Reduce Material Usage With Gas-Assist Injection Molding for Lighter Plastic Parts

Reduce Material Usage With Gas-Assist Injection Molding for Lighter Plastic Parts

Weight reduction is no longer a nice-to-have—it is a mandate for everything from premium furniture and fitness equipment to smart-home devices and commercial appliances. Gas-assist injection molding (GAIM) is a proven method to cut resin consumption by 10-40 %, lower clamp tonnage, and deliver warp-free, high-cosmetic parts. Below is a practical guide to determine if GAIM fits your next project and how partnering with TaiwanMoldMaker.com helps you launch lighter, stronger products—fast.

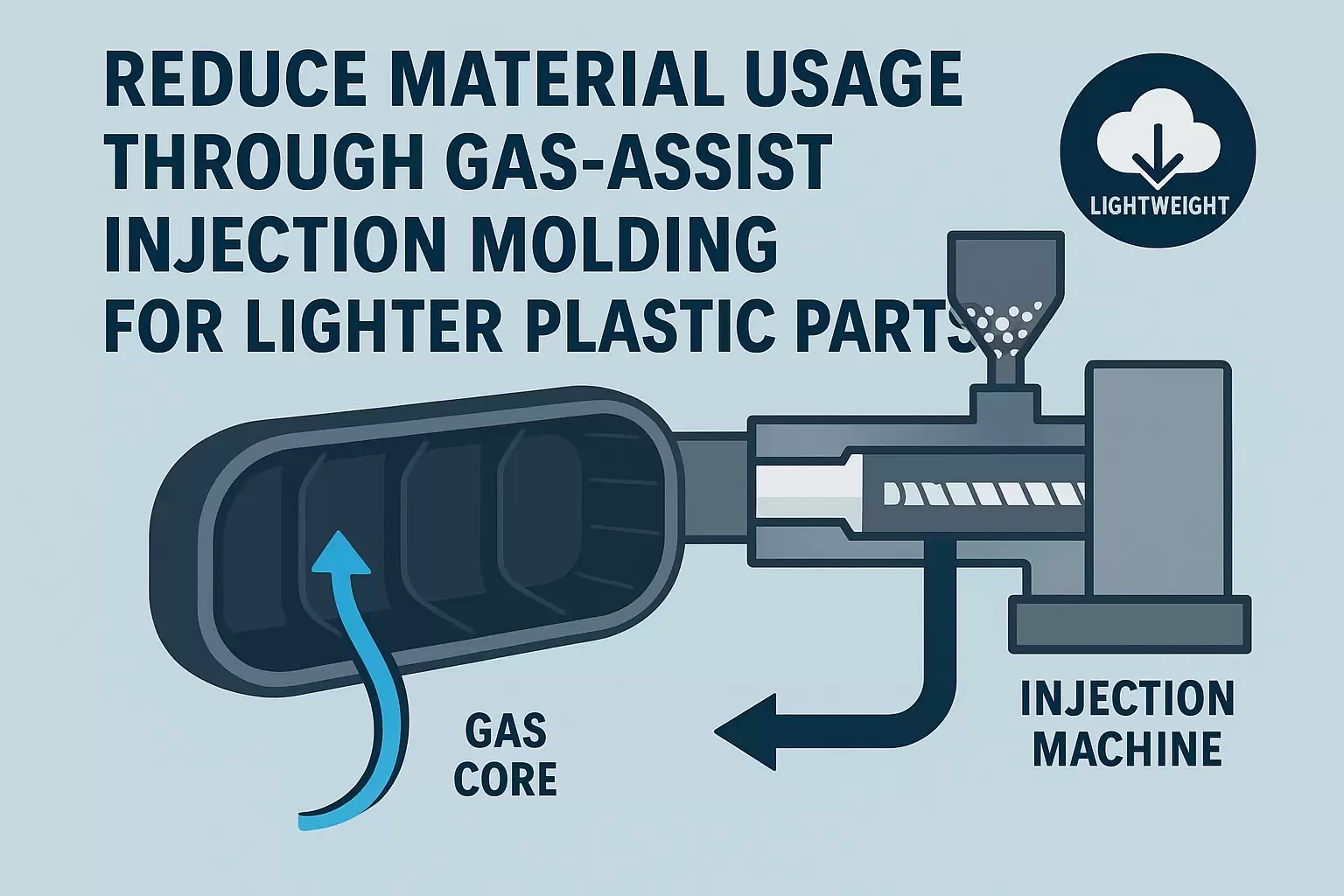

1 How Gas-Assist Works (in 60 Seconds)

-

Short-Shot Filling The mold is 60-90 % filled with molten plastic.

-

Inert Gas Injection Nitrogen flows through pre-designed gas channels or a hollow core pin.

-

Core-Out & Packing The gas front displaces the melt toward the cavity extremities, packing out sink and creating an internal hollow.

-

Cooling & Gas Venting After partial cooling, the gas pressure is released or vented; parts eject with a thick, glossy skin and a hollow backbone.

2 Key Benefits You Can Quantify

| Benefit | Typical Reduction vs. Solid Molding | Why It Matters |

|---|---|---|

| Resin Weight | 10–40 % | Lower BOM cost, greener footprint |

| Cycle Time | 15–30 % | Less cooling mass and faster packing |

| Clamp Tonnage | 20–40 % | Enables use of smaller presses |

| Warp & Sink | Near-zero on ribs & bosses | Fewer cosmetic rejects |

| Part Stiffness-to-Weight | +20–50 % | Ideal for long spans (trim panels, handles) |

3 Design Guidelines for GAIM Success

| Feature | Best Practice | Typical Dimension / Rule |

|---|---|---|

| Wall Thickness | Uniform outer skin | 2.5–4 mm for ABS/PC; down to 2 mm for PP |

| Gas Channel | Integrate along neutral axis | Ø 4–12 mm, 70–90 % of wall height |

| Ribs & Bosses | Attach to gas channel for sink-free support | Thickness 0.6× wall; boss core to touch channel |

| Corners & Turns | Radii ≥ 2× wall to keep gas flow laminar | Prevents blow-through or hesitation |

| Gates | Hot runner or edge gate opposite vent | Avoids gas escape at gate area |

| Venting | Dedicated gas pin or valve | Releases residual pressure before eject |

4 Process Window Highlights

| Parameter | Typical Range | Effect |

|---|---|---|

| Gas Pressure | 70–180 bar | Forms cavity core; too low → short fill, too high → blow-through |

| Gas Delay Time | 0.1–2.0 s after injection | Balances skin freeze vs. void quality |

| Polymer Melt Temp | Standard grade +10 °C | Improves flow before gas penetration |

| Mold Temp | Slightly higher than solid process | Promotes smooth inner cavity surface |

| Gas Hold Time | 4–12 s | Maintains pack until gate freeze |

5 Cost & Weight Reduction Snapshot

Part: ABS/PC TV Back Cover, 780 g solid

Annual Volume: 250 000 pcs

| Scenario | Weight (g) | Cycle Time (s) | Resin Cost/pc* | Annual Resin Savings |

|---|---|---|---|---|

| Solid | 780 | 45 | US $1.86 | — |

| GAIM | 540 (-31 %) | 35 (-22 %) | US $1.29 | US $142 k |

*Resin @ US $2.40 /kg. Additional nitrogen cost ≈ US $0.03 /pc—still yielding a 23 % cost drop.

6 Ideal Applications

-

Large, A-Class Panels – Automotive fender liners, appliance doors, kiosk housings

-

Long Structural Members – Furniture beams, lawn-equipment handles, treadmill rails

-

Thick-Rib Components – TV backs, game-console shells, instrument clusters

-

Hybrid Metal-Plastic Frames – Drone arms, medical carts, power-tool housings

7 When GAIM Is Not the Best Fit

| Limitation | Alternative |

|---|---|

| Ultra-thin ≤ 1.5 mm walls | MuCell micro-foaming or solid molding |

| Tiny, intricate parts | Standard molding or micro-cellular foaming |

| Parts requiring full solid interior (e.g., threads through thickness) | Partial GAIM or localized coring |

8 Why TaiwanMoldMaker.com for Gas-Assist Projects?

-

GAIM-Ready Tool Shops Experience with gas pins, shut-off valves, and multi-zone gas sequencing.

-

On-Site Nitrogen Generation Lower per-shot gas cost and tighter pressure control.

-

Simulation Expertise Moldex3D / Moldflow GAIM modules predict gas front, void size, and warp before steel cut.

-

Bridge-to-Mass Framework Prototype aluminum tools validated in 2–3 weeks; credit toward hardened production molds.

-

Integrated Secondary Ops Over-molding, paint, laser etch, and EMI shield under the same roof.

9 Action Plan—Launch Your Light-Weight Initiative

-

Select Candidate Part(s) – High material cost or sink-prone ribs? Perfect GAIM targets.

-

Send CAD & CTQ List to TaiwanMoldMaker.com for a 48-hour GAIM DFM + cost model.

-

Approve Tool Concept – Gas channel routes, gate design, and venting strategy.

-

Prototype & Validate – 100–300 trial parts: weight, drop-test, and cosmetic review.

-

Lock Process Window – Install cavity pressure + gas pressure sensors for repeatability.

-

Scale & Monitor – Monthly OEE + material-usage audits; continuous weight-reduction Kaizen.

Ready to Cut Resin and Costs?

Upload your 3-D files to TaiwanMoldMaker.com and discover how gas-assist injection molding can trim weight, improve aesthetics, and boost profit—without compromising strength or timeline.

SEO Title (≤ 60 chars)

Gas-Assist Injection Molding: Lighter Parts, Lower Cost

Meta Description (≤ 150 chars)

Learn how gas-assist injection molding reduces resin usage by up to 40 %—get design tips, cost data, and expert help from TaiwanMoldMaker.com.