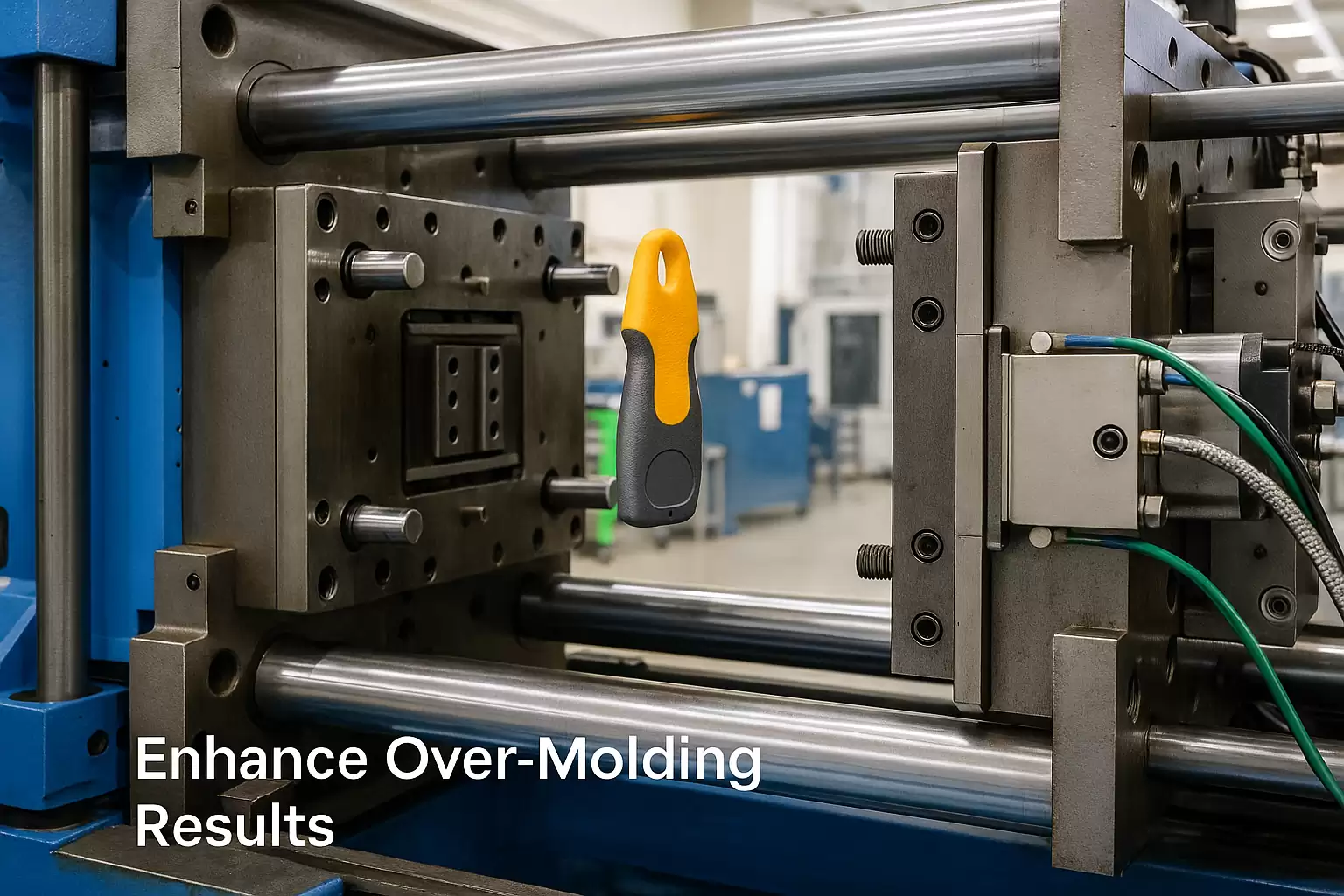

Enhance Over‑Molding Results with Expert Overmolding Injection Molding Processes

Enhance Over‑Molding Results with Expert Overmolding Injection Molding Processes

Over‑molding—also called two‑shot or insert molding—allows manufacturers to fuse two or more materials into a single, fully integrated component. From soft‑touch grips on power‑tool housings to hermetically sealed electronics, over‑molding delivers performance and aesthetics that single‑material parts simply can’t match. Achieving flawless adhesion, dimensional stability, and cycle efficiency, however, demands specialized tooling, process controls, and material know‑how. Below, we outline best practices for world‑class overmolding injection molding and explain how INTERTECH (https://www.taiwanmoldmaker.com) turns complex multi‑material concepts into production‑ready realities.

1 Why Over‑Molding?

| Benefit | Real‑World Impact |

|---|---|

| Integrated Soft Grip | Ergonomic handles for power tools, toothbrushes, medical devices |

| Sealed Electronics | IP‑rated sensor housings without secondary gasketing |

| Vibration Damping | Rubber‑over‑plastic inserts in automotive clips and mounts |

| Colour & Branding | In‑mold logos or contrasting accents—no post‑painting needed |

| Assembly Reduction | Multi‑shot parts cut screws, adhesives, and labor from the BOM |

2 Key Process Variants

-

Two‑Shot (Rotary or Transfer)

Two different polymers injected sequentially in a single press cycle—ideal for high volumes. -

Insert Over‑Molding

Pre‑formed metal or plastic inserts placed into the cavity, then encapsulated—good for electronics or threaded inserts. -

Multi‑K Rotary Stack Molding

Rotating platen alternates cavities for three or more materials, maximizing cavitation and colour choices.

3 Material Selection & Adhesion

-

TPE → PP / ABS / PC blends for soft‑touch zones.

-

PA → GF PP hybrid structures for under‑hood brackets (chemical bonding + mechanical interlock).

-

LCP → Copper Inserts for high‑frequency antenna over‑molding.

INTERTECH collaborates with global compounders (e.g., Avient™, RTP, Sabic™) to source adhesion‑optimized grades and provides peel‑test validation per ASTM D903.

4 Tooling & Design Considerations

| Parameter | Best Practice |

|---|---|

| Draft | 1–2° on substrate, 3–4° on elastomer to aid release |

| Undercuts / Mechanical Keys | Add ribs, holes, or dovetails when chemical adhesion alone is insufficient |

| Gate Placement | Direct gating on over‑mold avoids knit lines and voids |

| Cooling | Conformal channels balance core & cavity temps across materials |

| Shut‑Off Angles | Precision ground 3–5° shut‑offs prevent flash between shots |

5 Process Control Essentials

-

Mold‑flow Simulation (2K Modules) – Predict interface bonding, temperature gradients.

-

Sequential Valve Gating – Controls second‑shot flow to eliminate air entrapment.

-

Real‑Time Pressure Sensors – Monitor cavity pressure for consistent adhesion.

-

Robot/Cobots for Insert Loading – Maintains cycle time and positional accuracy.

6 Typical Industries & Applications

-

Consumer Electronics – Soft TPU bumpers over PC/ABS phone cases.

-

Medical Devices – TPE seals over transparent PC barrel for autoinjectors.

-

Automotive – Nylon brackets over‑molded onto metal bus bars for weight reduction.

-

Power Tools & Industrial – Dual‑material grips; vibration‑dampening feet.

7 INTERTECH’s Over‑Molding Expertise

-

Rotary two‑shot presses up to 350 t with servo index.

-

Vertical insert molding for metal/plastic hybrid parts.

-

In‑house DFM + 2K mold design—CAM, EDM, and laser‑textured shut‑offs.

-

ISO 9001, ISO 13485, and automotive PPAP documentation.

-

Cleanroom molding available for medical multi‑material components.

Explore case studies on our custom molding page or request a design review.

Conclusion

Expert‑level overmolding injection molding processes unlock superior ergonomics, durability, and production efficiency—critical differentiators in competitive markets. By partnering with INTERTECH, you tap into decades of multi‑material tooling know‑how, advanced machinery, and robust quality systems that ensure every over‑molded part performs as intended.

Ready to enhance your product with over‑molding? Contact INTERTECH for a free feasibility and adhesion consultation.