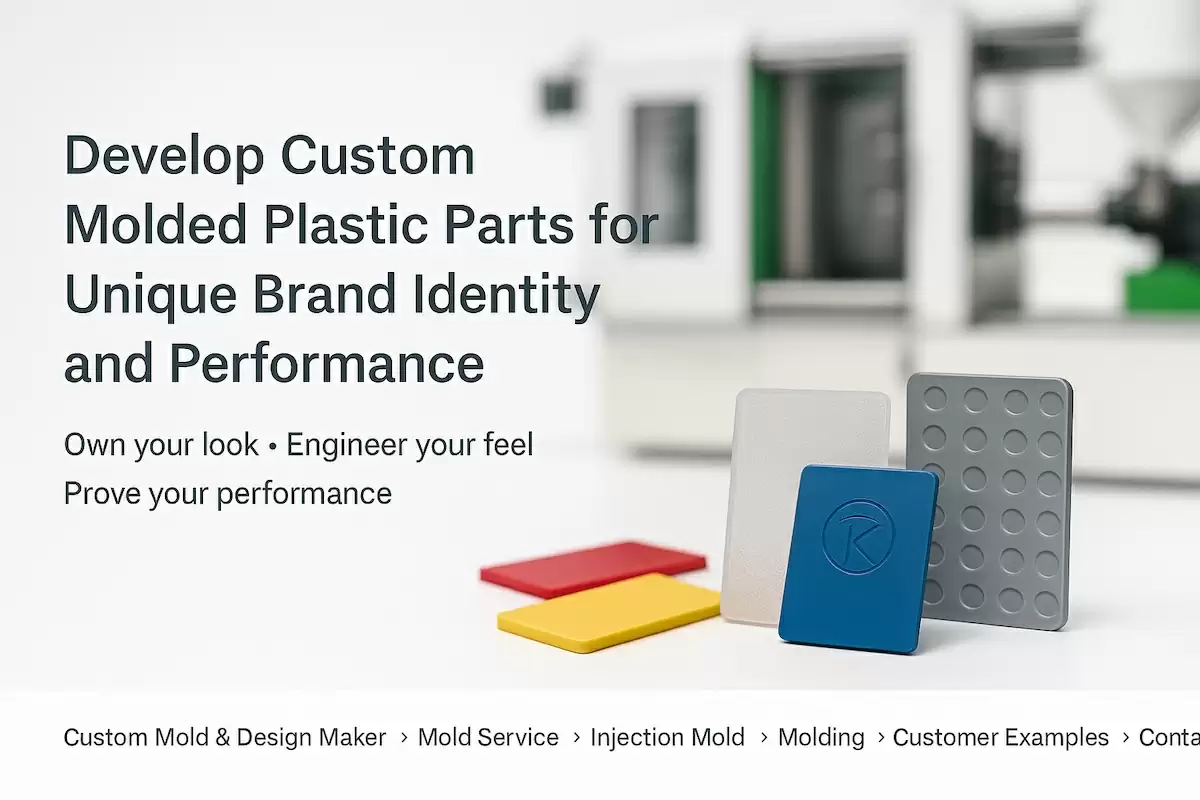

Develop Custom Molded Plastic Parts for Unique Brand Identity and Performance

Develop Custom Molded Plastic Parts for Unique Brand Identity and Performance

Develop Custom Molded Plastic Parts for Unique Brand Identity and Performance

Own your look • Engineer your feel • Prove your performance

Great products don’t just work—they look, feel, and last like your brand promises. With the TaiwanMoldMaker.com network, you can turn brand strategy into production-ready plastic parts that ship on time and on spec.

Explore our end-to-end services:

Custom Mold & Design Maker → Mold Service → Injection Mold → Molding → Customer Examples → Contact

Brand identity, designed into the part

-

Signature surfaces: SPI/Mold-Tech textures, laser micro-textures, gloss-control, soft-touch overmold.

-

Colour that matches standards: Custom masterbatch to Pantone/RAL with ΔE tolerances and aging targets.

-

Logo & patterns: Steel-in relief/emboss, insert coins, laser mark, or IMD/IML for scratch-resistant graphics.

-

Lighting & optics: Light-pipes, halo rings, brand-colour LEDs, and diffusion control for consistent luminance.

-

Touch & sound: Tactile ribs/knurls, detent feel, hinge torque, and controlled acoustic “clicks” for UX.

Performance that’s engineered—not guessed

-

Structural integrity: Ribs/bosses, living hinges, fibre-reinforced resins, FEA-informed wall schemes.

-

Environment & durability: UV/chemical/sweat resistance, abrasion class, IP dust/water ratings.

-

Thermal & electrical: Flame ratings (UL 94), CTI, dielectric spacing, heat-deflection/creep.

-

Fit & finish at scale: GD&T on CTQs, warpage control, cavity pressure monitoring for first-time-right builds.

Material quick-guide (brand × performance)

| Goal | Go-to options | Notes |

|---|---|---|

| Premium clarity & toughness | PC, COC/COP | Add UV/impact grades; polish optics to spec. |

| Stiff + paint-free cosmetics | ABS, PC-ABS | Texture + colour masterbatch for paint elimination. |

| Wear/low friction | POM (Acetal), PA + lubricated grades | Great for mechanisms, clips, latches. |

| Outdoor/UV & chemical | ASA, PA12, ETFE/PVDF | For harsh environments and chemicals. |

| Soft-touch or sealing | TPE/TPU (overmold) | Design mechanical locks for peel resistance. |

We recommend grade selection after environment/regs/colour testing.

DFM rules that protect brand & cost

-

Hide parting lines and gate vestiges behind logos/trim; plan ejector patterns off cosmetic zones.

-

Texture-aware draft: +1.5–3.0° on grained areas; set relief depths for crisp logos after etch.

-

Uniform walls (1.5–3.0 mm) to avoid sink/warp; use ribs instead of bulk.

-

Bosses & inserts: Standardise diameters/stand-offs; specify threaded brass/steel inserts where needed.

-

Tolerances: Lock datums with GD&T; reserve post-machining for microns-level features only.

Tooling & process strategy

-

Bridge tools → steel: Start fast with aluminium/MUD; scale via copy-cavity steel when demand lands.

-

Two-shot / overmold: Hard–soft, colour-split, or light-pipe integration for premium UX.

-

IMD/IML: Graphics under a hardcoat film for long-life cosmetics.

-

Scientific molding: V/P by pressure, cavity sensors, gate-freeze, and DOE to lock the golden recipe.

-

MES visibility: OEE, CpK, scrap, kWh/kg, genealogy—shareable for remote audits.

Validation & brand quality checks

-

Colour & gloss: ΔE/Gloss targets over aging (UV/heat/chemicals).

-

Surface durability: Taber abrasion, scratch/chemical wipe, sweat/oil tests.

-

Functional tests: Drop/torsion, latch life, IP ingress, noise/vibration.

-

Metrology pack: FAIR + CMM/scan, cosmetic map sign-off, and retain samples per revision.

Example timeline (pilot → ramp)

-

Day 0–2: 48-Hour DFM (flow/cool/warp, texture plan, risk log) → approve

-

Day 3–10: Tool build (Al/MUD) + texture/polish; colour masterbatch trial

-

Day 11–13: T0 in production resin; weight ladder + gate freeze; cosmetic tune

-

Day 14–15: T1 + FAIR + metrology; colour/gloss/ΔE report; ship FA parts

-

Day 16+: Copy-cavity proposal; optional two-shot/IMD upgrade for launch edition

Steel first? Plan Day 3–20/28 depending on cavitation/IMD/two-shot complexity.

RFQ checklist (copy/paste; it prevents rework)

-

Target T1/SOP dates and must-hit milestones.

-

Brand specs: Colour standard (Pantone/RAL), ΔE target, texture code (SPI/Mold-Tech), logo method.

-

CAD (STEP/IGES) + 2D with CTQs/GD&T; cosmetic map & gate/parting preferences.

-

Material options (UV/FR/food/medical/chemical), finish (paintless vs paint/coating).

-

Tooling plan: MUD/Al or steel; cavitation; slides/hand-loads; two-shot/overmold/IMD/IML.

-

Quality & tests: FAIR, CMM/scan, CpK targets; colour/gloss/aging, IP/impact/abrasion as needed.

-

Packaging & logistics: Label/brand standards, export pack, Incoterms; FA courier path.

-

Data access: MES dashboards (OEE, CpK, scrap, kWh/kg), lot genealogy.

Send your package here → Contact

Why TaiwanMoldMaker.com

-

One accountable owner from DFM to SOP—brand, engineering, and operations aligned.

-

Standardised, robot-ready cells and cosmetic-class tooling partners.

-

Audit-ready documentation so stakeholders approve quickly.

Start here:

Custom Mold & Design Maker → Mold Service → Injection Mold → Molding → Customer Examples → Contact