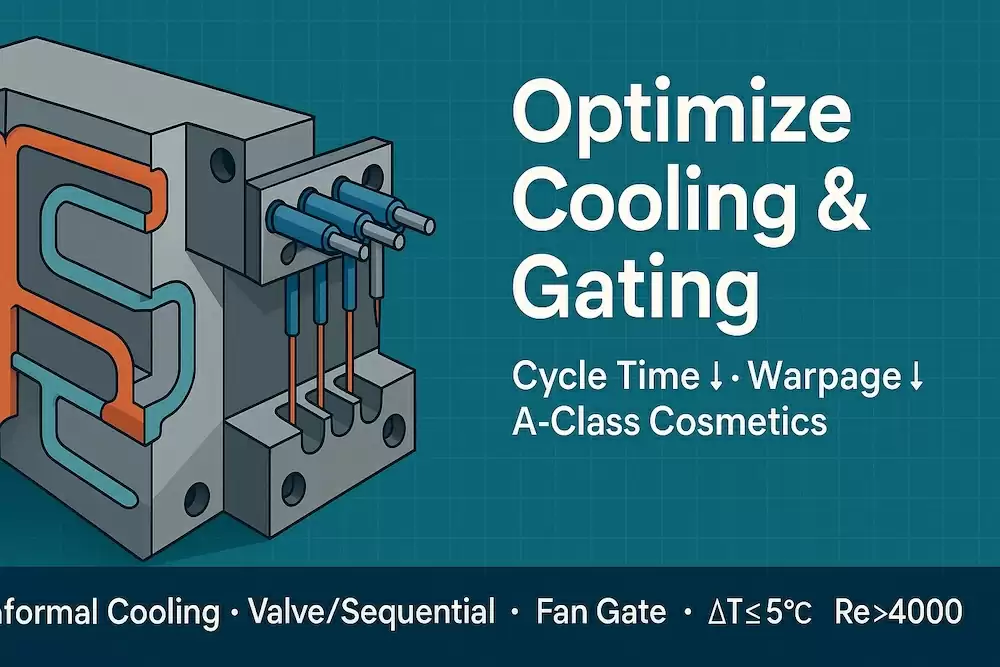

Optimize Injection Mold Tooling with Refined Cooling Channels & Gating

Optimize Injection Mold Tooling with Refined Cooling Channels & Gating

Optimize Plastic Injection Mold Tooling with Refined Cooling Channels and Gating

In injection molding, most of the cycle is cooling—and most visual/structural defects trace back to gating. Refining these two elements delivers outsized wins: shorter cycle times, lower warp, stronger knit lines, and stable CpK at critical-to-quality (CTQ) features. The TaiwanMoldMaker.com partner network co-engineers cooling and gating from Day 1, pairing simulation with scientific molding to lock a robust window.

Why Cooling & Gating Matter (In One Graphic)

-

Cooling: controls cycle time, shrink/warp, residual stress, gloss

-

Gating: controls fill balance, shear/temperature history, weld lines, gate vestige/cosmetics

Treat them as a coupled system: wrong gate → uneven fill → uneven packing → uneven cooling.

Cooling Design: Practical Rules That Move the Needle

Targets (typical starting points, adjusted per resin & geometry):

-

Channel Ø 8–12 mm for medium molds; larger plates scale up.

-

Channel depth: ~1–1.5× channel Ø from cavity surface.

-

Pitch/spacing: 2–3× channel Ø between lines.

-

Coolant ΔT loop in/out: keep within 2–5 °C across circuits.

-

Aim for turbulent flow (Reynolds > 4,000) to maximize heat transfer.

-

Balance circuits in parallel (not long serial snakes) to equalize temperature.

-

Use manifolds with similar line lengths to minimize pressure drop variations.

-

Filtration (100–200 µm) + water treatment prevents fouling and scale.

Tooling options & where they shine

| Cooling Method | Best For | Advantages | Notes |

|---|---|---|---|

| Drilled straight lines (baffles/bubblers) | General parts | Fast, economical | Add baffles near cores; avoid dead zones |

| Conformal cooling (AM/3D inserts) | Deep cores, thick/heatsinks, optics | Uniform skin temps, big cycle cuts | Great for PP/PA warpage control; plan spare inserts |

| High-conductivity inserts (Cu alloys) | Hot spots, ribs/boss clusters | Pulls heat rapidly | Coat/wear-protect as needed |

| Thermal pins/heat pipes | Localized deep cores | Passive hot-spot removal | Size for power; ensure good seating |

| Oil temp control | PC/ABS gloss, RHCM | Surface quality, reduced stress | Higher temps; seal & safety discipline |

Verification tools

-

Mold thermal simulation (CAE), IR camera on first trials, cavity thermocouples, and ΔT gauges on manifolds.

Gating Strategy: Put Flow & Cosmetics Under Your Control

Gate style selection (quick matrix)

| Gate Type | Best For | Key Benefits | Watch-outs |

|---|---|---|---|

| Edge/Tab | General parts, easy access | Simple, robust packing | Vestige, flow marks on A-side if mis-placed |

| Sub/Tunnel | Auto-de-gate small/medium parts | No secondary trim | Shear/heat on viscous resins; tool wear |

| Pin/Direct | Small round footprints | Compact vestige | Gate blush on clear/PC if too hot |

| Fan/Film | Large skins, thin walls | Low shear, weld control | More steel real estate |

| Diaphragm | Cylindrical/round parts | Central, even fill | Trim/vestige planning |

| Hot Tip | Small cosmetic gates | Reduced freeze, small vestige | Shear/gloss halos on some resins |

| Valve Gate | Multi-cavity caps, A-class parts | On/off control, no stringing | Cost/controls; pin witness management |

| Sequential Valve (Cascade) | Long flow paths/panels | Moves weld line off-view | Tight timing + sensor feedback |

Sizing and placement tips

-

Size for allowable shear (avoid splay/burn) and enough pack to control sink.

-

Keep gate land short (≈0.8–1.2 mm typical) to reduce freeze-off sensitivity.

-

Direct flow so weld lines land in non-cosmetic, low-stress zones.

-

On GF materials, align gates with load paths to manage fiber orientation/warp.

-

For clear PC/PMMA, consider hot tip + higher mold temps or RHCM to hide welds.

Rule-of-thumb reminders (for first sizing; finalize via DOE)

• Rectangular gate shear rate — keep within the resin’s window.

• Gate freeze time correlates with thickness²—thin gates freeze fast, starving pack.

Cooling × Gating: A Coupled DOE

-

Simulate fill/pack/cool to predict knit lines, pressure drop, hot spots.

-

Build with instrumentation (cavity pressure & thermocouples at critical zones).

-

DOE variables: gate temperature, open/close timing (valve), pack profile, mold temp, coolant flow/ΔT.

-

Lock golden recipe at the press: V/P transfer by cavity pressure, not just screw position.

-

SPC: monitor cycle, cavity ΔP, ΔT, and gate freeze time proxies; alarm on drift.

Typical Improvements From Refined Cooling & Gating

| KPI | Before (Conventional) | After (Refined) |

|---|---|---|

| Cycle (thin-wall ABS housing) | 28–30 s | 21–24 s |

| Warpage (150 mm PP panel) | 0.7–0.9 mm | ≤0.3–0.4 mm |

| Sink defects at bosses | Visible | Non-detectable at 50 cm |

| Cosmetic rejects | 2–4% | ≤1% |

Actuals vary by geometry, resin, and tool; these are representative.

What We Deliver (TaiwanMoldMaker.com Network)

-

48-Hour DFM Pack: gate/cooling layout, risk map, and cycle model

-

Hot runner strategy: valve/sequential with natural or engineered balance

-

Conformal-cooled inserts and high-conductivity steels where they pay back

-

Scientific molding DOE with cavity-pressure curves; recipe guardrails in MES

-

Metrology first: blue-light/CMM on CTQs, color ΔE/gloss for A-class, warpage fixtures

-

Sector quality: ISO 9001 network; IATF 16949 / ISO 13485 available at partner plants

Design Cheatsheet (Copy/Paste)

-

Walls uniform; ribs at 40–60% of wall; core heavy bosses.

-

Draft ≥1.0–1.5° textured; ≥0.5° polished; more on deep ribs.

-

Gate away from A-class; use fan/film on large skins; sequential valves for long flow.

-

Cooling circuits parallel & balanced; ΔT ≤5 °C; keep Re > 4,000.

-

Instrument at least one cavity with pressure + temp for scalable learning.

RFQ Template (Cooling & Gating Emphasis)

Subject: RFQ – Optimized Cooling & Gating (Injection Mold Tooling)

Attachments: STEP/IGES + 2D with CTQs & cosmetic map

-

Part name / revision:

-

Resin & color (grade/MFR, fills, FR/UV):

-

Cosmetic class & texture codes:

-

Priorities: (cycle ↓, warp ↓, A-class gloss, weld-line strength, etc.)

-

Preferred gate style(s) and keep-outs:

-

Cooling constraints: (press water temp/pressure, chiller capacity, oil requirement)

-

Measurement pack: (FAIR, CMM, warpage fixture, ΔE/gloss, cavity pressure curves)

-

Quantities & target dates (T0/T1/PPAP/SOP):

-

Logistics: (dual-plant, call-off, export labels)

Related Services & Quick Links

-

Custom Mold & Design Maker – DFM & CAE for gating/cooling

https://www.taiwanmoldmaker.com/product/custom-mold -

Mold Service – aluminum, hybrid, and full steel tooling

https://www.taiwanmoldmaker.com/product/mold-service -

Injection Mold – materials & processes overview

https://www.taiwanmoldmaker.com/product/injection-mold -

Molding – automated cells with valve gates & MES traceability

https://www.taiwanmoldmaker.com/product/molding -

Customer Examples – snapshots and results

https://www.taiwanmoldmaker.com/product/customer-examples

Call to Action

Want faster cycles and flatter parts without cosmetic trade-offs? Share your CAD and CTQs to receive a 48-Hour DFM & Cost Pack: gating map, cooling plan, cycle model, and qualification timeline.

Request an Instant Quote → https://www.taiwanmoldmaker.com/contact