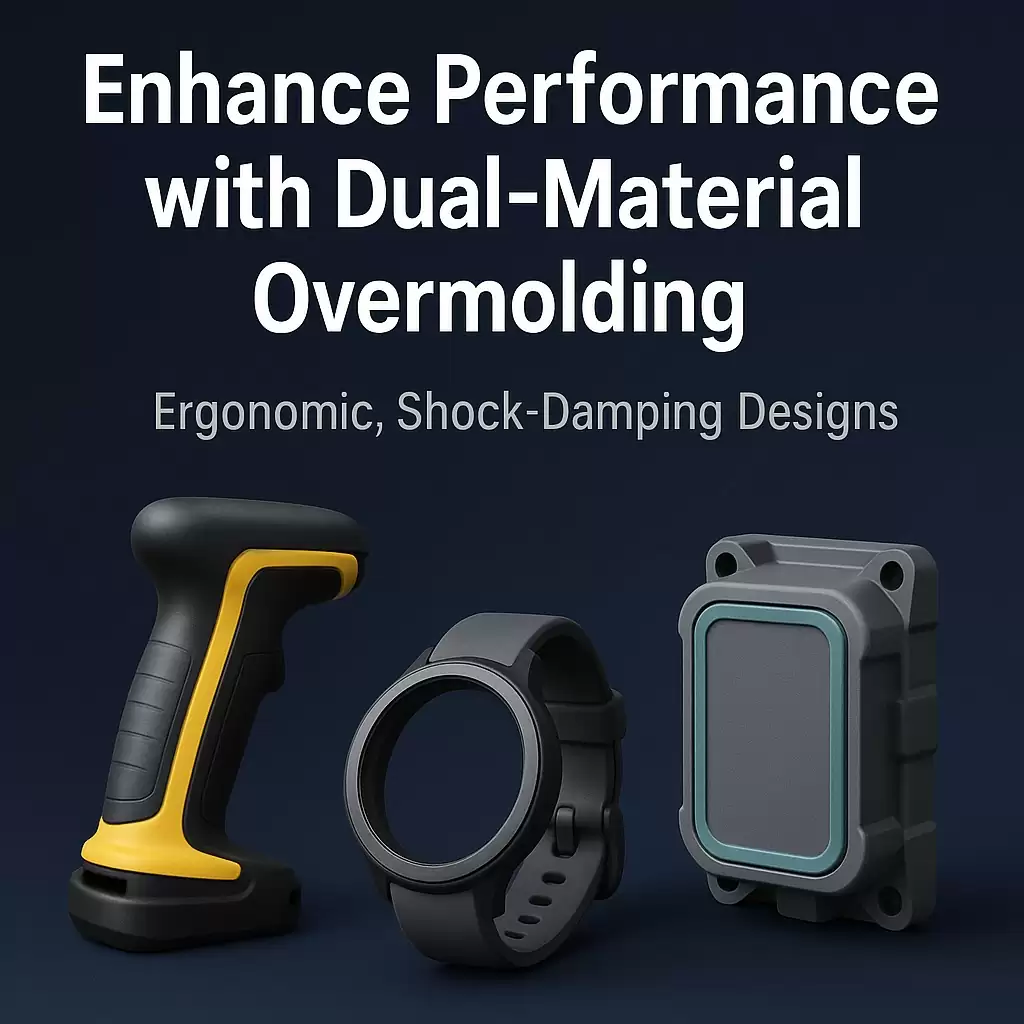

Enhance Performance with Injection Overmolding for Dual-Material, Ergonomic Designs

Enhance Performance with Injection Overmolding for Dual-Material, Ergonomic Designs

1 Why Overmolding Matters in 2025

Today’s users expect products that feel as good as they function. Whether it’s a power-tool handle that reduces fatigue or a wearable sensor that blends seamlessly against the skin, dual-material overmolding is the proven route to deliver rugged performance and premium ergonomics—all in a single, repeatable molding cycle.

2 What Exactly Is Injection Overmolding?

Definition – Injection overmolding is a two-step molding process in which a pre-molded substrate (rigid plastic, metal, PCB, or even fabric) is re-inserted into a second mold and encapsulated with a second resin—often a soft thermoplastic elastomer (TPE/TPU) or contrasting-color rigid polymer.

Unlike traditional two-shot (2K) molding that happens inside one rotating tool, overmolding allows separate tools or presses, making it ideal for mid-volume programs or complex inserts.

3 Five Ways Overmolding Boosts Product Performance

| Benefit | Real-World Impact |

|---|---|

| Enhanced Grip & Comfort | Soft-touch surfaces lower hand-arm vibration and improve user safety in power tools, sports equipment, and medical devices. |

| Shock & Vibration Damping | Elastomeric overmolds act as energy absorbers—essential for ruggedized electronics and IoT sensors. |

| Integrated Sealing (IP-Rated) | In-mold TPE gaskets eliminate O-rings and secondary assembly, achieving IP67-IP68 water resistance. |

| Aesthetic Differentiation | Two-tone color breaks, logos, or metallic accents land straight out of the press—no paint, no decals. |

| Part & Assembly Reduction | Consolidate screws, adhesives, and sub-components into one molded piece, cutting assembly time 20–40 %. |

4 Material Pairing & Design Best Practices

-

Check Adhesion Compatibility

Reference resin suppliers’ overmold charts (e.g., PC + TPU, ABS + SEBS, GF-PA + TPV). Always validate with 180° peel-test coupons. -

Optimize Wall Thickness

Second-shot thickness ≈ 60–100 % of the substrate wall to avoid sink and cooling stress. -

Use Positive Mechanical Locks

Built-in undercuts, through-holes, or dovetails guarantee bond strength even under thermal cycling. -

Gate on the Thickest Section

Ensures uniform flow and minimizes knit lines on Class-A surfaces. -

Simulate & Pilot

Run Moldflow for dual-material flow fronts; follow with a short DOE at T-0 to lock CpK ≥ 1.67.

5 Ideal Applications & Industries

| Sector | Typical Overmolded Parts |

|---|---|

| Power Tools | Anti-slip handles, trigger boots, battery housings |

| Medical Devices | Catheter hubs, insulin pens, biocompatible seals |

| Consumer Electronics | Earbuds, smartwatch bezels, phone bumpers |

| Automotive Interiors | Soft-feel knobs, HVAC wheels, illuminated bezels |

| Industrial IoT | IP67 sensor enclosures, vibration-isolating brackets |

6 Case Snapshot – Redesigning a Power-Tool Handle

| Metric | Conventional Rigid Handle | Overmolded Dual-Material Handle |

|---|---|---|

| Assembly Parts | 5 (handle, grip sleeve, screws) | 1 |

| Cycle Time | N/A (manual assembly) | 38 s in-mold |

| User Grip Force | 37 N | 24 N (35 % less) |

| Warranty Claims (12 mo) | 1 200 ppm | 230 ppm |

Result: A global OEM shaved US $1.10 per unit in labor and scrap while boosting customer satisfaction scores by 22 %.

7 Bring Your Dual-Material Concept to Life—Fast

TaiwanMoldMaker.com unites ISO-certified partners equipped with dedicated overmolding presses from 60 t micro cells to 450 t rotary systems.

-

48-Hour DFM Pack – gating, shut-off, adhesion lab schedule, cost model

-

Prototype-to-Production Credits – roll Al bridge-tool fees into H13 steel cavities

-

Live MES Dashboards – watch CpK, OEE, and scrap trends in real time via API

Quick Links:

✔️ Customer Examples

8 Next Steps

-

Upload Your CAD & Resin Targets—STEP, IGES, or native files.

-

Schedule a 30-Min Virtual DFM Review—align on shut-offs, gates, cosmetic zones.

-

Approve Dual-Path Quote—Al bridge tool + steel production tool.

-

Receive T-0 Parts in as Little as 3 Weeks—ready for lab, field, or PPAP testing.

Final Takeaway

Injection overmolding turns ordinary parts into high-performance, ergonomic products that delight users and streamline production. Partner with TaiwanMoldMaker.com to hit aggressive launch dates, shrink assembly costs, and achieve unbeatable part quality—all with one PO. Upload your files today and receive a no-obligation feasibility study within 48 hours.