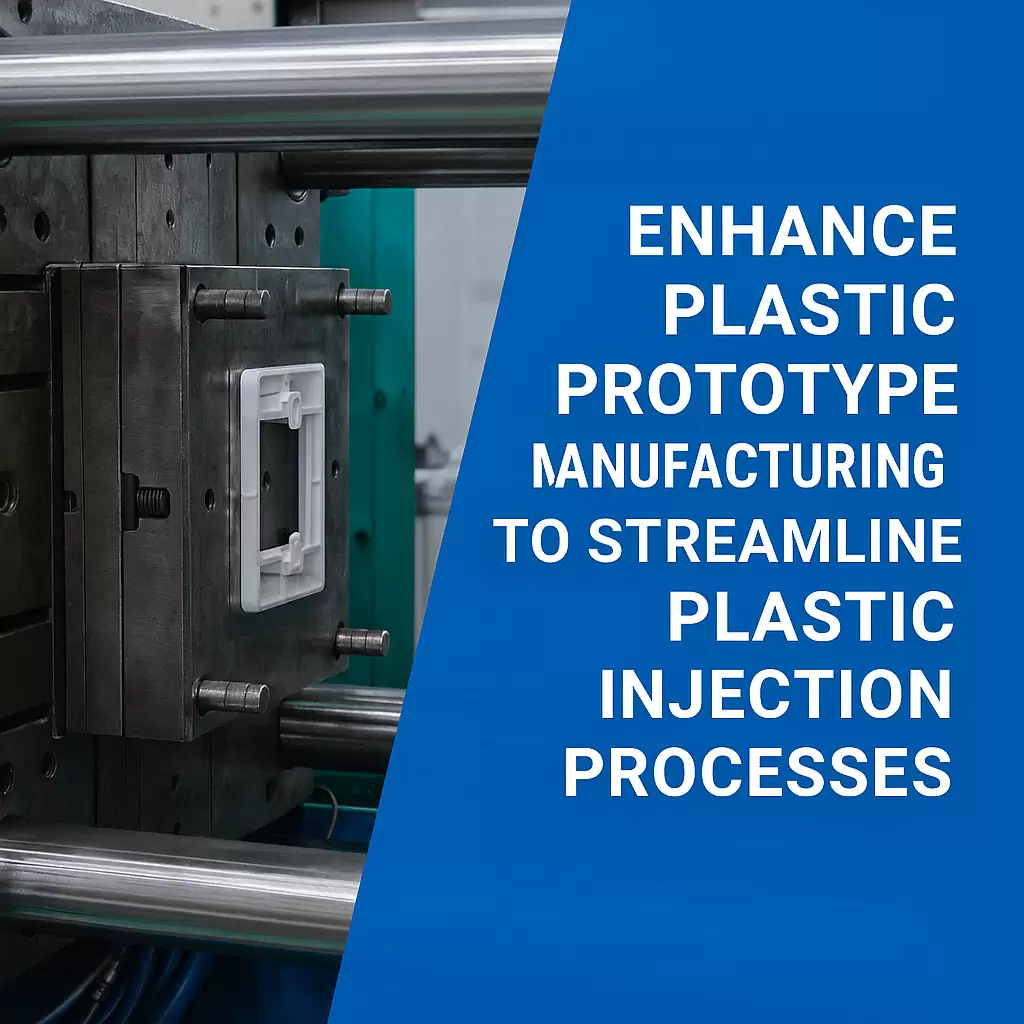

Enhance Plastic Prototype Manufacturing to Streamline Plastic Injection Processes

Enhance Plastic Prototype Manufacturing to Streamline Plastic Injection Processes

In the competitive world of product development, efficient plastic prototype manufacturing is key to reducing time-to-market and minimizing costly production errors. By refining the prototyping phase, businesses can significantly improve the quality and performance of their final plastic injection molded parts. At INTERTECH (https://www.taiwanmoldmaker.com), we specialize in helping clients enhance every stage of their manufacturing journey—starting with a smarter, faster prototyping approach.

Why Plastic Prototype Manufacturing Matters

A prototype serves as the foundation for validating part design, testing fit and function, and identifying manufacturability issues early. A well-executed prototype reduces:

-

Tooling rework

-

Design flaws

-

Production delays

Most importantly, it ensures that the final product aligns with both technical requirements and market expectations.

Key Benefits of Enhanced Prototyping in Injection Molding

1. Accelerates Design Validation

Rapid prototyping allows engineering teams to quickly assess how a part performs under real-world conditions. By iterating faster, they can optimize:

-

Wall thickness

-

Draft angles

-

Material flow

-

Assembly compatibility

2. Reduces Tooling Costs and Delays

Identifying design flaws before tooling fabrication reduces the risk of expensive rework. With a validated prototype, mold design becomes more accurate and efficient.

3. Supports Better Communication

Physical prototypes help align stakeholders—engineers, marketing teams, and investors—by providing a tangible model for discussion and decision-making.

4. Optimizes Material Selection

Through prototype testing, manufacturers can evaluate how different plastics behave under specific load, thermal, or environmental conditions.

Prototyping Techniques That Streamline Injection Molding

CNC Machining

Ideal for high-precision, functional prototypes that closely mimic injection-molded parts.

3D Printing (Additive Manufacturing)

Perfect for rapid, cost-effective concept validation and early-stage design feedback.

Soft Tooling / Aluminum Molds

A bridge between prototyping and production that enables small batch runs for real-world testing before full-scale manufacturing.

How INTERTECH Enhances Prototype-to-Production Transitions

At INTERTECH, we don’t just build molds—we partner with clients from concept to commercial success. Our plastic prototype manufacturing services include:

-

Collaborative DFM support

-

3D modeling and mold flow simulation

-

Functional prototypes using CNC or 3D printing

-

Low-volume soft tooling for testing

-

Seamless hand-off to full production with ISO-certified quality standards

Explore our custom molding solutions and tooling process to see how we bring ideas to life.

Applications Across Industries

Our enhanced prototyping approach supports innovation in:

-

Automotive components

-

Medical devices

-

Electronic enclosures

-

Industrial tooling

-

Consumer product development

Whether you need a proof of concept or a production-ready test batch, INTERTECH provides the speed and accuracy you need to stay ahead.

Conclusion

Upgrading your plastic prototype manufacturing process is one of the most effective ways to streamline plastic injection molding and reduce time-to-market. By partnering with a knowledgeable and experienced team like INTERTECH, you can improve part performance, reduce development costs, and ensure a smoother transition to mass production.

Start your prototype-to-production journey today. Contact INTERTECH: https://www.taiwanmoldmaker.com/contact