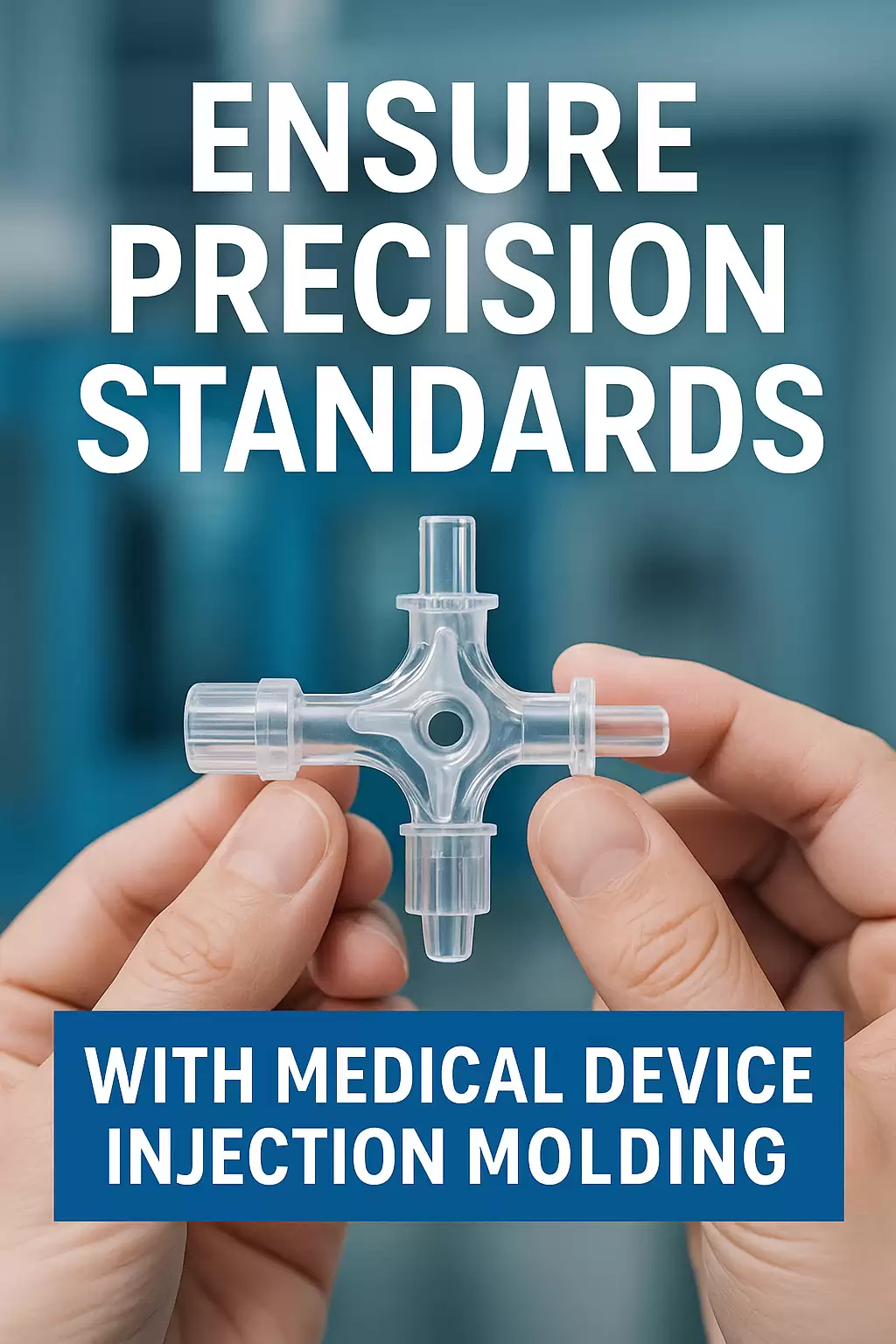

Ensure Precision Standards With Medical-Device Injection Molding for Critical Healthcare Parts

Ensure Precision Standards With Medical-Device Injection Molding for Critical Healthcare Parts

When a plastic component becomes part of an infusion pump, an implantable port, or a point-of-care diagnostic, the cost of dimensional drift or material contamination is measured in patient safety—not scrap bins. Medical-device injection molding therefore operates to a level of rigor far beyond ordinary consumer production. It joins Class 7–8 cleanroom controls, biocompatible polymers, and statistically locked process windows to deliver parts that pass the scrutiny of FDA auditors and surgeons alike. Below is a practical roadmap for design engineers, quality managers, and sourcing teams who need to turn critical healthcare concepts into compliant, reproducible reality.

1 What “Medical-Grade” Really Means in Injection Molding

| Dimension | Requirements | Practical Impact |

|---|---|---|

| Regulatory Framework | ISO 13485-certified QMS, 21 CFR 820 (FDA) compliance, MDR (EU) alignment | Traceable lot genealogy, CAPA, and device-history records (DHRs) |

| Cleanroom Environment | ISO 14644-1 Class 7–8 for molding & assembly | Controls airborne particulates, microbial load, and outgassing |

| Material Control | USP Class VI / ISO 10993 biocompatibility, documented CoA, gamma or EtO compatibility | Prevents cytotoxicity, supports sterilization validation |

| Process Capability | Cavity-pressure sensors; CpK ≥ 1.67 on CTQs | Maintains sub-100 µm tolerances across millions of cycles |

| Lot Traceability | Serialized molds, resin lots, machine parameters, operator ID | Enables rapid recall containment and root-cause analysis |

2 Selecting the Right Medical-Grade Polymer

| Resin | Key Properties | Typical Critical Parts |

|---|---|---|

| Polycarbonate (PC) | High clarity, impact strength, gamma & EtO stable | IV drip chambers, oxygen masks |

| Polyetherimide (PEI / Ultem) | 170 °C continuous use, autoclave stable | Surgical instrument housings, sterilization trays |

| Polypropylene (PP) | Chemical resistance, hinge fatigue, low cost | Luer connectors, syringe barrels |

| Thermoplastic Elastomer (TPE) | Soft-touch, over-mold adhesion, ISO 10993 compliant | Catheter tips, mask seals |

| POM (Acetal) | Low friction, low moisture uptake | Insulin-pump gears, inhaler valves |

Tip Obtain a full ISO 10993 test suite or USP Class VI certificate directly from the resin supplier—don’t rely on distributor literature alone.

3 Design & DFM Rules for Critical Healthcare Parts

-

Draft & Radii ≥ 1° draft; fillets ≥ 0.3 mm to prevent stress risers and ease cleanroom de-molding.

-

Wall Uniformity Keep within ± 15 % to avoid voids that compromise sterilization.

-

Flow Leaders & Tabs Guide the melt to minimize knit lines in functional zones (e.g., lenses, valves).

-

Vent Depth 0.010–0.015 mm for PC/PEI to stop burn-marks without trapping bacteria.

-

Laser Engravable Zones Plan flat lands free of texture for UDI (Unique Device Identification) marking.

4 Process Validation: IQ → OQ → PQ (Example Timeline)

| Week | Phase | Deliverables |

|---|---|---|

| 1 | IQ (Installation Qualification) | Machine calibration, mold inspection, sensor verification |

| 2–3 | OQ (Operational Qualification) | DOE runs bracketing melt temp, hold pressure, cooling time; establish alarm limits |

| 4–6 | PQ (Performance Qualification) | Three consecutive lots at nominal settings; full dimensional CpK study, functional & bioburden tests |

Only after passing PQ is the mold released to commercial production and device-history records initiated.

5 Risk-Mitigation Tactics Only Expert Medical Molders Use

| Risk | Mitigation |

|---|---|

| Resin Moisture | Inline desiccant drying + Karl Fischer verification before each lot |

| Particulate Contamination | HEPA-filtered laminar flow boxes over press clamp and conveyor |

| Tool Wear | Scheduled PM every 50 k cycles; micro-polish inserts; verify cavity dimensions by CMM |

| Parameter Drift | Real-time cavity-pressure feedback; machine shuts if ΔP > 5 % |

| Human Error | Gowning training, barcode operator log-ins, electronic batch records |

6 Case Snapshot – Disposable Dialysis Clamp

| Metric | Commodity Shop | ISO 13485 Medical Molder |

|---|---|---|

| Short Shots (PPM) | 1 800 | 120 |

| Bioburden (cfu/device) | 55 | < 2 |

| PP Resin Lot Traceability | Bag-label only | Full CoA + on-file FTIR scan |

| Device Recall Notices | 1 in 24 months | 0 |

Result: OEM shifted entire clamp family, achieving a 38 % reduction in field complaints and unlocking new EU tenders due to lower bioburden specs.

7 Why Source Through TaiwanMoldMaker.com?

-

Cleanroom Network Multiple ISO Class 7/8 molding halls with automated take-out and enclosed conveyors.

-

Regulatory Documentation Ready ISO 13485 certificates, FDA master files, and full validation templates.

-

Scientific-Molding Centers RJG-trained technicians, cavity-pressure sensors, and eDART data for each run.

-

Rapid Material Access Biocompatible PC, PP, PEI, POM, and TPE grades stocked locally—samples in < 5 days.

-

End-to-End Integration Pad-printing, laser UDI, ultrasonic welding, and cleanroom assembly under one roof—fewer handling risks.

8 Action Plan—Launch Your Critical Part With Confidence

-

Define CTQs & Regulatory Class (include sterilization method).

-

Submit CAD & Material Preference to TaiwanMoldMaker.com for 48-h DFM + validation timeline.

-

Approve Tool-Steel & Cleanroom Level aligned with ISO 13485.

-

Execute IQ/OQ/PQ with real-time data sharing.

-

Release to Production and receive serialized lots with full electronic DHRs ready for FDA audits.

Ready to Build Precision Into Every Shot?

Upload your files and spec sheet to TaiwanMoldMaker.com. We’ll connect you to medical-grade injection-molding partners who fuse scientific molding, cleanroom discipline, and global regulatory expertise—guaranteeing your critical healthcare parts meet precision standards every time.