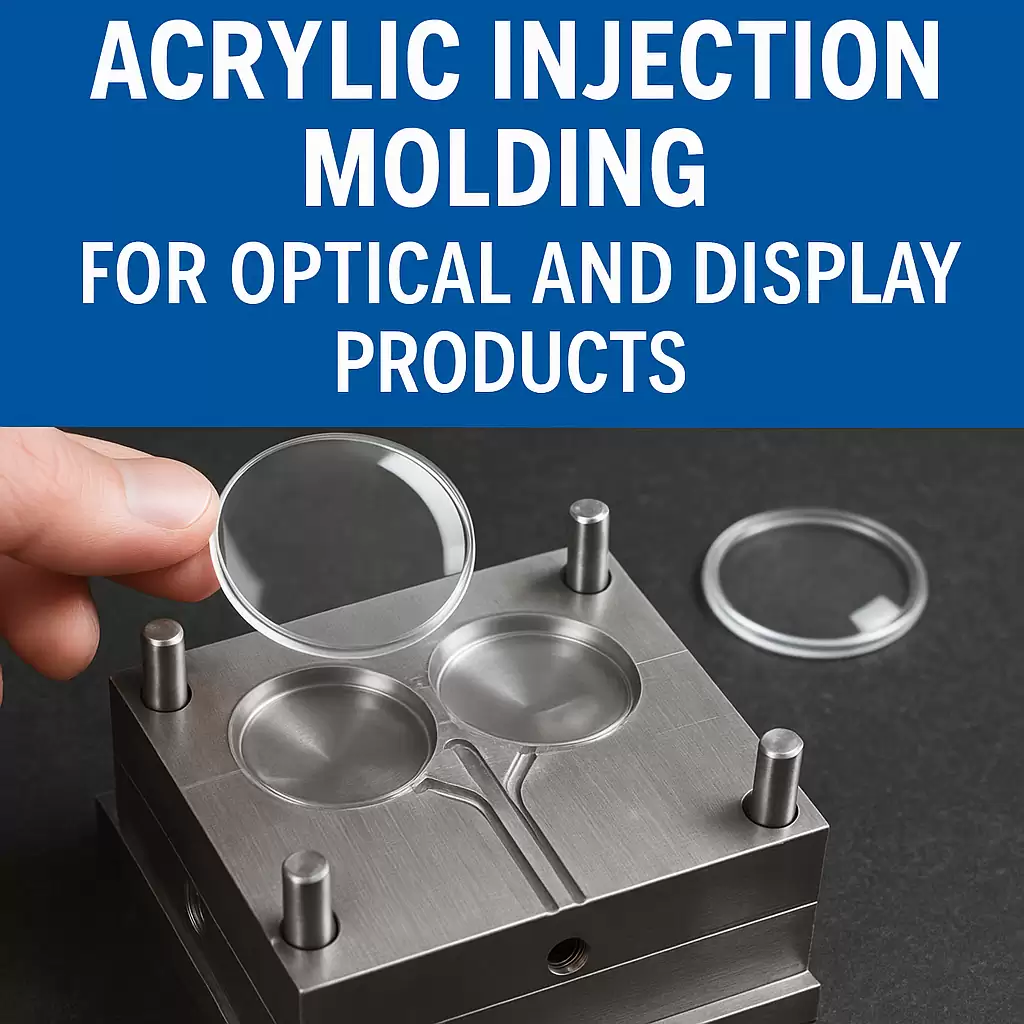

Improve Clarity with Acrylic Injection Molding for Optical and Display Products

Improve Clarity with Acrylic Injection Molding for Optical and Display Products

Few plastics rival acrylic (PMMA) when crystal-clear transparency, scratch resistance, and UV stability are non-negotiable. From light guides in automotive clusters to diffuser lenses in LED signage, precision acrylic injection molding converts polished steel cavities into optics-grade parts that rival glass while slashing weight and processing costs. Below is a practical blueprint for designers, buyers, and project managers who want to push optical performance to the limit—without production headaches.

1 Why Acrylic (PMMA) Outshines Other Transparent Resins

| Attribute | Acrylic (PMMA) | PC | PETG |

|---|---|---|---|

| Light Transmission (ASTM D1003) | 92 % (highest of any thermoplastic) | 88–90 % | 88–90 % |

| Refractive Index | 1.49 | 1.58 | 1.57 |

| UV Stability | Excellent (years with no yellowing) | Fair (needs UV stabilizers) | Poor |

| Scratch Resistance | Very good (≈ HB pencil) | Moderate | Low |

| Price (relative) | $ | $$ | $ |

Bottom line: Choose PC for impact-critical covers, but pick acrylic when clarity, gloss, and UV performance define product value.

2 Material Options to Elevate Optical Performance

-

High-Flow Grades – Low melt viscosity fills micro-features in Fresnel lenses and light-pipe ribs without weld lines.

-

Anti-Static PMMA – Dissipates surface charge in touchscreen covers, stopping dust attraction under showroom lighting.

-

Impact-Modified Acrylic (PMMA-ABS blends) – Retains 85 % of light transmission while boosting Izod impact 5-fold for hand-held VR lenses.

-

UV-Blocking Variants – Built-in absorbers protect edge-lit displays from yellow shift during outdoor use.

3 Mold Design & Process Parameters for Glass-Like Clarity

| Critical Area | Best Practice | Benefit |

|---|---|---|

| Steel Selection | Mirror-finish H13, NAK-80, or S136; Ra ≤ 0.05 µm | Transfers optical polish directly into part |

| Vent Depth | 0.015 – 0.02 mm near last-to-fill zones | Eliminates burn marks and silver streaks |

| Gate Style | Fan or film gates on non-optical edges | Minimizes shear whitening and weld lines |

| Melt Temperature | 220 – 260 °C (grade-specific) | Prevents splay while maintaining flow |

| Mold Temperature | 70 – 90 °C with precise water circuits | Slows skin freeze, raising surface gloss |

| Hold Pressure & Time | High/long enough to pack out sink—watch for birefringence | Maintains optical uniformity |

Tip: Polishing the cavity to SPI-A2 (Grade #2 diamond buff) is mandatory for display covers; using sub-A2 spikes scrap rates.

4 Design Guidelines for Optics-Grade Parts

-

Draft ≥ 0.5° per side on polished faces to release without drag marks.

-

Uniform Wall Thickness—keep within ± 15 % to avoid flow lines; adjust with ribs or bosses when stiffness is needed.

-

Rib Height ≤ 3× wall and thickness ≤ 0.5× wall to prevent sink visible through the lens.

-

Texturing Zones—matte only on frame flanges; keep optical pathways mirror-smooth.

-

Logo Deboss—place on non-critical edges and polish after EDM to remove EDM haze.

5 Secondary Finishes that Add Value

-

Hard-Coat Dip or Flow-Coat – Raises abrasion resistance to 3H-4H pencil hardness (automotive instrument clusters).

-

Vapor Deposition (AR/HC/ITO) – Adds anti-reflective layers or transparent conductivity for capacitive touch panels.

-

Laser Etching – Creates light marks on back-lit panels without dust from mechanical milling.

6 Quality Control: What to Measure and How

| Metric | Method | Acceptable Range (Display-Grade) |

|---|---|---|

| Luminous Transmittance | Spectrophotometer per ASTM D1003 | ≥ 91 % |

| Haze | ASTM D1003 | ≤ 1 % |

| Birefringence | Polarized light inspection | No color fringes in 20 cm view |

| Scratch Resistance | Pencil test, JIS K 5600 | ≥ HB (uncoated) |

| Color ΔE (UV aging 1 000 h) | CIElab | ≤ 1.0 |

Sampling at T1, T2, and mass-run intervals locks process windows before full ramp-up.

7 Why Source Acrylic Parts through TaiwanMoldMaker.com?

-

Optical-Grade Tooling Culture — Taiwanese shops routinely mold HUD lenses, auto gauge covers, and AR/VR optics for Tier-1 brands.

-

In-House Hard-Coating Lines — Cut weeks off outsourcing cycles and avoid transport scratches.

-

Micro-Venting Expertise — EDM + laser-machined vents down to 0.012 mm eliminate gas traps in thick light pipes.

-

Low WIP, High Repeatability — Industry 4.0 presses with cavity pressure sensors achieve CpK > 1.67—critical for visual zones.

-

Fluent Engineering Support — English-speaking process engineers provide same-day DFM feedback, accelerating approval timetables.

8 Implementation Roadmap

-

Send 3D CAD + Optical Requirements (transmittance, haze, scratch spec).

-

Receive DFM & Moldflow within 48 h (gate location, weld line prediction).

-

Approve Steel & Polish Plan—SPI-A2 or A1 based on lens class.

-

T1 Samples in 3–5 weeks (Al prototype) or 5–7 weeks (S136 steel).

-

Execute Validation—Haze, ΔE, birefringence, dimensional CpK.

-

Scale to Production with documented process window and optional hard-coat line integration.

Ready to Make Your Optics Shine?

TaiwanMoldMaker.com links you to a verified network of Taiwanese acrylic-molding specialists who combine mirror-finish tooling, scientific processing, and in-house hard-coating to deliver parts with glass-like clarity and robust durability.

Contact us today to move your optical or display product from concept to sparkling reality—quickly, reliably, and at globally competitive cost.