost & Sustainability – Target BOM, eco goals? | TCO calculators, PCR content availability |

5 Live Example: Upgrading a Smart-Home Gear Train

| Metric | Original ABS Gear | Upgraded 30 % GF POM-PTFE Gear |

|---|---|---|

| Gear Noise @4000 rpm | 68 dB | 58 dB |

| Wear After 500 h | 0.22 mm lash | 0.04 mm |

| Resin Cost Δ | +35 % | — |

| Overall Unit Cost Δ* | +7 % | — |

| Warranty Claims Forecast | 2.1 % | 0.4 % |

*Higher resin cost offset by elimination of grease and longer life.

6 How TaiwanMoldMaker.com Accelerates Material Decisions

-

On-Demand Samples – Over 600 commodity, engineering, and specialty grades stocked locally—T1 parts in as little as 5 days.

-

DFM + Moldflow in 48 h – Material-specific gating, cooling, and warp prediction.

-

Bridge-to-Scale Credits – Prototype tools (Al or P20) credited toward production-steel versions after material confirmation.

-

Regulatory Support – ISO 10993 summaries, UL yellow-card integration, and RoHS/REACH dossiers delivered with each quote.

7 Action Plan—Match Material to Performance Without Guesswork

-

Upload CAD & Performance Targets to TaiwanMoldMaker.com.

-

Receive Side-by-Side Material Matrix (price, modulus, UL rating, recyclate %) within 48 h.

-

Approve Prototype Tool & Resin for real-world trials.

-

Validate Process Window using cavity-pressure sensors and DOE.

-

Scale Confidently knowing your polymer choice aligns with cost, compliance, and customer expectations.

Key Takeaways

-

Injection molding supports the broadest polymer selection of any volume process—leverage it.

-

Fillers and additives tailor strength, friction, heat, and compliance without changing tooling.

-

A structured selection framework plus rapid sampling avoids costly mid-program resin swaps.

-

TaiwanMoldMaker.com brings materials, tooling, and process expertise together—so you can ship high-performance parts to market sooner.