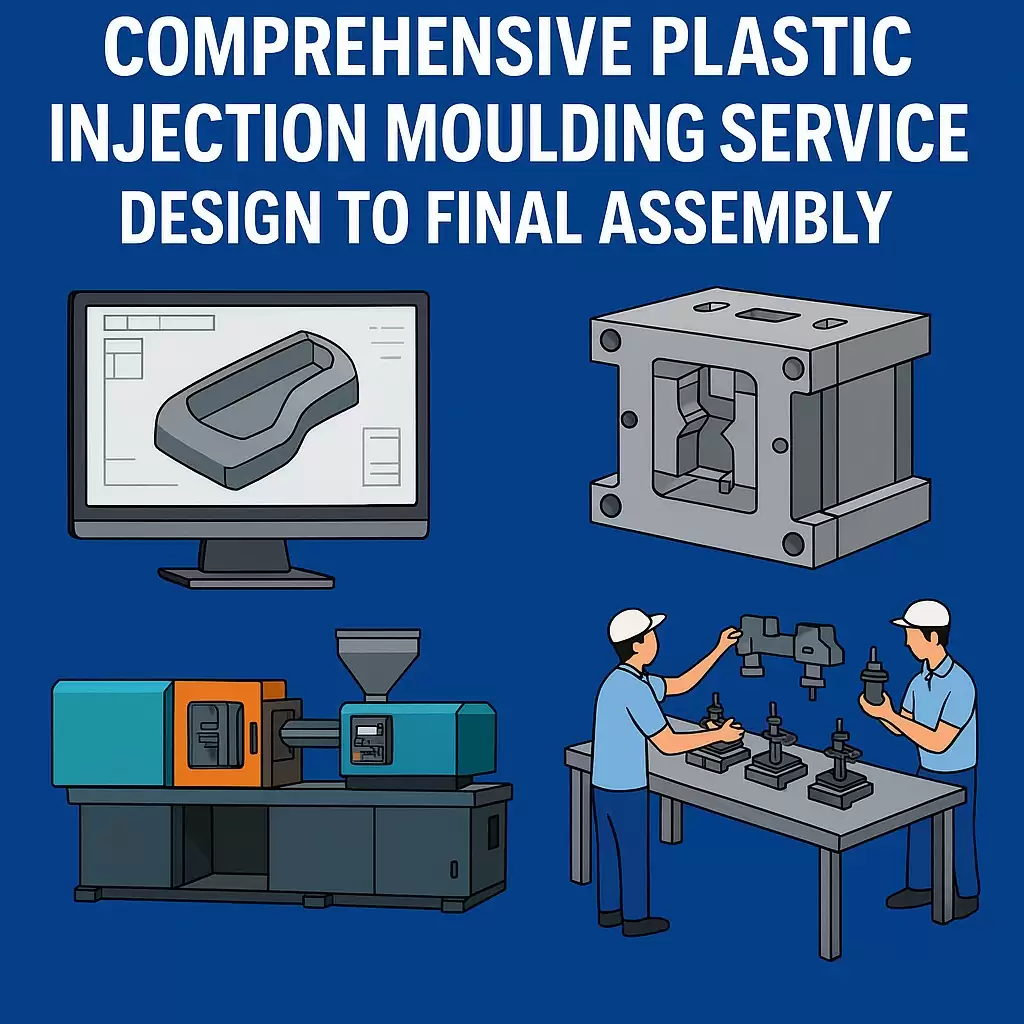

Access a Comprehensive Plastic-Injection-Moulding Service—From Design to Final Assembly

Access a Comprehensive Plastic-Injection-Moulding Service—From Design to Final Assembly

Launching a plastic product involves far more than cutting a tool and pressing “start.” Each phase—from the first CAD sketch to retail-ready packaging—carries its own technical pitfalls, regulatory hurdles, and cost drivers. TaiwanMoldMaker.com brings every critical step under one expertly managed roof, giving overseas buyers a predictable timeline, transparent costing, and iron-clad quality assurance.

1 Concept & Design-for-Manufacture (DFM)

Goal: Lock geometry, tolerances, and material choices before steel is cut.

| What Happens | How We Add Value |

|---|---|

| 48-hour CAD review, draft analysis, and gate layout | Live DFM session with tool designers and your engineering team |

| Moldflow® and warpage simulation | Catch knit lines and cooling hotspots early |

| Resin & additive selection | PC, POM, TPE, PCR blends, medical-grade LSR—all validated for flow and compliance |

Explore: Custom Mold and Design Maker—concept sketches through digital twins.

2 Tooling & Process Engineering

Goal: Build a robust, maintainable mold matched to forecast volumes.

| Option | Typical Use | Lead Time* |

|---|---|---|

| Aluminum bridge tool | EVT/DVT, ≤ 25 k shots | 2-3 weeks |

| P20 family mold | 50–250 k shots, mixed SKUs | 4–5 weeks |

| H13/S136 hot-runner | 1 M+ shots, automotive & medical | 6–7 weeks |

*From PO to T-0 parts; includes steel, machining, EDM, and bench fitting.

Explore: Mold Service—DFM, steel selection, FAT, and PPAP in one workflow.

3 Precision Injection Moulding

| Capability | Benefit to Buyers |

|---|---|

| 60 t – 3 000 t electric & servo-hydraulic presses | Micron-scale micro parts and 1-meter panels in a single plant network |

| Scientific-moulding recipes & cavity-pressure sensors | CpK ≥ 1.67 by the first eight-hour shift |

| 24/7 MES dashboard | Live OEE, scrap, and OTIF data in your browser |

Explore: Injection Mold—high-cavity, hot-runner systems built for speed.

4 Advanced Materials & Multi-Shot Solutions

-

Two-shot rotary and index-plate tools for seamless colour breaks

-

Overmoulded TPE grips and IP67 gaskets in a single clamp cycle

-

Class-VI Liquid Silicone Rubber Molds for wearables and baby care

-

Flexible Silicone Molds for pilot runs and rapid iterations

5 Integrated Secondary Operations

| Process | Typical Use | In-Line Advantage |

|---|---|---|

| Pad-printing & UV-cure paint | Logos, indicators | Zero freight legs |

| Ultrasonic welding & threaded insert-moulding | Sealed housings | One PO, one SPC plan |

| CNC trimming & leak testing | Tight tolerance vents | CpK data tied to each cavity ID |

| Metal Stamping | Hybrid plastic-metal assemblies | Eliminates outside vendors |

6 Final Assembly, Kitting & Logistics

-

Clean-room or white-room assembly lines for medical and consumer electronics

-

Automated torque stations, vision SPC, and electronic lot traceability

-

On-site packaging, bar-coding, and pallet optimisation for sea or air freight

-

Drop-ship programs direct to 3PLs or Amazon FBA hubs

Explore: Molding—from pilot batches to millions of parts per year.

7 Proof of Performance

See how global OEMs in automotive, medical, and IoT sectors reduced launch time by up to 40 % and scrap by 60 %:

8 Your Fast-Track Engagement Roadmap

-

Upload native CAD & volume forecast—STEP, IGES, or SolidWorks.

-

Receive a 48-hour DFM & cost pack—including Moldflow and timeline.

-

Approve dual-path quote—bridge tool plus steel production tool.

-

Get T-0 parts in as little as three weeks—ready for lab, field, or retail tests.

-

Scale seamlessly—hot-runner optimisation, in-line finishing, final assembly, and global drop-ship.

Final Takeaway

A truly comprehensive plastic-injection-moulding service doesn’t just make parts—it de-risks your entire product-launch journey. Partner with TaiwanMoldMaker.com to unify design, tooling, moulding, finishing, and assembly under one accountable, data-transparent network—and hit every milestone with confidence.