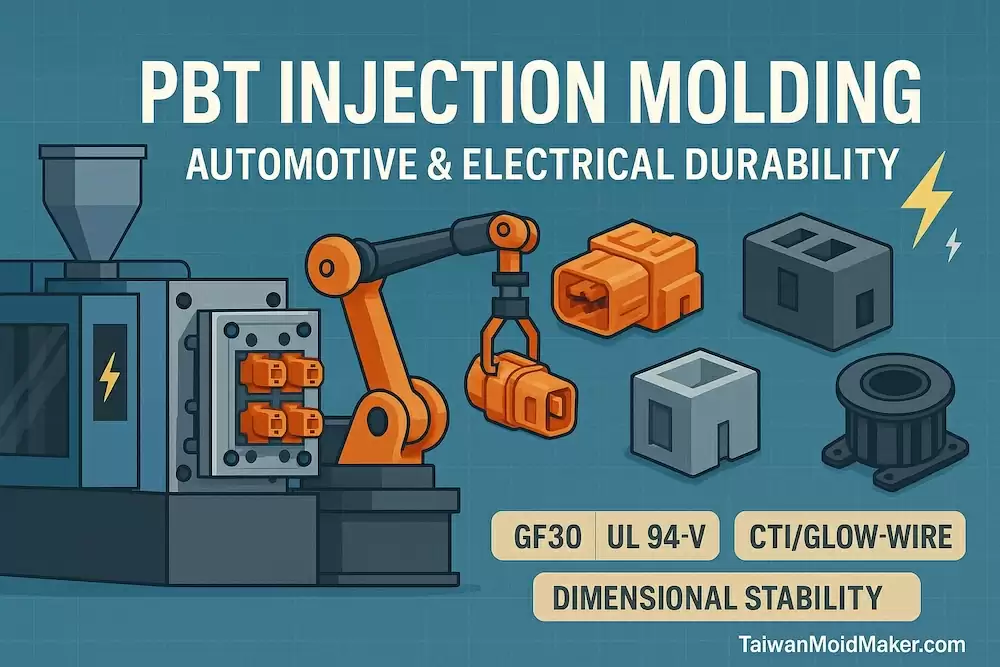

PBT Injection Molding for Automotive & Electrical Component Durability

PBT Injection Molding for Automotive & Electrical Component Durability

Explore PBT Injection Molding for Automotive & Electrical Component Durability

Polybutylene terephthalate (PBT) is a high-crystallinity engineering thermoplastic known for dimensional stability, electrical insulation, chemical resistance, and fast cycles. With the right grade—glass-fiber, flame-retardant, impact-modified—PBT delivers rugged parts for under-hood, powertrain, connectors, relay bases, sensors, motor housings, EV charging components and more.

Why Choose PBT for Auto & E/E?

-

Dimensional stability: low moisture uptake → tight tolerances over time (less drift than PA6/PA66).

-

Electrical performance: high CTI/PLC options, good dielectric strength; FR grades achieve UL 94 V-0 and glow-wire compliance.

-

Heat & creep resistance: withstands continuous service in warm engine bays and live electrical environments.

-

Chemical resistance: fuels, oils, coolants, cleaners; good hydrolysis-resistant grades available.

-

Cosmetics + speed: high crystallinity yields short cooling times and crisp surfaces—great for housings and visible parts.

PBT Grade Map (Pick by Requirement)

| Grade | Typical Use | Key Benefits | Notes |

|---|---|---|---|

| Unfilled PBT | Thin covers, coil bobbins | Fast cycles, nice surface | Lower stiffness than GF grades |

| GF20/30/40% | Brackets, carriers, motor housings | High stiffness/HDT, low creep | Manage fiber orientation to control warp |

| FR (halogen-free or brominated) | Connectors, relay bases, EV components | UL 94 V-0, CTI up to high levels, glow-wire | Slight cycle/flow changes vs non-FR |

| Impact-modified | Clips, snaps, latches | Toughness at low temperatures | Balance vs stiffness |

| PBT/PC or PBT/PET blends | Cosmetic housings needing impact | Surface quality + toughness | Adjust mold temp for best surface |

| Laser-markable / UV-stabilized | Traceable E/E parts, exterior trim | Readability & weathering | Specify color/contrast targets |

High-Value Applications

-

Automotive: sensor & ECU connectors, relay/fuse boxes, fan shrouds, pump/valve housings, gear-motor covers, mirror carriers, lamp sockets, charge-port parts.

-

Electrical/Electronics: terminal blocks, coilformers, switch bodies, circuit breakers, contact carriers, HV orange plug bodies, appliance connectors.

Design Rules That Keep PBT Parts Robust

-

Walls: 1.5–3.0 mm typical; keep uniform to limit sink/read-through.

-

Ribs: 40–60% of adjacent wall; add fillets to diffuse stress.

-

Draft: ≥1.0–1.5° textured; ≥0.5° polished; add more for deep ribs.

-

Bosses: ID ≈ 60–70% OD; fillet bases; tie into walls with ribs.

-

Gates: for GF grades, align flow with load paths; use fan/film on skins to reduce weld visibility.

-

Inserts/metal contacts: design poka-yoke nests; consider pre-heat for bond quality and stress reduction.

-

Creepage/clearance: follow your voltage class—define CTQ distances on drawings.

Processing Window (Typical Starting Points—tune via DOE)

| Parameter | Range* | Notes |

|---|---|---|

| Drying | 120 °C for 2–4 h (≤0.02% moisture) | Moisture causes hydrolysis → brittleness/splay |

| Melt Temp | 240–260 °C (FR blends may vary) | Avoid long residence to prevent degradation |

| Mold Temp | 60–100 °C (80–120 °C for cosmetics/GF) | Higher temps improve surface & crystallinity |

| Injection Speed | Medium–High | Helps knit strength on thin features |

| Pack/Hold | Sufficient to control sink/voids | Beware over-packing at bosses |

| Shrinkage | Unfilled ~1.2–2.0%; GF ~0.2–0.7% | Anisotropic with GF → gate/cool symmetrically |

*Actual settings depend on grade, geometry, and hot-runner choice.

Tooling & Cell Options from Our Network

-

Valve-gated hot runners (natural/engineered balance) for multi-cavity connectivity parts.

-

Conformal-cooled inserts or high-conductivity cores at hot spots → shorter cycles, flatter parts.

-

Inline automation: insert loading, laser mark, vision seam/vestige control, torque/leak tests.

-

MES dashboards: live OEE, CpK at CTQs, genealogy for PPAP or device history records.

Quality & Compliance (Auto + E/E)

-

APQP/PPAP Level 3 readiness (DFMEA/PFMEA, control plan, MSA, capability).

-

Electrical: CTI/PLC targets, Glow-Wire (GWIT/GWFI), RTI as required.

-

Material: RoHS/REACH, halogen-free options, HV orange color control for EV standards.

-

Metrology: FAIR + CMM/blue-light scans; custom fixtures for warpage & pin dimensions.

-

Cosmetics: ΔE color thresholds, gloss/orange-peel mapping under defined lighting.

PBT vs. Alternatives (Quick Buyer’s View)

| Attribute | PBT | PA66 | POM | PC/ABS |

|---|---|---|---|---|

| Moisture uptake | Low (stable dims) | High (pre-dry; dims drift) | Very low | Low–Med |

| Electrical insulation/CTI | Excellent | Good | Good | Good |

| Chemical/oil resistance | High | Med–High | Very High | Med |

| Heat resistance (HDT) | High (↑ with GF) | High | Med | Med |

| Surface/cycle speed | Fast, crisp | Med | Med | Med |

| Toughness (unfilled) | Med | Med–High | Med | High |

Typical Outcomes from Optimized PBT Cells

| KPI | Before (Generic Cell) | Optimized PBT Cell |

|---|---|---|

| Cycle (GF30 connector body) | 18.5 s | 14.5–15.8 s |

| Warpage (70 mm housing) | 0.35 mm | ≤0.18–0.22 mm |

| Cosmetic rejects | 2–3% | ≤1% |

| CpK at pin-to-pin (CTQ) | 1.33 | ≥1.67 |

Representative; results depend on resin and geometry.

RFQ Template (Copy/Paste)

Subject: RFQ – PBT Injection Molding (Automotive/Electrical)

Attachments: STEP/IGES + 2D drawing with CTQs and creepage/clearance

-

Part name / revision:

-

Annual volume & first PO qty:

-

PBT grade targets: (GF %, FR/halogen-free, CTI/PLC, glow-wire, UV, color—e.g., HV orange)

-

Dimensional hotspots & tolerance bands (pin-to-pin, flatness/warp):

-

Cosmetic class & texture: (A/B/C, SPI code, ΔE tolerance)

-

Special features: (inserts, overmold, laser-mark window)

-

Inspection pack: (FAIR, CMM, electrical tests, PPAP level)

-

Packaging/logistics: (returnable trays, label spec, EDI/ASN)

-

Target dates (T0/T1/PPAP/SOP) & Incoterms:

-

Known risks (thin walls, long flow, weld areas):

Related Services & Quick Links

-

Custom Mold & Design Maker – DFM & CAE for PBT gating/cooling

https://www.taiwanmoldmaker.com/product/custom-mold -

Mold Service – aluminum, hybrid, and full steel tooling

https://www.taiwanmoldmaker.com/product/mold-service -

Injection Mold – materials & processes overview

https://www.taiwanmoldmaker.com/product/injection-mold -

Molding – automated cells with MES traceability

https://www.taiwanmoldmaker.com/product/molding -

Customer Examples – case snapshots and results

https://www.taiwanmoldmaker.com/product/customer-examples

Call to Action

Building durable automotive or electrical parts that must pass CTI/glow-wire and stay dimensionally true? Send CAD and requirements to receive a 48-Hour DFM & Cost Pack with gating plan, cooling concept, and qualification path.

Request an Instant Quote → https://www.taiwanmoldmaker.com/contact