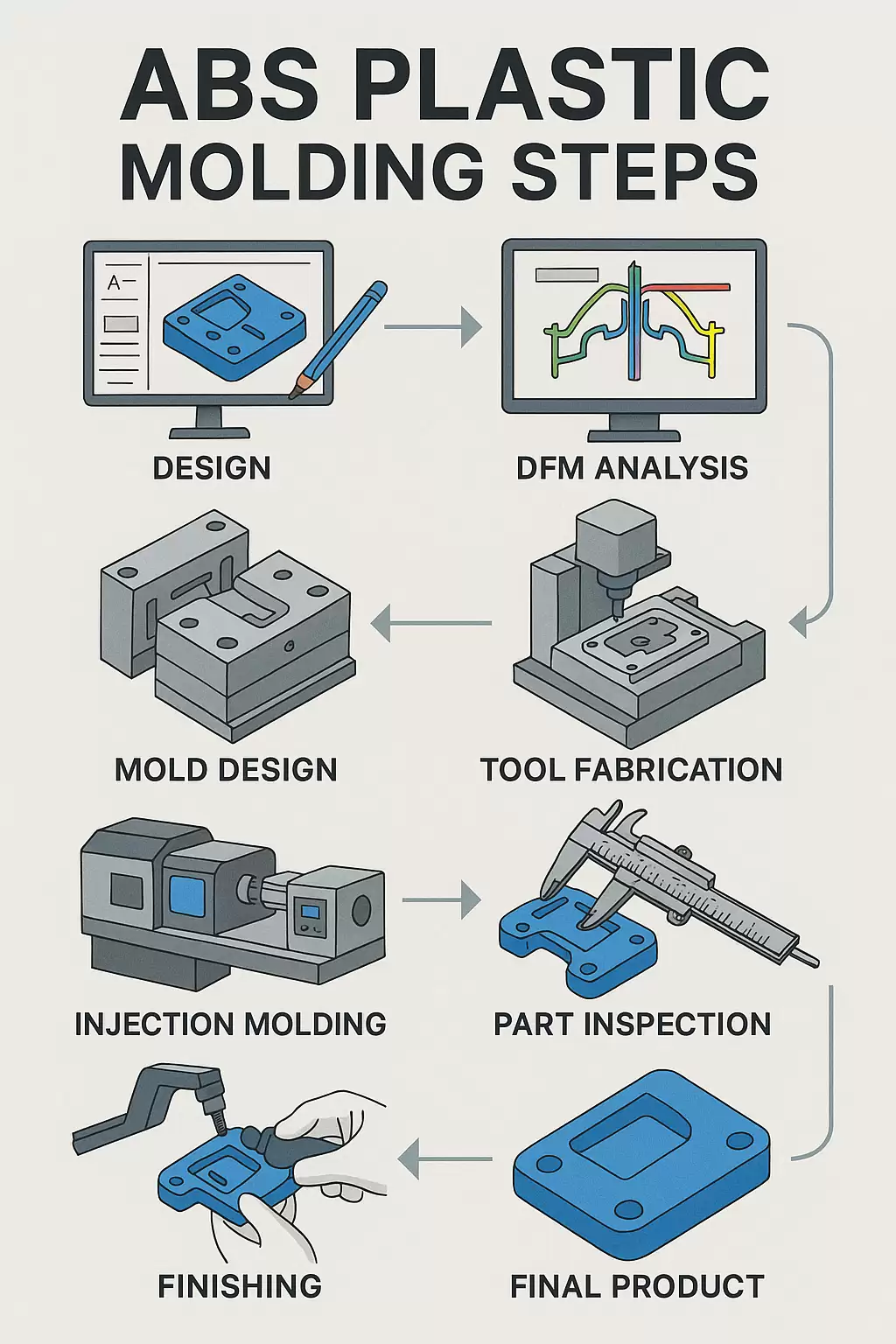

ABS Plastic Molding — Step-by-Step From Design to Finished Product

ABS Plastic Molding — Step-by-Step From Design to Finished Product

Acrylonitrile-Butadiene-Styrene (ABS) pairs everyday toughness with excellent surface aesthetics, making it the go-to polymer for appliance housings, automotive trims, and IoT enclosures. Below is a streamlined, nine-step roadmap that walks you from a blank CAD screen to a shrink-free, production-ready ABS part—so you can launch faster and avoid expensive rework.

1. Concept & Requirements

| Task | What to Capture | Tips |

|---|---|---|

| Function & Loads | Drop-height, thermal range, chemical splash | ABS works -30 °C → 85 °C; avoid prolonged grease contact |

| Regulatory Needs | UL 94 “HB” or “V-0”, RoHS, food-contact | Choose certified grades early to skip retesting |

| Cosmetic Class | Piano-black gloss, texture, or paint-free | Specify SPI finish or VDI texture up front |

2. Part Design & Drafting

-

Wall Thickness: 2.0 – 3.0 mm ± 15 % for warp-free fill.

-

Ribs & Bosses: Thickness ≈ 0.6 × wall; height ≤ 3 × wall.

-

Draft Angles: ≥ 1° on polished faces; 1.5° on textured zones.

-

Snap-Fits: 0.5–0.7 mm under-cut, fillet roots to reduce stress‐whitening.

-

Gating Zone: Hide on non-view surfaces; plan for knit-line away from functional ribs.

3. Design-for-Manufacturability (DFM) & Simulation

| Tool | Outcome | Value |

|---|---|---|

| Moldflow Fill / Pack / Warp | Predict knit lines, sink, air traps | Adjust gate size or add dummy rib before steel cut |

| Cooling Simulation | Optimize baffle or conformal‐cooling layout | Cuts cycle time 10–25 % |

| Draft Check in CAD | Flags negative angles | Avoids costly hand-polish rework |

4. Tool Design Decisions

-

Steel Choice: P20 for mid-volume; S136 or H13 for >1 M shots or glossy Class-A.

-

Runner System: Hot runner with valve gate for thick sections and color-change jobs.

-

Ejection: Balanced pin layout + air-assist for high-gloss faces.

-

Cooling: BeCu inserts or conformal channels under bosses to beat ABS’s moderate thermal conductivity.

5. Tool Fabrication & Validation

| Milestone | Typical Lead Time* | Checks |

|---|---|---|

| Steel Cut & EDM | 3–5 weeks | Hardness, electrode accuracy |

| Bench Fit & Polish | 3–5 days | Surface Ra ≤ 0.05 µm for SPI A-2 |

| T0 / T1 Trials | 1 week | Short-shot study, visual defects |

*Single-cavity P20 tool; multi-cavity adds 2-3 weeks.

6. Machine Setup & Processing ABS

| Parameter | Typical Window | Why |

|---|---|---|

| Resin Drying | 80 °C @ 3–4 h, -40 °C dew-point | Prevents splay & bubbles |

| Melt Temperature | 220–240 °C (grade-specific) | Too low → short shots; too high → yellowing |

| Mold Temperature | 60–80 °C | Higher gloss and dimensional stability |

| Injection Speed | Medium/High; decel at 95 % fill | Packs ribs without jetting |

| V/P Switchover | 90–92 % stroke or cavity-pressure trigger | Avoids burn & sink |

7. Scientific Molding & Quality Control

-

Cavity-Pressure Sensors – Lock fill & pack window; aim CpK ≥ 1.67 on CTQs.

-

Vision Inspection – Detect flow lines, gate blush, surface dirt.

-

SPC Dashboard – Log weight, flash, and gloss every shift.

8. Finishing & Assembly

-

Decoration: UV-cure paint, IMD film, soft-touch TPE over-mold.

-

Laser Marking: Plan flat ≥ 10 × 10 mm area; adjust pigment for contrast.

-

Ultrasonic Welding: Design energy director (≈ 0.5 mm triangular rib) into mating faces.

9. Packaging & Logistics

Heat-sealed bags for piano-black gloss, ESD trays for PCB enclosures, or bulk gaylords for robust under-hood parts. Add QR-code labels for lot traceability and quick recall if needed.

Quick Reference Timeline

| Week | Activity |

|---|---|

| 0–1 | Part design freeze + DFM |

| 2–6 | Tool build & first trial |

| 7 | DOE, process window lock |

| 8 | Cosmetic approval & PPAP |

| 9+ | Mass production + ongoing SPC |

Partner Tip

Using a platform like TaiwanMoldMaker.com gets you 48-hour DFM feedback, Moldflow reports, and side-by-side quotes from ISO-certified ABS molding specialists—so every step above is executed by engineers who handle ABS day-in, day-out.

Key Takeaways

-

Design fundamentals—uniform walls, proper ribs, and adequate draft—eliminate 80 % of ABS molding defects.

-

Simulation + scientific molding provides data-driven control, ensuring repeatable quality.

-

An integrated tooling-through-finishing workflow shortens launch time and slashes TCO.

Ready to turn your ABS concept into a flawless production part? Submit your CAD to TaiwanMoldMaker.com and receive a complete design-to-mass-production roadmap within 48 hours.