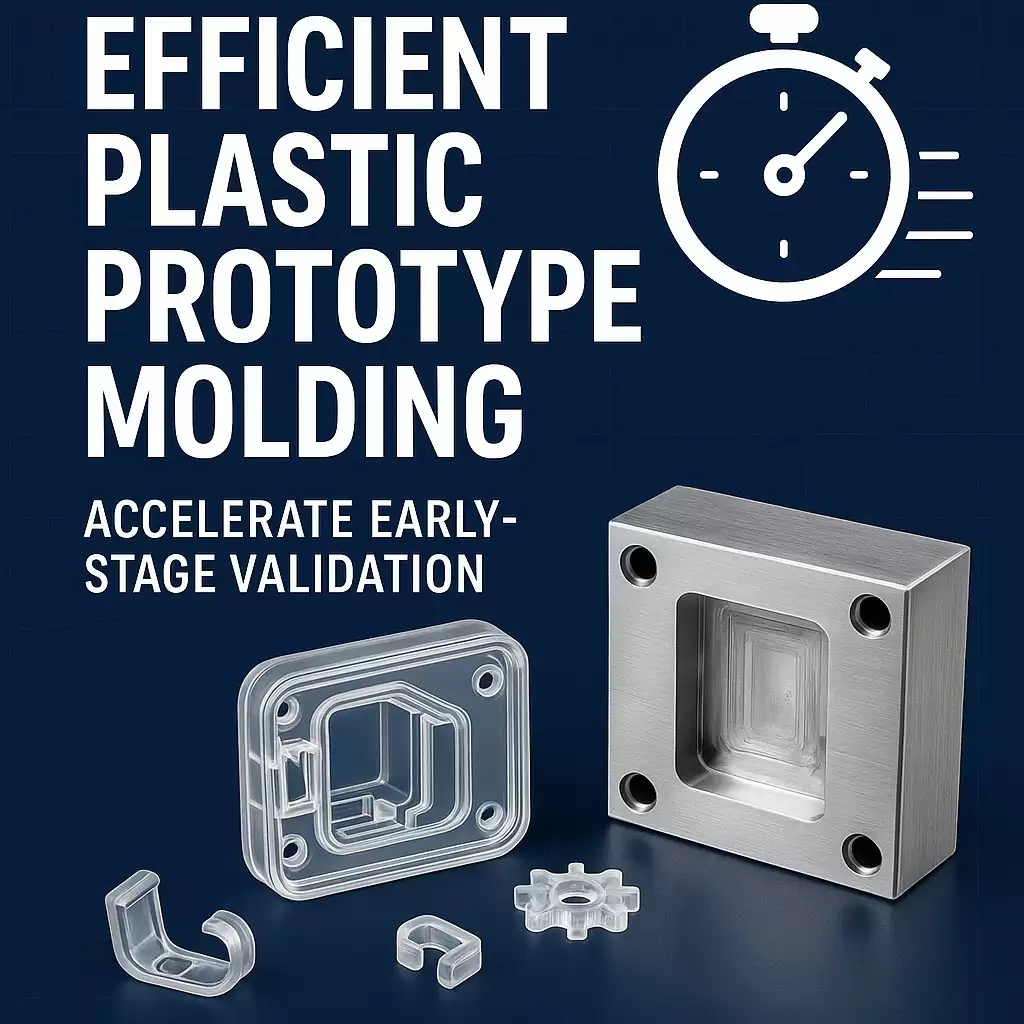

Improve Efficiency in Plastic-Molding Prototype Making for Early-Stage Validation

Improve Efficiency in Plastic-Molding Prototype Making for Early-Stage Validation

Moving from a CAD concept to a test-ready physical part is often the slowest—and costliest—phase of product development. Below is a proven playbook to accelerate plastic-molding prototypes, lock critical-to-quality (CTQ) dimensions earlier, and walk into design reviews with hard data instead of hopeful drawings.

1 Start with a Digital Twin, Not a Quote Request

-

AI-Driven DFM Analysis

Import STEP or native files into a cloud DFM engine to flag draft, undercuts, thin walls, and injection-gate constraints within minutes. -

Virtual Moldflow & Warpage Simulation

Predict weld lines, flow hesitation, and shrinkage deltas before steel is cut—saving one or two tool iterations. -

Tolerance Stack-Up in CAD

Use PMI (Product Manufacturing Information) annotations to identify ±0.02 mm features; relax non-functional tolerances to reduce tool complexity.

Result: 15-30 % design changes happen before money touches steel.

2 Choose the Right Prototyping Path

| Prototype Method | Lead Time | Best For | TaiwanMoldMaker.com Service Link |

|---|---|---|---|

| CNC Machined Plastic | 3-5 days | Very small volumes, drop-test proof-of-concept | Custom Mold and Design Maker |

| Aluminum Bridge Mold | 10-15 days | 50–5 000 shots, design-validation testing | Mold Service |

| SLM/3DP Conformal-Cooled Tool Inserts | 2-3 weeks | Optical parts, thin walls, cycle-time trials | Injection Mold |

| Rapid LSR/Silicone Mold | 12-18 days | Baby-care, medical-grade soft seals | Liquid Silicone Rubber Mold |

3 Build “Learning Loops” into Every Prototype Run

-

Sensor-Based Process Windows

Embed cavity-pressure transducers in bridge tools; export data to Excel or MES so each shot is tagged to CTQ measurements. -

Mini-DOE at T-0

Change one variable at a time—pack/hold, mold temperature, or cooling time—across eight shots; nail CpK ≥ 1.33 within the first eight-hour shift. -

High-Speed 3D Scanning

Scan first articles within 30 minutes of ejection; overlay heat maps against CAD to validate shrink assumptions. -

Rolling Design Handoff

Feed measurement deltas back to the design team that night; release ECNs before the next tool steal.

4 Integrate Secondary Operations Up Front

| Secondary Step | Why Early Integration Saves Time |

|---|---|

| Ultrasonic Welding Ribs | Confirm joint strength during EVT instead of waiting for DVT. |

| Pad-Print & Laser Mark | Check color fastness, contrast, and abrasion resistance on the true resin surface. |

| Inline Leak or Torque Testing | Catch seal failures while fixture costs are still low. |

Co-locating finishing cells next to the prototype press eliminates days of cross-shop logistics and keeps your validation schedule intact.

5 Case Study – Handheld IoT Sensor Housing

| Metric | Conventional Path | Efficient Prototype Path |

|---|---|---|

| Tool Lead Time | 5 weeks (steel) | 12 days (Al 7075) |

| First-Article Pass Rate | 56 % | 93 % |

| Design Changes | 3 ECO rounds | 1 ECO |

| EVT-to-DVT Duration | 14 weeks | 6 weeks |

The start-up saved US $22 000 in tooling rework and hit a trade-show demo date that secured Series-A funding.

6 How TaiwanMoldMaker.com Compresses the Clock

-

48-Hour Prototype DFM Pack – gating, draft, cooling, costed timeline

-

Dual-Path Quotes – bridge tool + production tool in one PDF

-

Press Fleet 60–450 t – tiny wearables to 1 m-long panels

-

Live MES Dashboard – see CpK, OEE, OTIF from your browser

Explore More Solutions:

• Molding – pilot or pre-launch builds

• Silicone Mold – flexible, heat-resistant prototypes

• Metal Stamping – hybrid plastic-metal validation

• Customer Examples – real prototypes that became blockbuster products

7 Next Steps

-

Upload CAD & target volumes (50–5 000 pcs).

-

Schedule a 30-min virtual DFM review—tool layout, resin, and timeline.

-

Approve the bridge-tool quote and receive T-0 parts in as little as two weeks.

Early-stage validation doesn’t have to be the bottleneck. With TaiwanMoldMaker.com you’ll iterate faster, make data-driven design calls, and enter pilot production weeks ahead of competitors. Ready to compress your prototype schedule? Request your no-obligation DFM pack today.