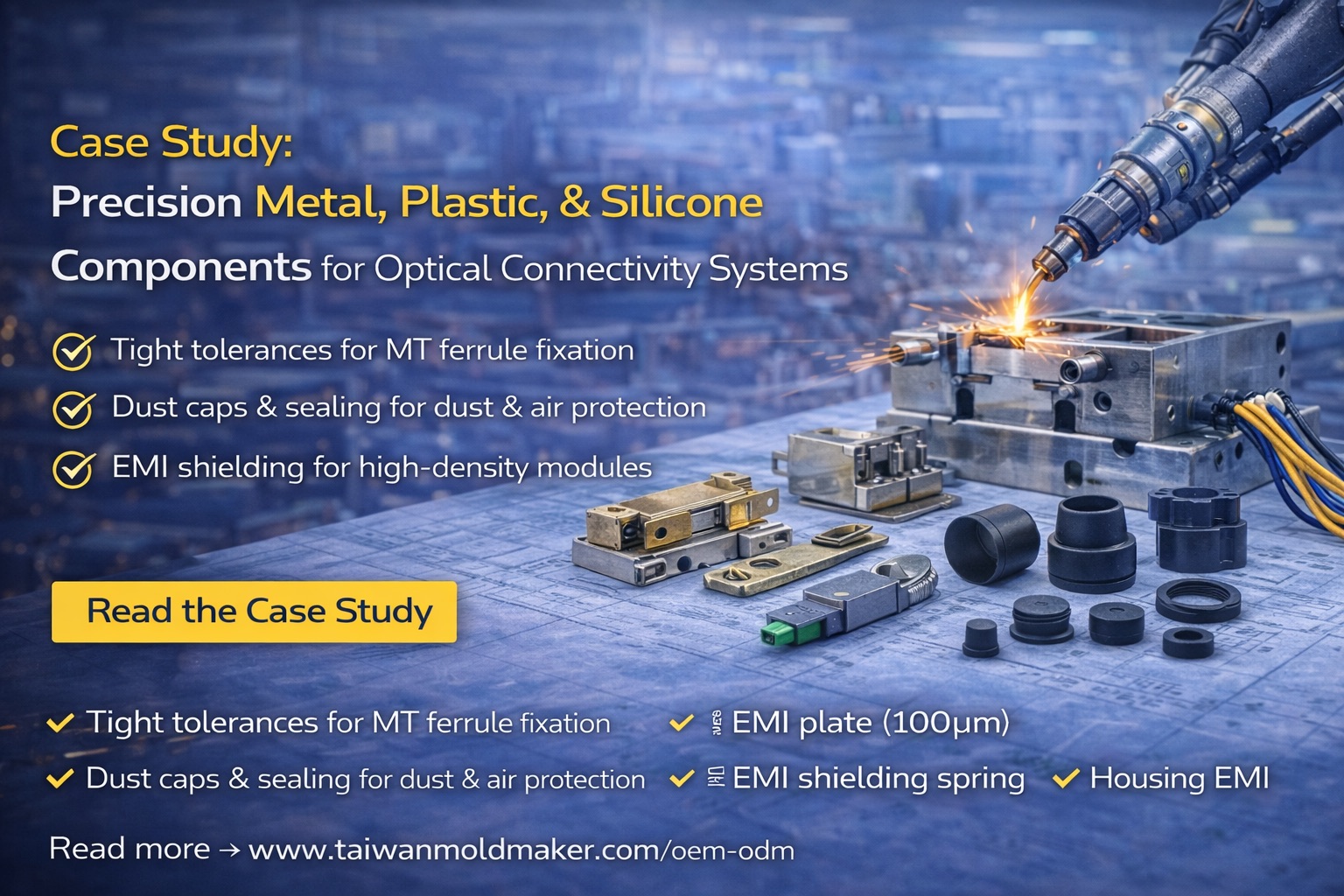

Case Study: Precision Metal, Plastic, and Silicone Components for Optical Connectivity Systems

Case Study: Precision Metal, Plastic, and Silicone Components for Optical Connectivity Systems

Case Study: Precision Metal, Plastic, and Silicone Components for Optical Connectivity Systems

Project Background

A Europe-based industrial connectivity and optical interconnect solutions provider required a long-term manufacturing partner capable of producing high-precision metal, plastic, and silicone components for use in fiber-optic and MT-based connector systems.

The customer faced several challenges:

-

Tight dimensional tolerances for MT ferrule–related components

-

Mixed-material production (metal, plastic, and silicone) under one supply chain

-

Stable quality for high-volume production

-

Reliable export capability for global deployment

INTERTECH was selected as the manufacturing partner due to our integrated tooling, injection molding, metal processing capabilities, and proven OEM experience.

Manufactured Components Overview

Precision Metal Components

INTERTECH manufactured a range of metal parts used for mechanical fixation, electromagnetic shielding, and structural stability within optical connector assemblies.

Ferrule Fixation & Clamping Components

-

Metal ferrule fixation

-

MT ferrule fixation

-

Ferrule clamp

-

Metal ferrule clamp

-

MT ferrule clamp

-

OBT MT ferrule clamp

These components require high concentricity, consistent clamping force, and surface integrity, ensuring precise fiber alignment and long-term mechanical reliability.

EMI Shielding Components

-

EMI plate (100 μm)

-

EMI shielding spring

-

EMI shielding plate

-

Housing EMI shielding plate

-

Housing EMI shielding spring

All EMI components were produced to meet electromagnetic interference suppression requirements, supporting stable signal transmission in high-density optical modules.

???? Learn more about our metal component manufacturing & tooling support

https://www.taiwanmoldmaker.com/oem-odm

Silicone & Elastomer Components

To support environmental sealing and vibration resistance, INTERTECH produced multiple silicone rubber components with strict material and dimensional control.

Sealing & Air Management Parts

-

Sealing ring

-

OBT sealing ring

-

Air sealing

-

Air sealing ring

These parts were designed to provide:

-

Dust and moisture protection

-

Stable elasticity across temperature ranges

-

Long service life under repeated assembly cycles

???? Explore our custom molding and material engineering services

https://www.taiwanmoldmaker.com/plastic-injection-molding

Plastic Injection Molded Components

INTERTECH also supplied precision plastic parts used for protection, transport, and system integration.

Protective & Functional Plastic Parts

-

Dust cap

-

OBT dust cap

-

Dust cover cap

-

Transport cap

-

OBT transport cap

-

Air connector

These components were produced using custom injection molds to ensure:

-

Snap-fit accuracy

-

Consistent wall thickness

-

Reliable performance during shipping and field installation

???? Learn more about our mold design & injection molding capabilities

https://www.taiwanmoldmaker.com/mold-design

Manufacturing Challenges & INTERTECH Solutions

1. Multi-Material Integration

The project required metal stamping/machining, plastic injection molding, and silicone molding under one coordinated production system.

INTERTECH reduced supply chain complexity by managing all processes internally.

2. Tight Tolerance & Quality Stability

Ferrule-related components demand micron-level consistency.

Our engineering team implemented process control, tooling optimization, and in-process inspection to ensure repeatable quality across production batches.

3. Export-Ready Production

All components were produced with export compliance, traceability, and packaging control, supporting smooth international logistics.

Results & Customer Outcomes

-

Stable, long-term OEM production

-

Reduced supplier coordination risk

-

Consistent product performance across global deployments

-

Scalable manufacturing capacity for future programs

INTERTECH continues to support this customer as a trusted OEM manufacturing partner for optical connectivity components.

Why OEM Buyers Choose INTERTECH

-

Integrated metal + plastic + silicone manufacturing

-

Custom tooling and mold development

-

Export-focused production experience

-

Proven track record in electronics and connectivity components

???? Discover our OEM / ODM manufacturing services

https://www.taiwanmoldmaker.com/oem-odm

???? Contact our engineering team

https://www.taiwanmoldmaker.com/contact

Looking for a Reliable OEM Partner?

If your project requires precision metal parts, plastic injection molded components, or silicone sealing solutions for optical, electronic, or industrial applications, INTERTECH is ready to support your program—confidentially and professionally.