Integrate co injection molding for innovative multi-layer plastic part development

Integrate co injection molding for innovative multi-layer plastic part development

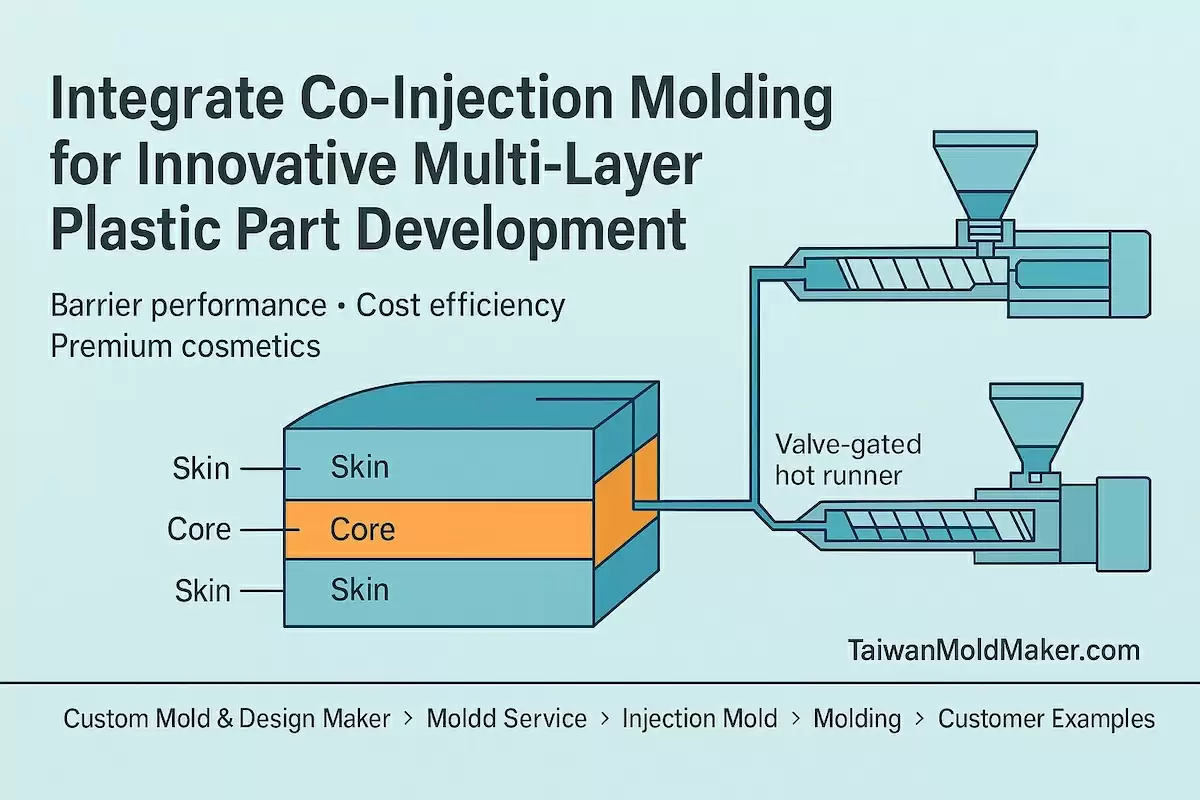

Integrate Co-Injection Molding for Innovative Multi-Layer Plastic Part Development

Barrier performance • Cost efficiency • Premium cosmetics

Looking to add barrier, recycled cores, or specialty surfaces without secondary assembly? Co-injection molding (a.k.a. sandwich molding) builds multi-layer parts in one shot—placing a skin material around a core (or skin–core–skin) using a shared mold and specialized hot-runner sequencing. With the TaiwanMoldMaker.com network, you can turn advanced material stacks into production-ready parts—on time, on spec.

Explore our end-to-end services:

Custom Mold & Design Maker → Mold Service → Injection Mold → Molding → Customer Examples → Contact

What co-injection molding is (and isn’t)

-

Co-injection (sandwich): Two materials are injected through the same gate with timed/sequenced flow so the skin encapsulates the core. Ideal for barrier layers, recycled cores, stiffness tuning, and cost reduction.

-

Two-shot / overmolding: Different materials in separate shots/cavities to create distinct visible features or soft-touch zones. Choose this for grips, seals, colour splits, or mechanical locks.

If you want a hidden barrier or recycled core with a premium outer surface, co-injection is the right tool.

Common layer stacks & goals

| Stack | Typical Materials | Why it works |

|---|---|---|

| Skin / Core | PP skin / Regrind PP core | Cut resin cost, keep Class-A exterior. |

| Skin / Barrier / Skin | PP / EVOH / PP | Food/chemical barrier for containers, caps, valves. |

| UV/chem-resistant skin / Tough core | ASA or PVDF skin / PC-ABS, PA core | Outdoor parts: weatherable outer, tough inside. |

| Clear skin / Diffusive core | PMMA or PC skin / light-diffusing core | Lighting lenses & light-pipes with controlled luminance. |

| Wear skin / Damping core | POM skin / TPE or PP core | Low-friction surface with NVH damping. |

We help you select grades for adhesion, shrink match, and regulatory requirements (UL, food, medical).

Applications that benefit most

-

Food & lab containers, valves, closures: EVOH/PA barriers for OTR/WVTR targets.

-

Consumer housings & appliance panels: Cosmetic skins over regrind cores to reduce cost & footprint.

-

Outdoor/industrial: UV/chemical-resistant skins (ASA, PVDF) with tough cores (PC-ABS, PA).

-

Lighting & optics: Clear skins with diffusive cores for uniform light and hidden welds.

-

Automotive & tools: Wear-resistant skins with reinforced cores for stiffness + durability.

Tooling & process: how we control the layers

-

Hot-runner & nozzles: Co-injection manifolds or dual-shot valve gating with precise sequencing to establish skin, then core.

-

Skin/core ratio: Typically 10–70% core by volume; tune via velocity/pressure transfer and time.

-

Thermal balance: Cooling layout designed for differential shrink; conformal-cooled inserts near heavy features.

-

Sensors & controls: Cavity-pressure sensors, sequential valve timing, gate-freeze studies to lock penetration depth.

-

Maintainability: Standardized heaters/TCs, doweled sub-inserts, and spare kits for uptime.

DFM rules for co-injection

-

Uniform walls (1.8–3.0 mm) wherever possible; ribs over mass to control core “break-through.”

-

Knit-line management: Place away from view; move to masked areas with parting line strategy.

-

Draft & radii: ≥1–2° draft; generous radii to stabilize skin thickness and ejection.

-

Adhesion & shrink match: Pair materials with compatible surface energies and comparable shrinkage to prevent telegraphing/warpage.

-

Colour show-through: Use skin thickness and pigment loading to hide darker cores.

Quality verification for multi-layer parts

-

Sectioning & microscopy: Microtome cross-sections for skin/core thickness and uniformity.

-

Spectroscopy/mapping: FTIR/EDS/DSC for barrier identification and distribution.

-

Functional tests: OTR/WVTR, burst/leak for containers; impact, abrasion, UV/chemical for housings.

-

Dimensional & cosmetic: FAIR + CMM/scan; gloss/ΔE; visual acceptance with viewing-zone maps.

Example timeline (pilot → ramp)

-

Day 0–2: 48-Hour DFM Pack (flow/cool/warp, skin/core ratio model, risk log) → alignment call

-

Day 3–12: Tool build (Al/MUD or pre-hard steel) + co-injection hot-runner setup; EOAT/fixtures in parallel

-

Day 13–15: T0 trials: skin-only → core penetration tuning; gate-freeze & cavity balance

-

Day 16–18: T1 + FAIR + sectioning/optical/barrier tests; DOE window set; ship FA parts

-

Day 19+: Copy-cavity proposal; barrier validation or recyclate percentage study for ramp

(Steel-first or large multi-cavity tools: ~20–28 days to T0 depending on geometry & finish.)

Cost & sustainability advantages

-

Resin savings: Hide regrind or recycled material in the core while protecting exterior cosmetics.

-

Fewer operations: Barrier or specialty layers achieved in-mold—no laminations or coatings.

-

ESG metrics: Track kWh/kg and recycled content via MES; documented for compliance reporting.

RFQ checklist (copy/paste—prevents rework)

-

Target T1/SOP dates and milestone gates (DFM, T0, T1).

-

CAD (STEP/IGES) + 2D with CTQs/GD&T; cosmetic/viewing zone map.

-

Skin & core materials (alternates OK): colour, UV/FR/food/medical needs; barrier targets (OTR/WVTR).

-

Skin/core ratio goal and areas where ratio must be held tightly.

-

Tooling plan: MUD/Al vs steel, cavitation, valve sequence, conformal-cooling candidates.

-

Validation scope: Sectioning, FTIR/DSC, OTR/WVTR (if barrier), DOE, FAIR, CMM/scan, CpK targets.

-

Automation & tests: EOAT take-out; leak/occlusion/burst; vision SPC.

-

Data access: MES dashboards (OEE, CpK, scrap, kWh/kg, genealogy).

-

Packaging & logistics: Lot size, labels, export packing, Incoterms; FA courier path.

Send your package here → Contact

Why TaiwanMoldMaker.com for co-injection

-

Specialized hot-runner & sequencing expertise with proven skin/core stability.

-

Simulation-led DFM and scientific molding to lock ratios, cycles, and cosmetics fast.

-

Standardized, robot-ready cells with vision SPC and audit-ready MES data for remote approvals.

-

Bridge-to-scale path: Aluminium/MUD pilots → copy-cavity steel when demand lands.

Start here:

Injection Mold → Molding → Mold Service → Customer Examples → Contact