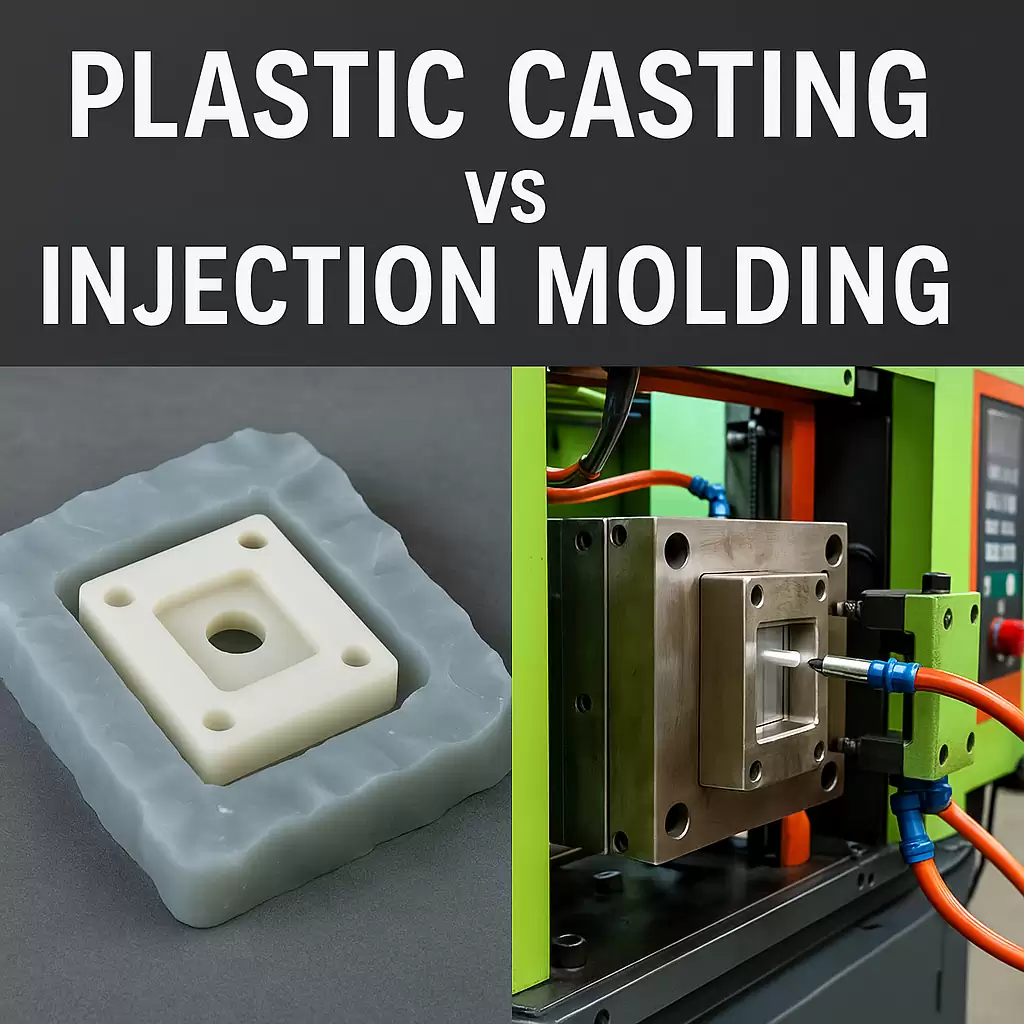

Plastic Casting vs. Injection Molding — How to Choose the Right Process for Your Project

Plastic Casting vs. Injection Molding — How to Choose the Right Process for Your Project

Selecting the best plastic-forming method can spell the difference between a profitable launch and a costly misstep. Two of the most common routes are plastic casting (typically urethane or epoxy resin in silicone molds) and injection molding (thermoplastic pellets melted and injected under pressure into steel or aluminum tools). Although both create polymer parts, they diverge sharply in economics, performance, and scalability. Use the guide below to identify which technology fits your timeline, budget, and quality targets.

1. Process Fundamentals

| Aspect | Plastic Casting | Injection Molding |

|---|---|---|

| Material State | Liquid thermoset or two-part resin cures chemically at ≤ 80 °C | Thermoplastic melt (200 – 300 °C) solidifies by cooling |

| Tooling | Soft silicone, machined aluminum, or 3-D-printed molds | Precision-machined steel or aluminum multi-cavity molds |

| Pressure | Gravity or low vacuum (< 1 bar) | High pressure (500 – 2 000 bar) |

| Cycle Time | Minutes to hours (depends on cure) | Seconds to < 1 min for most parts |

| Thermal Re-Forming | Impossible (thermosets) | Possible; scrap can be re-ground in some cases |

2. Strengths & Limitations

Plastic Casting

Strengths

-

Ultra-low tooling cost (USD $300 – $3 000) — ideal for 1-100 pcs and pilot runs.

-

Complex internal cavities possible with soluble or sacrificial cores.

-

Material flexibility — soft durometer elastomers to optically clear urethanes.

Limitations

-

Slow throughput — cure times lock up molds.

-

Dimensional variation ± 0.3 mm or 0.5 % typical.

-

Surface finish relies heavily on post-processing; paint or clear-coat often needed for UV stability.

Injection Molding

Strengths

-

Scales economically into the millions once tooling is amortized.

-

Tight tolerances & repeatability (± 0.05 mm common).

-

Wide thermoplastic portfolio including glass-fiber, flame-retardant, medical, and food-contact grades.

-

Integrated features — threads, living hinges, overmolds, metal inserts.

Limitations

-

High upfront tooling (USD $10 000 – $100 000+ depending on size/cavities).

-

Design locked early; later changes require costly steel re-cut or new tools.

-

Minimum economic order usually ≥ 1 000 pcs to offset set-up and material start-up scrap.

3. Decision Matrix — Which Process Wins?

| Requirement | Best Fit | Why |

|---|---|---|

| Prototype or 50-piece bridge run | Casting | Fast, inexpensive silicone tools; no long lead time |

| Annual volume > 5 000 pcs | Injection Molding | Lower part cost, automated cycles |

| Wall thickness > 5 mm (no sink risk) | Casting | Thick sections cure without voids |

| Living hinge or snap fit | Injection Molding | Semi-crystalline PP or PE delivers fatigue life |

| Optically clear lenses, 1-3 mm thick | Injection Molding | High-flow PMMA or PC, polishable A-surface |

| Elastomer 20 A shore hardness | Casting | Liquid silicone or PU elastomers without cold-runner waste |

| Regulatory compliance (FDA, ISO 13485) | Injection Molding | Documented process control, lot traceability |

| Large part 600 mm+ with low draft | Casting (RTV) or Structural Foam | Lower clamp tonnage, reduced warp risk |

4. Cost & Lead-Time Snapshot (Single-Cavity Tool, 120 × 80 × 40 mm Part)

| Stage | Casting (Silicone Mold) | Injection Molding (Al Tool) |

|---|---|---|

| Tool Fabrication | 2 – 5 days | 3 – 4 weeks |

| Tool Cost | USD $800 | USD $12 000 |

| Cycle Time / Part | 6 – 10 min | 35 s |

| Piece Price @100 pcs | ~ $18 | ~ $45 |

| Piece Price @10 000 pcs | ~ $14 (multiple molds) | ~ $1.20 |

5. Hybrid Roadmap — Casting Today, Molding Tomorrow

-

Concept Validation — SLA/FFF 3-D-print for fit & feel.

-

Functional Prototype — Urethane casting in silicone to test mechanicals.

-

Bridge Production — Aluminum injection tool (1-2 cavities) for pilot launch.

-

Full Scale — Hardened steel, multi-cavity tool once demand stabilizes.

This phased approach reduces cash burn while ensuring that DFM knowledge migrates smoothly from prototype to mass production.

6. How TaiwanMoldMaker.com Simplifies Your Choice

-

Dual-Capability Network: Access both rapid casting studios and ISO-certified injection molders under one roof.

-

DFM Workshops in 48 hrs: Receive side-by-side cost models and tolerance studies.

-

Bridge-to-Scale Programs: Aluminum tools cut in as little as 10 days, then upgraded to steel when volume soars.

-

Integrated QA: SPC, CMM, and material certification keep regulatory pathways clear.

7. Key Takeaways

-

Casting wins for speed, flexibility, and very low volumes.

-

Injection molding dominates when precision, repeatability, and cost per part rule the P&L.

-

A hybrid pathway—start cast, scale to mold—de-risks investment and preserves time-to-market.

Ready to match the perfect process to your next product? Contact TaiwanMoldMaker.com for a free comparative assessment and turn design intent into manufacturable reality—today and at scale.