Injection Molding - Material,Machine & Mold Temperature Information

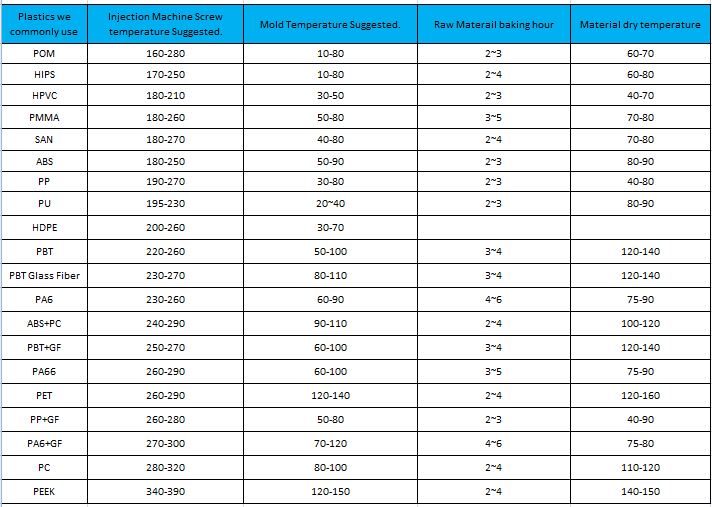

POM, HIPS, HPVC, PMMA, SAN, ABS, PP, PU, HDPE, PBT, PBT Glass Fiber, PA6, ABS+PC, PBT+GF, PA6+GF, PC & PEEK are the plastic materials that we commonly use for making mold and making plastic injection molding production job for customer.

POM, HIPS, HPVC, PMMA, SAN, ABS, PP, PU, HDPE, PBT, PBT Glass Fiber, PA6, ABS+PC, PBT+GF, PA6+GF, PC & PEEK are the plastic materials that we commonly use for making mold and making plastic injection molding production job for customer.

Material, Machine & Mold Temperature information

POM, HIPS, HPVC, PMMA, SAN, ABS, PP, PU, HDPE, PBT, PBT Glass Fiber, PA6, ABS+PC, PBT+GF, PA6+GF, PC & PEEK are the plastic materials that we commonly use for making mold and making plastic injection molding production job for customer.

In this chart, you may easily know all the machine temperature, mold temperature, raw material baking hours and raw material dry temperature information suggested for each differnt plastics molding conidition.

Intertech has good experience in running all these material's mold making and molding production job for long time. Welcome to contact us for your need !

| Plastics we commonly use | Injection Machine Screw temperature Suggested. | Mold Temperature Suggested. | Raw Materail baking hour | Material dry temperature |

| POM | 160-280 | 10-80 | 2~3 | 60-70 |

| HIPS | 170-250 | 10-80 | 2~4 | 60-80 |

| HPVC | 180-210 | 30-50 | 2~3 | 40-70 |

| PMMA | 180-260 | 50-80 | 3~5 | 70-80 |

| SAN | 180-270 | 40-80 | 2~4 | 70-80 |

| ABS | 180-250 | 50-90 | 2~3 | 80-90 |

| PP | 190-270 | 30-80 | 2~3 | 40-80 |

| PU | 195-230 | 20-40 | 2~3 | 80-90 |

| HDPE | 200-260 | 30-70 | ||

| PBT | 220-260 | 50-100 | 3~4 | 120-140 |

| PBT Glass Fiber | 230-270 | 80-110 | 3~4 | 120-140 |

| PA6 | 230-260 | 60-90 | 4~6 | 75-90 |

| ABS+PC | 240-290 | 90-110 | 2~4 | 100-120 |

| PBT+GF | 250-270 | 60-100 | 3~4 | 120-140 |

| PA66 | 260-290 | 60-100 | 3~5 | 75-90 |

| PET | 260-290 | 120-140 | 2~4 | 120-160 |

| PP+GF | 260-280 | 50-80 | 2~3 | 40-90 |

| PA6+GF | 270-300 | 70-120 | 4~6 | 75-80 |

| PC | 280-320 | 80-100 | 2~4 | 110-120 |

| PEEK | 340-390 | 120-150 | 2~4 | 140-150 |

Messenger

Messenger