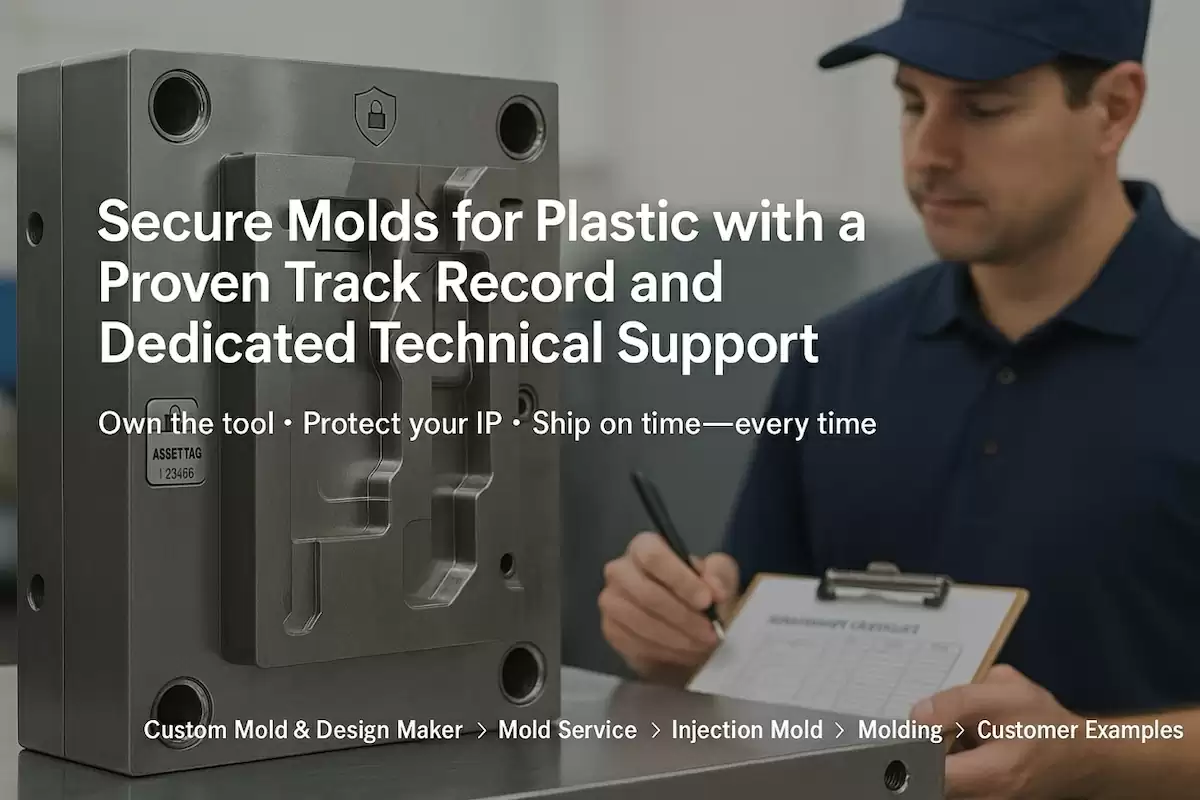

Secure Molds for Plastic with a Proven Track Record and Dedicated Technical Support

Secure Molds for Plastic with a Proven Track Record and Dedicated Technical Support

Secure Molds for Plastic with a Proven Track Record and Dedicated Technical Support

Own the tool • Protect your IP • Ship on time—every time

When your program depends on reliable, repeatable plastic parts, the first decision is the most strategic one: who builds and secures your molds—and who stands behind them after SOP. With the TaiwanMoldMaker.com network, you don’t just buy a tool; you gain a documented performance history, a clear maintenance plan, and a dedicated technical support team from DFM to end-of-life.

Explore our end-to-end services:

Custom Mold & Design Maker → Mold Service → Injection Mold → Molding → Customer Examples → Contact

What “secure molds” really means

-

Tool ownership & custody: Contracted customer ownership, serialized asset tags, controlled storage, insured transit.

-

IP protection: NDA + restricted repo access for CAD/NC files; watermarking on exports; vendor white-labeling on tool nameplates by request.

-

Preventive maintenance (PM): Shot-based PM intervals, grease/lube consumables, hot-runner health checks, cavity balance verification, and a spare-parts kit included (springs, pins, heaters, thermocouples, seals).

-

Disaster readiness: Off-site backups of CAD/tool data and copy-cavity plans so capacity can be recovered quickly if needed.

“Proven track record”: what you can verify

We define track record with data you can audit:

-

OTIF (On-Time, In-Full) delivery history and launch adherence vs. Gantt.

-

First-pass yield at T0/T1 and ramp CpK on CTQs.

-

Tool uptime and OEE by job, including scrap and rework trends.

-

Supplier references & part families similar to your geometry/resin/regulatory profile.

Ask us for a redacted MES dashboard link during quoting—see OEE, CpK, scrap, and even kWh/kg from representative cells.

Dedicated technical support—your single accountable owner

-

One program owner from DFM → T0 → PPAP/IQ-OQ-PQ → SOP.

-

Response SLAs: same-day triage (<4 hrs), corrective action plan (<24 hrs), engineering changes scheduled within 48–72 hrs.

-

Remote eyes: live cell cameras during trials; shared metrology and DOE workbooks; weekly cadence calls with action logs.

-

On-site options: Tooling engineer travel for buy-offs, line trials, and root-cause workshops.

How we build molds that last (and run fast)

-

Design rules: Uniform walls, balanced runners, venting strategy, thermal analysis (cooling line layout, baffle/bubbler, conformal-cooling candidates).

-

Steel & coatings: H13 / S136 / 420SS with nitriding or DLC/TiN where needed; certified steel heat-treat records with hardness readings.

-

Hot halves: Valve-gated systems for cosmetics/vestige control; manifold brand and spares documented.

-

Sensors & control: Cavity pressure sensors, V/P by pressure, mold-temp loop control, and gate-freeze studies during trials.

-

Maintainability: Standard hardware, pull-plate service access, doweled sub-inserts for high-wear features, and engraved part numbers on replaceables.

Documentation you receive with every tool

-

Tooling Dossier: 3D/2D tool drawings, BOM, steel certs, heat-treat, hot-runner manuals, torque map, cooling diagram.

-

Trial Pack: T0/T1 parameter sheets, weight ladder, gate-freeze curves, cavity balance, DOE matrix and results.

-

Metrology Pack: FAIR + CMM/scan reports, GR&R, cosmetic map with ΔE/gloss if applicable.

-

Maintenance Plan: PM intervals by shots/time, consumables list, spares, and inspection checklist.

-

Change Log: ECN/ECR history with dated redlines and risk assessments.

Acceptance criteria (how we sign off together)

-

Dry run: Mold opens/closes/ejects reliably ≥200 cycles; safety interlocks verified.

-

Process window: DOE defines nominal and high/low bounds; alarms/lockouts set on press and logged in MES.

-

Dimensional & cosmetic: CTQs meet spec with CpK ≥ 1.33 (or per contract); cosmetic classes signed against the map.

-

Rate readiness: Cell proves target cycle time at pilot cavitation; if family/multi-cavity, balance is within tolerance.

-

Pack-out: Packaging, labeling, and pallet patterns validated for FA and mass production.

Example timeline (prototype → SOP)

-

Day 0–2: 48-Hour DFM pack (flow/cool/warp, risk log, preliminary cycle model) → alignment call

-

Day 3–10: Tool build (Al/MUD or pre-hard steel) + texture/polish; EOAT and fixtures designed

-

Day 11–13: T0 in production resin; weight ladder, gate-freeze, cavity balance; preliminary metrology

-

Day 14–18: T1 + FAIR + CMM/scan; DOE window; cosmetic sign-off

-

Day 19–30: PPAP (auto) or IQ/OQ (med); lock golden recipe and alarms

-

Day 31+: PQ / ramp; ship production with PM plan active

Steel-first or complex multi-cavity tools run ~20–28 days to T0 depending on geometry and finish.

RFQ checklist (copy/paste to prevent slippage)

-

Target T1 / SOP dates and milestone gates (DFM, T0, T1, PPAP/IQ-OQ-PQ).

-

CAD (STEP/IGES) + 2D with CTQs/GD&T; cosmetic map; gate/parting preferences.

-

Resin & alternates (UL/FR/UV/food/medical); colour standard and ΔE target.

-

Cavitation plan (pilot → family/multi); slides vs hand-loads; overmold/two-shot/IMD if any.

-

Quality package (FAIR, CMM/scan, CpK targets); data access (MES/OEE/CpK/scrap/kWh/kg).

-

Maintenance & spares expectations; tool storage location; insurance and shipping terms (Incoterms).

-

Support SLAs (response windows, escalation path, on-site support options).

Send your package here → Contact

Why choose the TaiwanMoldMaker.com network

-

Proven programs in consumer, industrial, medical, and labware with references on request.

-

Dedicated technical support—a single accountable owner plus process/tooling specialists.

-

Standardized, robot-ready cells with vision SPC and audit-ready MES data for remote approvals.

-

Bridge-to-scale playbook—start in aluminium/MUD, copy-cavity to steel when demand lands.

Start here:

Custom Mold & Design Maker → Mold Service → Injection Mold → Molding → Customer Examples → Contact