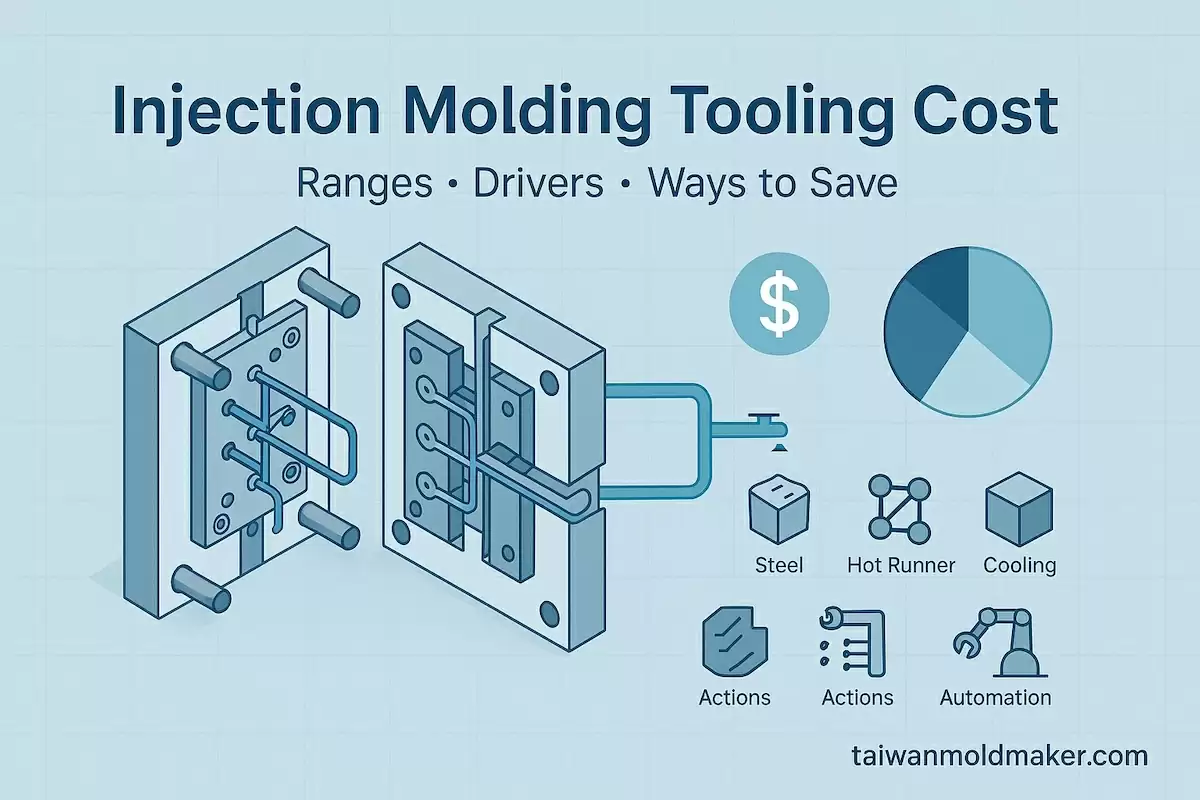

Injection Molding Tooling Cost: Ranges, Drivers & Proven Ways to Save

Injection Molding Tooling Cost: Ranges, Drivers & Proven Ways to Save

Injection Molding Tooling Cost: What Drives It (and How to Control It)

Tooling (the mold) is the largest up-front cost in injection molding. Your final part price depends heavily on how the tool is designed—steel choice, cavity count, hot runner strategy, cooling design, and any actions (slides/lifters). This guide explains cost drivers, realistic ranges, and proven tactics to hit budget without sacrificing quality or time-to-market.

What Makes Up “Tooling Cost”?

-

Mold Base & Steel

-

Aluminum → fastest/lowest for prototypes and short runs

-

Pre-hard/H13/S136 → durable for production; corrosion-resistant for clear/medical parts

-

-

Cavities & Layout

-

More cavities = lower piece price but higher tool cost, larger press, longer DFM/validation

-

-

Runner & Gating

-

Cold runner (lowest capex, higher resin waste)

-

Hot runner / valve gate (higher capex, faster cycles, best cosmetics, no cold sprues)

-

-

Cooling Architecture

-

Drilled lines (standard) vs conformal cooling (AM inserts) and high-κ copper cores

-

-

Actions & Complexity

-

Slides, lifters, unscrewing, collapsible cores, 2K/overmold, insert molding

-

-

Finish & Metrology

-

SPI textures/polish, optical zones, checking fixtures, FAIR/CMM/GR&R pack

-

-

Automation Readiness

-

EOAT interfaces, robot clearance, in-cell mark/weld/leak-test nests

-

Typical Cost Ranges (Reference Only)

| Tool Type | Typical Use | Ballpark Tooling Cost* | Notes |

|---|---|---|---|

| Aluminum single-cavity | EVT/DVT, 1–3k shots | US$4k–15k | Fastest lead time |

| Hybrid (Al + steel inserts) | Abrasive resins, local wear | US$8k–25k | Extends shot life |

| Steel single-cavity (H13/S136) | Production pilot | US$15k–40k | Cosmetic/optical options |

| Multi-cavity 2–4x (cold runner) | Low/med volume | US$20k–60k | Higher resin usage |

| Multi-cavity 4–16x (hot/valve) | High volume | US$40k–180k+ | Balance & manifolds drive cost |

| 2K / overmold | Dual materials | US$60k–250k+ | Rotary/indexing hardware |

| Unscrewing / collapsible core | Threads/undercuts | US$40k–150k+ | Mechanisms & controls |

| Conformal-cooled insert set | Cycle/warp control | +US$2k–15k | ROI via cycle reduction |

*Actuals vary by part size, surface class, resin, metrology/qualification scope, country of build, and exchange rates.

Lead Time Benchmarks

-

Aluminum single-cavity: 7–15 days

-

Steel single-cavity: 3–5 weeks

-

Multi-cavity hot runner: 5–10 weeks

-

Complex (2K/unscrew/conformal): 8–14+ weeks

(Lead times include DFM → machining → assembly → T0/T1, excluding major design changes.)

Cost vs Piece Price: Finding the Break-Even

A higher-cavity hot-runner tool costs more up front but reduces cycle time, scrap, and resin waste, dropping the per-part cost.

Simple amortization check (rule-of-thumb):

Break-even qty ≈

Example: Upgrading from 1-cavity cold to 4-cavity valve gate adds US$50k but saves US$0.08/part → break-even ≈ 625k parts.

Hidden Costs (Often Missed)

-

Cooling imbalance → longer cycles/warp → recurring scrap costs

-

Under-sized gates → pack starvation → sink & rework

-

Maintenance access → poor SMED design raises downtime cost

-

Metrology gaps → delays at PPAP/IQ-OQ-PQ

-

Dutiable value → some regions let you service-weight billing (engineering services separated from tool hardware). Confirm with your broker.

How to Lower Tooling Cost Without Hurting Quality

-

Design for Manufacturability (DFM) early

-

Uniform walls; ribs 40–60% of wall; generous draft (≥0.5° polished / ≥1.0–1.5° textured)

-

-

Right-size cavity count

-

Model demand & break-even; consider family tools or modular inserts for variants

-

-

Bridge → Steel strategy

-

Start with aluminum/hybrid; credit a portion toward the steel copy once demand confirms

-

-

Choose runner strategy by SKU math

-

Cold runner for tiny volumes; valve gate for cosmetic/high-volume parts

-

-

Cycle time pays for itself

-

Add conformal cooling or high-κ inserts where ROI < 12–18 months

-

-

Standardize components

-

Ejectors, date wheels, manifolds, heaters/TCs; easier spares & lower downtime

-

-

Instrument at least one cavity

-

Cavity pressure + thermocouples → locks a wider process window (lower scrap)

-

Example Cost Model (Consumer Housing, PC/ABS)

| Scenario | Tool | Est. Tooling | Cycle | Est. Unit Cost (100k/yr)* | Notes |

|---|---|---|---|---|---|

| A | 1-cavity, cold | US$28k | 28.5 s | US$1.18 | Highest piece price |

| B | 2-cav, hot tip | US$55k | 22.5 s | US$0.84 | Better balance/cosmetics |

| C | 4-cav, valve gate + conformal | US$105k | 18.9 s | US$0.63 | Best TCO; fastest payback |

*Unit cost includes press time, labor, energy, amortized tool, resin (no packaging/logistics). Numbers are illustrative.

RFQ Template (Copy/Paste)

Subject: RFQ – Injection Molding Tooling Cost & Options

Attachments: STEP/IGES + 2D with CTQs & cosmetic map

-

Annual volume & ramp plan:

-

First PO quantity & target ship date:

-

Resin & color (grade/MFR; GF/FR/UV):

-

Surface class & texture (SPI code; ΔE tolerance):

-

Tooling preference: (aluminum / hybrid / steel; cavity count; hot vs cold runner; valve gate?)

-

Actions/features: (slides, lifters, unscrewing, collapsible cores, 2K/overmold, inserts)

-

Cooling goal: (cycle target; conformal cooling ROI check)

-

Inspection pack: (FAIR, CMM/scan, GR&R; PPAP/IQ-OQ-PQ if needed)

-

Automation/readiness: (EOAT, in-cell mark/weld/leak, vision SPC)

-

Commercial: (bridge-to-steel credits; service-weighted billing feasibility; Incoterms)

What You Get with TaiwanMoldMaker.com

-

48-Hour DFM & Cost Pack → gating/cooling map, cycle model, multi-scenario tool quotes

-

Bridge-to-Steel options + copy-cavity path when demand confirms

-

Hot runner selection (valve/sequential) & conformal cooling ROI estimates

-

Scientific molding DOE; cavity-pressure window and golden recipe on Day 1

-

Metrology first: FAIR, CMM/blue-light, GR&R; ΔE/gloss for A-class surfaces

-

Dual-plant capacity (Taiwan + SE Asia) and MES dashboards (OEE, CpK, scrap, energy)

Quick Links

-

Custom Mold & Design Maker

https://www.taiwanmoldmaker.com/product/custom-mold -

Mold Service

https://www.taiwanmoldmaker.com/product/mold-service -

Injection Mold

https://www.taiwanmoldmaker.com/product/injection-mold -

Customer Examples

https://www.taiwanmoldmaker.com/product/customer-examples

Call to Action

Need a side-by-side tooling cost plan (cold vs hot, 1× vs 4×, with/without conformal cooling)?

Send CAD and volumes to receive a 48-Hour DFM & Cost Pack with break-even analysis and a realistic launch schedule.

Request an Instant Quote → https://www.taiwanmoldmaker.com/contact