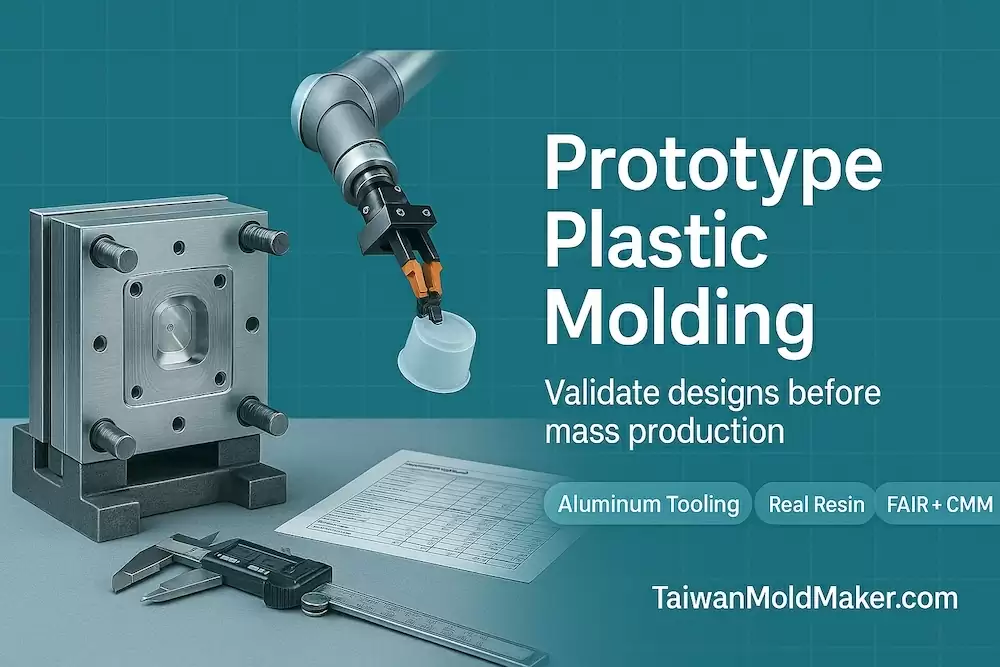

Validate New Designs with Prototype Plastic Before Mass Production

Validate New Designs with Prototype Plastic Before Mass Production

Validate New Designs with Prototype Plastic Before Committing to Mass Production

Bold ideas deserve real proof—in the actual resin, with proper gates, cooling, and repeatable cycles. Prototype plastic molding lets you test fit, function, cosmetics, and manufacturing risk before you invest in multi-cavity steel. The TaiwanMoldMaker.com partner network builds quick-turn tools and runs scientific trials so you can make a confident go/no-go call, then scale smoothly.

Why Prototype in Real Plastic (Not Just 3D Prints)

-

Material-true behavior: impact, creep, fatigue, chemical/UV resistance in the production resin (PP, PC/ABS, PA-GF, POM, PETG, TPE, etc.).

-

Assembly realism: snap-fits, living hinges, screws, welds, inserts, and overmold bonds behave like they will in series production.

-

Cosmetics under control: gate vestige, weld-line visibility, gloss/texture, color ΔE checked on the molded surface.

-

Process knowledge: pack/hold, V/P transfer, cooling balance, and cycle time data for the future golden recipe.

-

Risk reduction: find the fail points while the tool is still easy (and cheap) to modify.

Prototype Tooling Options (Pick for Purpose)

| Option | Typical Qty Range* | Lead Time* | Where It Shines | Notes |

|---|---|---|---|---|

| Aluminum single-cavity | 30–2,000 | 7–15 days | Most parts; EVT/DVT | Fastest path to real resin; re-cut friendly |

| Hybrid soft tool (Al + steel inserts) | 200–5,000 | 10–20 days | Glass-filled/abrasive resins; local wear | Steel on gates/ribs/edges; extends shot life |

| Modular base + swap inserts | 50–1,000/insert | 7–15 days/insert | Variants (logos, ports, features) | Economical A/B/C revisions |

| 3D-printed inserts (SLA/metal) | 10–200 | 5–10 days | Gate trials, subtle geometry changes | Use for quick learning, not long runs |

| Urethane casting (silicone mold) | 10–50/mold | 5–10 days | Cosmetic housings, demo builds | Not material-true for structural tests |

*Actuals depend on geometry, resin, surface class, and inspection pack.

What You Can Prove—Before Steel

-

Fit & assembly: snap-fit force, screw boss torque/pull-out, flushness, tolerance stack-ups

-

Function: hinge life, latch strength, gear mesh (POM), low-friction sliding, seal compression set (TPE/TPV)

-

Environment: thermal cycle (e.g., -20~60 °C), humidity soak, chemical splash (cleaners, oils, fuels), UV stability

-

Cosmetics: weld-line visibility, gate vestige, sink/read-through, color ΔE, gloss/orange peel

-

Process: cycle time, cooling ΔT, warpage, fiber orientation effects (PA-GF/PBT-GF)

Prototype → Production: A Practical Workflow

-

Upload CAD & targets (NDA-protected): required tests, resin/color, quantity, deadline.

-

48-Hour DFM & Cost Pack: gate/cooling plan, risk map, cycle model, and inspection scope.

-

Quick-turn tool build (aluminum or hybrid) with texture/polish as specified.

-

T0/T1 trials (scientific molding): cavity-pressure curves set V/P transfer; IR/thermocouples verify cooling balance.

-

First-Article submission (FAIR): CMM/blue-light scan, ΔE/gloss, functional checks.

-

Pilot run / field trial: short batch under guarded recipe with full traceability.

-

Iterate & freeze: minor re-cuts or insert swaps → copy-cavity to steel when ready.

Design Rules That Speed Prototyping (and Lower Risk)

-

Uniform walls with ribs at 40–60% of wall; core heavy bosses.

-

Draft: ≥1.0–1.5° textured; ≥0.5° polished; add more on deep ribs/cores.

-

Bosses: ID ≈ 60–70% OD; fillet bases; tie into walls with ribs.

-

Gates: off A-class faces; fan/film for skins; valve gates for cosmetics or high-cavity parts.

-

Living hinges (PP): hinge 0.25–0.50 mm, flow across hinge; radius generously.

-

Overmolds: specify substrate grade + TPE chemistry; define peel/shear targets; plan seam-vision control.

Test Plan—Right Sized for Prototypes

Metrology: FAIR + CMM/blue-light, GR&R on CTQs

Functional: snap cycles, torque, hinge life, clip retention, gear wear

Environmental: thermal cycle, humidity, chemical splash/soak, UV exposure

Cosmetics: ΔE color, gloss, weld-line/kiss-off mapping under defined lighting

Process Capability: document golden recipe; capture cavity pressure, cycle time, and gate freeze behavior

Prototype vs. Alternatives (Quick Comparison)

| Requirement | Prototype Injection Molding | 3D Printing | CNC from Plate |

|---|---|---|---|

| Real-resin properties | Yes | Partial | Yes (if stock available) |

| True molded cosmetics | Yes | No | No |

| Assembly feature realism | High | Medium | Medium |

| Lead time (first parts) | Fast | Fastest | Medium |

| Cost (1–200 pcs) | Medium | Low–Medium | High |

| Scale to bridge/series | Easy | Limited | Limited |

What We Deliver (TaiwanMoldMaker.com Network)

-

Quick-turn tools (aluminum/hybrid) for 1–2,000+ prototype parts

-

Scientific trials with cavity-pressure/V/P control and documented parameters

-

Metrology first: FAIR, CMM/scan, GR&R on CTQs; ΔE/gloss for A-class

-

Material coverage: PP/PC-ABS/ABS/PA(±GF)/POM/PETG/TPE/TPV and more

-

Traceability: lot genealogy and recipe guardrails in MES

-

Scale path: bridge-to-steel credits and copy-cavity to multi-cavity production

RFQ Template (Copy/Paste)

Subject: RFQ – Prototype Plastic Molding (Design Validation)

Attachments: STEP/IGES + 2D with CTQs & cosmetic map

-

Part name / revision:

-

Quantity & target ship date: (e.g., 80 pcs in 12–15 days)

-

Resin & color: (grade/MFR if known; FR/UV/food-contact?)

-

Tests to pass: (snap fatigue, torque, chemical splash, ΔE/gloss, warpage, etc.)

-

Surface class & texture: (A/B/C, SPI code)

-

Special features: (living hinge, inserts, overmold, threads)

-

Inspection pack: (FAIR, CMM/scan, ΔE/gloss, capability)

-

Packaging/logistics: (kits per station, export labels)

-

Destination & Incoterms:

Related Services & Quick Links

-

Custom Mold & Design Maker – DFM and prototype tooling

https://www.taiwanmoldmaker.com/product/custom-mold -

Mold Service – aluminum, hybrid, and full steel tooling

https://www.taiwanmoldmaker.com/product/mold-service -

Injection Mold – materials & processes overview

https://www.taiwanmoldmaker.com/product/injection-mold -

Molding – pilot to bridge runs with MES traceability

https://www.taiwanmoldmaker.com/product/molding -

Customer Examples – case snapshots and results

https://www.taiwanmoldmaker.com/product/customer-examples

Call to Action

Ready to validate your design in real plastic before you commit to mass production? Send CAD and test priorities to get a 48-Hour DFM & Cost Pack with the gating plan, cycle model, and test schedule.

Request an Instant Quote → https://www.taiwanmoldmaker.com/contact