How Does Injection Molding Work? Process, Design Rules & Cost Drivers

How Does Injection Molding Work? Process, Design Rules & Cost Drivers

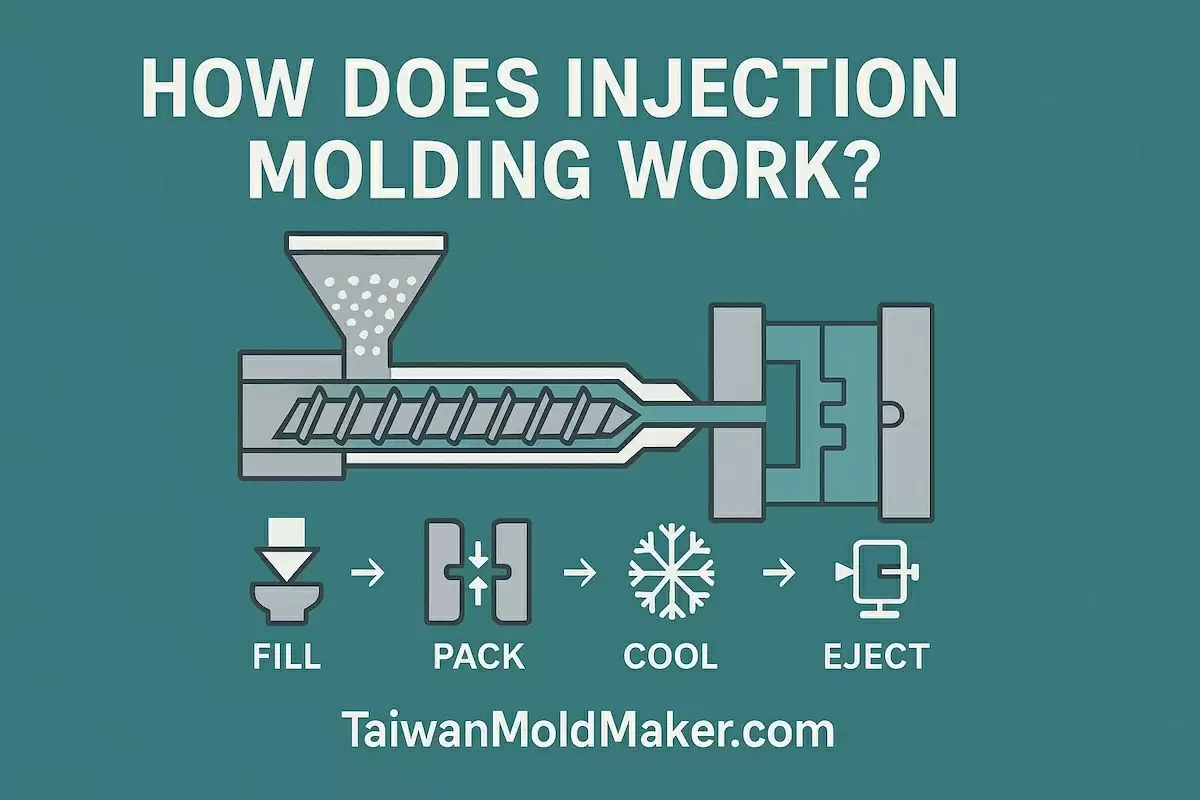

How Does Injection Molding Work?

A Practical Guide from CAD to Packed Parts

Injection molding makes high-repeatability plastic parts by melting pellets, forcing the melt into a precision mold, cooling it into shape, and repeating the cycle—often millions of times—with stable quality and cost.

Core Idea (30 seconds)

-

Pellets in → melt made (plasticized by a screw/barrel).

-

Melt in → cavity filled (injection + packing through a gate/runner).

-

Heat out → part solid (cooling circuits remove heat).

-

Part out → next shot (open mold, eject, close, repeat).

Every improvement you make in mold design, gating, cooling, and process control shrinks cycle time and raises CpK.

The Equipment at a Glance

-

Hopper + Dryer – conditions hygroscopic resins (e.g., PA, PETG, PBT).

-

Screw/Barrel – melts and meters resin; back pressure and screw speed set homogeneity.

-

Nozzle – couples melt to the mold’s sprue or hot runner.

-

Mold (Tool) – steel/aluminum plates with cavity and core; includes gates, runners, cooling channels, vents, and an ejection system.

-

Clamping Unit – opens/closes the mold and holds it shut during injection.

-

Controls & Sensors – machine I/O plus cavity pressure and thermocouples for scientific molding.

-

Automation (optional) – robot demold, insert loading, inline mark/weld, vision SPC.

The Cycle (Step-by-Step)

-

Mold Close & Clamp

-

Machine builds clamp force to seal the parting line.

-

-

Injection (Fill)

-

Screw drives forward, pushing melt through runner → gate → cavity.

-

Fill speed/pressure set flow, shear, knit-line positions, and gate blush risk.

-

-

Pack & Hold

-

Extra pressure compensates shrinkage while the gate is still molten.

-

Critical for controlling sink, voids, and dimensions at CTQs.

-

-

Cooling

-

Most of the cycle time. Balanced cooling circuits extract heat until the gate freezes and the part solidifies enough to eject without distortion.

-

-

Mold Open & Eject

-

Ejector pins/strippers/air blasts release the part; robot retrieves; runners are trimmed or auto-degated.

-

-

Plasticizing (Recover)

-

Screw retracts and re-melts pellets for the next shot; dosing sets shot size.

-

Golden rule: set V/P transfer (velocity → pressure) using cavity pressure when possible—not just screw position.

Materials You’ll See Most

-

Commodity: PP, HDPE, HIPS → cost-effective, good flow.

-

Engineering: ABS, PC/ABS, PC, PA6/66 (±GF), POM, PETG → strength, heat, cosmetics.

-

High-Heat: PBT-GF, PEEK, PPS, PEI (ULTEM™) → harsh environments, E/E & auto.

-

Elastomers: TPE/TPV → soft-touch overmold, seals.

-

Additives: glass/mineral fill, FR (UL 94), UV, color MB, lubricants.

Mold Essentials That Make or Break the Part

-

Gates & Runners – size and placement drive shear, weld lines, pack, and vestige.

-

Cooling – channel diameter/depth/pitch and conformal cooling flatten ΔT and reduce warp.

-

Steel & Coatings – H13/S136/M300; TiN/DLC for glass-filled wear zones; SPI polish for A-class or optics.

-

Venting – micro-vents or vacuum help thin walls and prevent burn marks.

-

Ejection – guided ejectors/strippers prevent scuffing and knocks on ribs/bosses.

Design-for-Molding (DFM) Cheatsheet

-

Uniform walls; ribs at 40–60% of wall to avoid sink.

-

Draft: ≥1.0–1.5° textured; ≥0.5° polished faces.

-

Bosses: ID ≈ 60–70% of OD; fillet bases; rib tie-ins.

-

Living hinges (PP): hinge thickness 0.25–0.50 mm, flow across hinge.

-

Gate away from A-class; use fan/film on large skins; sequential valves for long flow paths.

-

GF materials: align gate/flow with load paths to control warp and fiber orientation.

Quality, Data, and “Scientific Molding”

-

Cavity pressure defines V/P transfer, pack time, and window robustness.

-

DOE (fill speed, melt/mold temps, pack profile, cooling) maps the stable process.

-

Metrology first: FAIR + CMM/blue-light scan, GR&R at CTQs; ΔE/gloss for branded surfaces.

-

SPC & MES: live OEE, CpK, scrap, energy (kWh/kg) with genealogy to lot level.

Common Defects → Fast Root Causes

| Symptom | Likely Cause | First Fixes |

|---|---|---|

| Short shots | Low melt temp / small gate / poor vent | Raise melt/mold temp; enlarge gate; add vents |

| Sink at bosses | Starved pack / thick mass | Increase pack; core heavy bosses; ribs 40–60% |

| Warp/flatness | Uneven cooling / fiber bias | Balance cooling; conformal inserts; move/sequence gates |

| Weld line weakness | Cold fronts / high glass | Raise mold temp; fan gate; sequential valves |

| Blush/jetting | High shear at gate | Larger gate; shorter land; hotter mold; slower initial fill |

| Splay/voids | Moisture/air | Dry resin; check check valves and vents |

Cost Drivers (What Buyers Should Watch)

-

Tooling complexity (actions, 2K/overmold, hot runner brand/valves).

-

Cavity count & balance (directly impacts piece price).

-

Cycle time (cooling rules).

-

Resin grade (GF/FR/UV add cost & wear).

-

Scrap & rework (vision SPC helps).

-

Post-ops (paint, laser, weld, assembly).

From Prototype to Production: A Typical Path

-

Upload CAD + targets (tests, resin, volumes).

-

48-Hour DFM Pack – gating/cooling map, risk register, cycle & CPU model.

-

Quick-turn tool (aluminum or hybrid) → T0/T1 DOE, cavity-pressure curves.

-

FAIR + functional/cosmetic checks → refine.

-

Copy-cavity to steel; add automation & vision; qualify (PPAP/IQ-OQ-PQ).

-

SOP with MES guardrails and PM schedule.

FAQs

Is 3D printing enough before tooling?

Great for concept fit, but only molding reveals true resin behavior, weld lines, and gate/cooling effects.

What’s a realistic tolerance?

Many CTQs land in ±0.05–0.10 mm on small/medium parts; micro-features tighter with the right steel and process.

When do I need a hot runner?

Multi-cavity, cosmetic surfaces, or long flow paths—valve gates cut stringing and improve balance.

What We Do (TaiwanMoldMaker.com Network)

-

Design & Tooling: aluminum → hybrid → full steel; valve-gated hot runners, conformal cooling.

-

Processes: 2K/overmold, thin-wall, optics, LSR, gas-assist, RHCM.

-

Quality: ISO 9001 network; IATF 16949 / ISO 13485 available; FAIR/CMM/GR&R/PPAP.

-

Automation & Data: robots, in-cell finishing, vision SPC, MES dashboards for OEE/CpK/scrap/energy.

Quick Links

-

Custom Mold & Design Maker – rapid DFM & tooling strategy

https://www.taiwanmoldmaker.com/product/custom-mold -

Mold Service – aluminum, hybrid, and steel tooling

https://www.taiwanmoldmaker.com/product/mold-service -

Injection Mold – materials & processes overview

https://www.taiwanmoldmaker.com/product/injection-mold -

Molding – automated production with traceability

https://www.taiwanmoldmaker.com/product/molding -

Customer Examples – case snapshots and results

https://www.taiwanmoldmaker.com/product/customer-examples

Call to Action

Ready to turn CAD into repeatable molded parts? Send your files and targets to receive a 48-Hour DFM & Cost Pack with a gating plan, cooling concept, cycle model, and timeline.

Request an Instant Quote → https://www.taiwanmoldmaker.com/contact