Evaluate Structural Foam Molding Companies for Large, Lightweight Designs

Evaluate Structural Foam Molding Companies for Large, Lightweight Designs

Evaluate Structural Foam Molding Companies for Large, Lightweight Product Designs

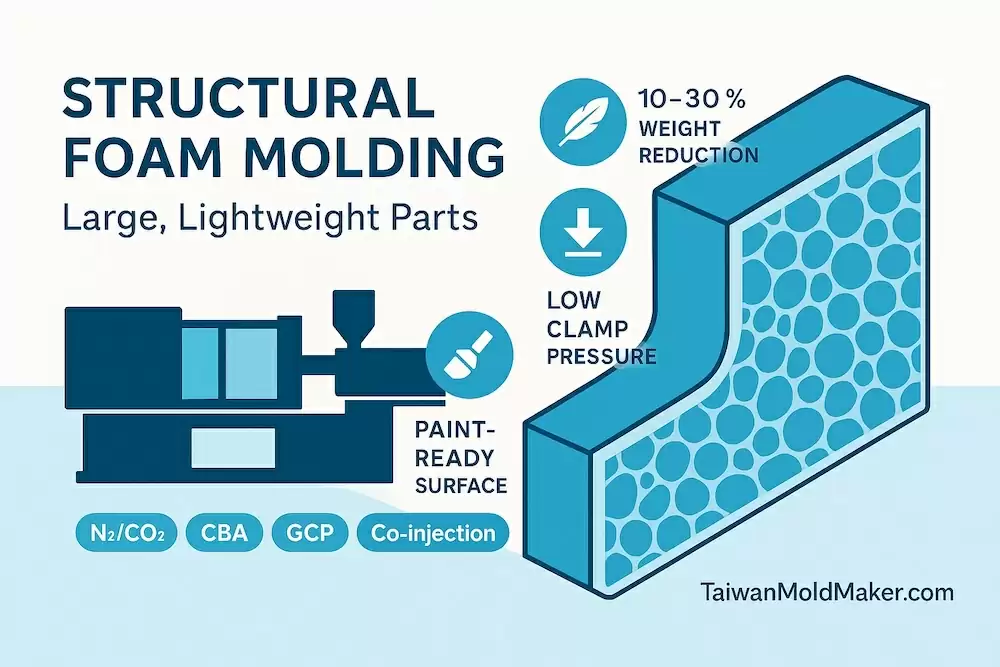

When parts get big and thick—but still need stiffness, low warp, and attractive cost—structural foam molding shines. Low-pressure foaming creates a cellular core with solid skins, delivering high stiffness-to-weight, reduced sink, and relaxed clamp tonnage. The key is picking a supplier with the right presses, foaming tech, tooling know-how, and finishing.

What Is Structural Foam Molding?

SFM injects a melt charged with a blowing agent (physical N₂/CO₂ or chemical) into a heated mold. As pressure drops, cells nucleate and expand, forming a sandwich structure (solid skins + foamed core). Variants include:

-

Physical foaming (e.g., MuCell®): precise gas dosing → fine, uniform cells

-

Chemical blowing agents (CBA): pellet-based; economical for large parts

-

Gas counterpressure (GCP): suppresses swirl/knit marks for better surfaces

-

Co-injection “skin-core”: virgin solid skin, foamed core (often regrind/filler)

Best fit: panels, machine bases, appliance/kiosk housings, carts, pallets/totes, furniture components, medical/equipment shrouds.

When to Choose SFM (vs. Conventional Injection/SMC/Thermoform)

-

Large envelopes & thick sections: ~4–25+ mm without sink/read-through

-

Weight reduction: typical density cut 10–30% with stiffness maintained

-

Lower clamp/press stress: great for very large molds and long flow paths

-

Cost: lower tooling vs. SMC or high-tonnage multi-rib thermoplastic designs

-

Surface: paintable; GCP/IMC or texture can mask swirl

What to Look For in a Structural Foam Molder (Scorecard)

| Category | What “Good” Looks Like | Why It Matters |

|---|---|---|

| Press & Platen Size | Large-platen, low-pressure machines; multi-kg shots | Fits big tools, reduces clamp risk |

| Foaming Tech | Physical foaming (N₂/CO₂), CBA, GCP, co-injection | Surface quality + weight targets |

| Tooling Know-How | Low-pressure venting, heated molds, balanced gating; thick-section DFM | Controls swirl, warp, knit lines |

| Materials Depth | PP/HDPE/HIPS, PC/ABS, talc/mineral-fill, UV/FR grades | Mechanical/UV compliance |

| Metrology for Big Parts | Blue-light/laser scan, large CMM, custom fixtures | Flatness & datum control |

| Finishing & Assembly | In-cell trim/routing, primer/paint, graphic/IMD, hardware install | Paint-ready, fewer moves |

| Automation & QC | EOAT demold, vision cosmetics, SPC; MES with genealogy | Stable cosmetics and traceability |

| NPI Speed | 48-hour DFM pack; pilot tools; skin-core trials | Faster risk burn-down |

| Logistics | Returnable racks, pallet maps, protective films | Lower freight damage |

| Sustainability | Regrind rules, density reduction reporting (kWh/kg) | Lower TCO and ESG wins |

Grading tip: A-tier ≥ 85/100 using the table above; require evidence (photos, DOE, surface maps).

Design Rules for Structural Foam Parts (Quick Wins)

-

Walls: 4–12 mm typical (thicker OK); add generous radii (≥ 3 mm)

-

Ribs: fewer than solid molding; when used, height modest; target 50–70% of wall for base thickness pads

-

Bosses/Fasteners: use landing pads instead of tall bosses; spread loads through the skin

-

Draft: 1–2° (more for deep textures)

-

Gates: fan/edge gates and multiple feeds minimize swirl; GCP improves A-surfaces

-

Tolerances: set datum-based specs; large parts often ±0.5–1.0 mm per 300 mm (confirm per geometry)

-

Cosmetics: plan texture or paint; specify ΔE/gloss and visible knit criteria

Process Window (Starting Points—tuned via DOE)

-

Density reduction: 10–30% vs. solid

-

Mold temp: typically higher than solid injection to improve skin & adhesion

-

Fill/pack: low pressure; GCP to delay cell growth → better surface

-

Demold: governed by section thickness and paint plan; allow cure/anneal as needed

Typical Outcomes with Optimized SFM Cells

| KPI | Conventional Thick-Wall | Structural Foam |

|---|---|---|

| Part mass (1 m² panel) | 100% | 70–85% |

| Visible sink/read-through | Present | Minimal |

| Clamp tonnage required | High | Lower |

| Warp @ datum | Higher | Lower (balanced gating + GCP) |

| Paint rework | 5–8% | ≤2–3% (with GCP/IMC & temp control) |

Representative; actuals depend on geometry, resin, and tool design.

SFM vs. Alternatives (Buyer’s Snapshot)

| Attribute | SFM (Foamed Thermoplastic) | Solid Injection | SMC/Compression | Thermoforming |

|---|---|---|---|---|

| Tooling cost | Low–Medium | Medium–High | Medium | Low |

| Weight/stiffness | High stiffness-to-weight | High weight for stiffness | Very stiff, heavier | Light, needs ribs/backers |

| Surface | Paintable; texture | Best raw surface | Paint required | Paint/film common |

| Tolerance | Medium | Best | Medium | Looser |

| Cycle | Medium | Fastest | Slow–Medium | Fast |

| Part size | Excellent | Good | Excellent | Excellent |

RFQ Template (Copy/Paste)

Subject: RFQ – Structural Foam Molding (Large, Lightweight Part)

Attachments: STEP/IGES + 2D with CTQs & cosmetic map

-

Part envelope (L×W×H) & target mass:

-

Resin & additives: (PP/HDPE/PC-ABS; talc/mineral; FR/UV)

-

Density reduction target: (10–30%) and stiffness goals

-

Surface plan: (texture vs. paint vs. IMC); ΔE/gloss targets

-

Tolerance/flatness hotspots & fixtures required:

-

Preferred process: (physical foaming / CBA / GCP / co-injection skin-core)

-

Volumes: pilot + annual; reorder cadence

-

Inspection pack: (FAIR, blue-light, GR&R, paint adhesion, CpK at CTQs)

-

Packaging/logistics: (racks, films, labels, pallet map)

-

Target dates (T0/T1/buy-off/SOP) & Incoterms:

How We Help (TaiwanMoldMaker.com Network)

-

48-Hour DFM Pack: gating/venting/GCP plan, density & stiffness model, cosmetic risk map

-

Tooling: aluminum/steel low-pressure molds; co-injection “skin-core” where needed

-

Process: physical/CBA foaming, GCP, DOE to tune cell size and surface quality

-

Finishing: in-cell trim/routing, primer/paint/IMC, graphics; vision cosmetics

-

Quality: FAIR, blue-light scan, custom fixtures, ΔE/gloss, adhesion tests; MES with genealogy

-

Logistics: returnable racks, protective film, pallet maps; Taiwan + SE Asia dual-plant coverage

Quick Links

-

Custom Mold & Design Maker

https://www.taiwanmoldmaker.com/product/custom-mold -

Mold Service

https://www.taiwanmoldmaker.com/product/mold-service -

Injection Mold

https://www.taiwanmoldmaker.com/product/injection-mold -

Customer Examples

https://www.taiwanmoldmaker.com/product/customer-examples

Call to Action

Evaluating structural foam for a large, lightweight design? Send CAD and targets to get a 48-Hour SFM DFM & Cost Pack—including density options, cosmetic plan (GCP/paint/IMC), cycle model, and launch schedule.

Request an Instant Quote → https://www.taiwanmoldmaker.com/contact