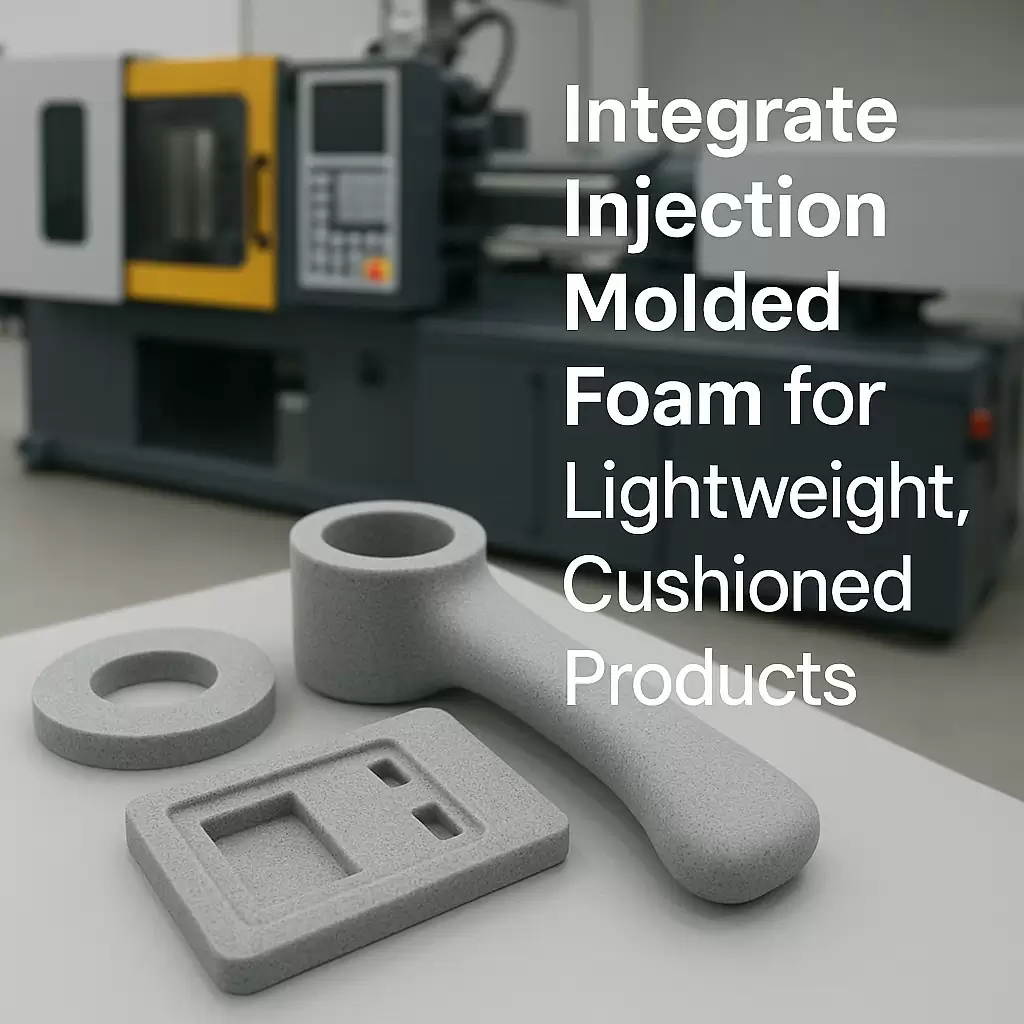

Integrate Injection-Molded Foam for Lightweight, Cushioned Products

Integrate Injection-Molded Foam for Lightweight, Cushioned Products

Foam injection molding—sometimes called structural-foam molding or micro-cellular (MuCell®) molding—combines a gas-charged polymer melt with conventional injection molding to create a self-skinned, foamed core. The result is a part that weighs 10–35 % less than a solid counterpart while adding built-in cushioning, vibration damping, and excellent stiffness-to-weight ratios. Below is a practical guide to designing, tooling, and scaling foam-molded parts with help from TaiwanMoldMaker.com.

1 Why Choose Injection-Molded Foam?

| Advantage | Design Payoff |

|---|---|

| Weight Reduction (10–35 %) | Lower shipping cost, easier handheld use, energy savings in vehicles |

| Integral Skin | Hard, cosmetic exterior surface with a cellular core—no secondary over-mold needed |

| Warpage Resistance | Internal gas pressure balances shrink, holding tight flatness on large panels |

| Thick-Wall Freedom | Walls up to 15 mm without sink marks—perfect for handles and grab rails |

| Vibration & Impact Damping | Microscopic cells absorb energy, protecting electronics and users |

| Shorter Cycle Times | Lower melt density fills faster; controlled pressure reduces clamp tonnage |

2 Process Basics

-

Polymer/Gas Blending

– Either physical foaming (SCF CO₂ / N₂) or chemical blowing agents mix with molten resin. -

Low-Pressure Filling

– The shot enters the cavity 35–70 % under normal injection pressure, allowing gas to expand. -

Self-Skin Formation

– Outer layers freeze against the mold wall, forming a solid skin; the core continues to foam. -

Packing & Cooling

– Internal cell pressure replaces conventional pack/hold, cutting clamp tonnage by up to 50 %.

3 Material & Additive Options

| Resin Family | Typical Density Drop | Best-Fit Applications |

|---|---|---|

| PP / High-Impact PP | 10–15 % | Appliance housings, auto trim |

| PC / PC-ABS | 15–20 % | Helmet shells, rugged electronics |

| PA 6/66 + GF | 20–25 % | Power-tool frames, drone airframes |

| HIPS / ABS | 15–25 % | Furniture components, luggage shells |

| TPU / TPE | 30 %+ | Soft grips, medical cushioning pads |

Tip: Add talc or glass fibers when stiffness must rise faster than weight falls.

4 Design Guidelines

-

Wall Thickness 2–15 mm — thicker walls yield more weight savings with no sink.

-

Draft Angle ≥ 1.5° — foam parts shrink less but still need smooth ejection.

-

Ribs & Bosses 0.7–0.9 × wall — foamed core reduces sink, allowing generous features.

-

Flow Leaders Add flow channels on large panels to guide uniform cell growth.

-

Texturing Medium VDI textures mask swirl and “tiger stripes” common to foam surfaces.

5 Typical Part Families

| Sector | Injection-Foam Parts |

|---|---|

| Automotive | EV battery covers, seat backs, spoiler cores |

| Medical & Life-Science | Lightweight walker frames, diagnostic equipment shells |

| Consumer Products | Bicycle helmets, protective phone cases, stroller components |

| Industrial & IoT | Vibration-damped sensor mounts, drone fuselages |

| Furniture & Appliances | Chair shells, refrigerator door liners |

6 Validation Checklist

-

Cell-Structure SEM Analysis — confirms uniform density drop.

-

Impact / Drop Testing — proves energy absorption vs. solid equivalents.

-

UL 94 / FMVSS Flame Tests — critical for transport and appliance parts.

-

ISO 179 Charpy — documents toughness improvement over talc-filled solids.

7 How TaiwanMoldMaker.com Makes Foam Molding Simple

| Challenge | Our Built-In Solution |

|---|---|

| SCF dosing accuracy | MuCell®-licensed screws & shut-off nozzles on 60–850 t presses |

| Cosmetic “swirl” | Moldflow® gas-front simulations + balanced runner layouts |

| Clamp-force oversizing | Low-pressure fill reduces tonnage; smaller presses lower part cost |

| Multi-Material shells | Two-shot tooling merges solid aesthetic faces with foamed structural backs |

| ESG targets | Density reduction = ≤ 0.45 kg CO₂ saved per kg of resin vs. solid parts |

One-Click Service Links

8 Next Steps—Lighten the Load

-

Upload your CAD & target weight-reduction goal.

-

Receive a 48-Hour Foam DFM Pack—gas dosage, gate plan, and cost model.

-

Approve the bridge-tool quote (Al 7075 or P20).

-

See foam first articles in as little as three weeks with density and impact-test data attached.

Lighter, tougher, quieter—foamed parts check all three boxes. Partner with TaiwanMoldMaker.com to integrate injection-molded foam into your next product and outpace the competition on weight, performance, and cost.