Related Suppliers

Pressure to reduce costs of tooling calls for better and more up-front engineering. How? By optimizing the use of metals around cavities for example, that directly relates to the amount of machining, heating and cooling, press clamping, logistics, storage and recycling, but mainly, by doing things right the first time.

All of these objectives can be achieved by collaboration and the adoption of simulation technologies based on finite element analysis (FEA), rather than through expensive and time-consuming “trial-and-error” on each company's shop floor, individually.

Structural Mold Analysis

Moldmakers have developed step-by-step guidelines for taking a customer’s idea for a product through part shaping, preliminary plastics requirements, design considerations, layouts, checklists, and working and assembly drawings. However, analysis is often limited to molding problems and solutions—flow balancing besides cavity layout and positioning—through collaboration with the customer, and hot manifold and resin suppliers; the size of tooling has never been truly scrutinized.

In actuality, the structural analysis of a tool or mold, a step to insert after design and prior to drafting for shop manufacturing, includes:

Mold Simulation Example

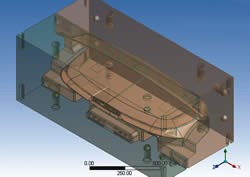

The following example demonstrates the power of simulation in optimizing a generic mold (see Figure 1). A 3-D geometry of the mold was initially obtained from an after-market U.S. plastics molder in the STEP format. This was then read into a FEA pre-processor for preparation of a computer-based (or virtual) model of the mold in operation.

• Simplification of Mold Geometry for FEA

To reduce the size of model and run time on the computer, the mold shown here was reduced to half by virtue of symmetry. Also, computer analysis ought to start with a component at a time, such as the cavity plate in this example. More parts could then be added to an analysis as components get optimized in a virtual environment (prior to ordering steel or machining parts for trials).

• Material Model for Mold FEA

For design purposes in FEA, only two material constants on tooling material are necessary: (1) the elasticity or Young’s modulus which is the slope of the linear reaction to pulling a coupon in unit of stress; and, (2) Poisson’s ratio which relates to the contraction of coupon when stretching. In this example 29 ksi and 0.3 were respectively used off a materials database for modeling.

• Boundary Conditions for Mold FEA

Here, a “mirror” condition was assigned to the plane cutting the mold in two, to account for the missing half by symmetry. Other boundary conditions include compression only at the base half of the mold besides restraints at the slots. Analyzing a full or portion of the mold with the right boundary conditions is to be exactly the same (except that the reduced-sized model would "run" a lot faster on a computer compared to the full-size model).

• Loading of Mold in FEA

“Loading” a mold consists of press tonnage or clamp force and injection pressure in part cavity, as shown in Figure 2. Pressure by the molten plastics could come from a “mold fill” analysis or assumed to be at maximum deliverance of the press, as was the case here. Nonetheless, the analysis being linear elastic, deformations and stresses in the mold will remain proportional to the applied loads.

Results Analysis

While stresses are of prime importance in assessing a mold, when post-processing FEA results, displacements should be looked at first to see if a tooling analysis (static structural in this case) was well set and completed properly.

Color contours of displacements in space showed zero values at the mounting slots and opening of the cavity plate under internal pressure—the highest blue contour corresponds to 0.049 inch in the lateral direction. Transitions from least to maximum displacement contours are gradual and make sense in distribution and magnitude. Color contours of von Mises equivalent stress (combining all tensile and shear components of stresses in all three directions and plans) shown in Figure 3 indicate that most of the mold—except for the bottom of the part cavity and mounting slots—is below the yield stress of structural steel used in this study. Color contours of deformations, strains and/or stresses can interestingly be plotted on non-deformed or deformed geometries, or in fact, on deformed geometries with non-deformed ones still drawn for reference (to help a mold designer or analyst assess FEA outputted results quickly and efficiently).

Mold Optimization

After examining the results of the model-building stage, the geometry of the original half plate of the mold shown was returned to the FEA pre-processor to easily modify its overall size. The goal was to slim down the block of steel required for the job at a toolshop, speeding its delivery, reducing its machining, easing the finding of a press at the customer for molding the parts, while quickening the heating and cooling of plastics and part in production.

Figure 4 contrasts the original mold plate to some proposed optimal design. The shrunkportion of the cavity plate was then brought back to the FEA processor for structural analysis.

Figure 5 shows contours of von Mises equivalent stress on the slimmed down mold plate; red contours raised compared to the bulky design, but not by much. In fact, the design proposed could further be optimized at the bottom of the cavity and mounting slots (in conjunction with the resin material, shape of the molded part, and process conditions) to reduce stresses below yield values. Nonetheless, the shrunk mold plate presented uses close to 59 percent less steel than the original.

Now assuming the cost of P20 or 4140 heat-treated steel to be at $2.50/lb and a density of 0.29 lb/inch3, the cost savings in this example application is $12,317.00 in steel alone on a volume of 4,247 inch3 per quarter core and cavity plates—an amount that could in actuality be crucial in the quoting stages leading to the selection of the mold shop for the project (locally or overseas).

Still, while the initial investment in a numerical or FEA model development of a mold may take several weeks (that would definitely qualify for government R&D dollars), optimizing a mold (such as the example) on a routine basis should not take more than a working week.

Summary

Finite element analysis is available to assess the amount of metal needed around mold cavities for example, and could seamlessly be coupled to existing CAD software at mold shops, while still being able to independently import (in a standalone mode) translated geometries from customers.

Overall, the methodology consists of laboratory testing of tooling materials (epoxy or aluminum for prototyping or hardened steel for production), meshing, application of boundary conditions (to simplify a mold geometry and account for press mounting) and loading (clamping and internal pressure of molten plastics).

Color contours of deformations and stresses in parts of a mold being analyzed get consequently plotted and reviewed then manipulated prior to ordering materials and accessories, and machining components and assembling molds for trials on production equipment. The mold design, material, press requirements and process conditions can this way be optimized quickly and cost-effectively on a computer screen.

The advantages of up-front mold analysis are numerous: they involve shorter delivery times of raw materials and tooling components, cheaper freight, reduced machining time, lower press requirements, faster mold heating and cooling during production, and easier storage, relocation and mold recycling.

In fact, mold shops could very well acquire FEA to develop tooling internally, or strategically team up with a service provider on a case-by-case basis.

References

A comprehensive literature search recently completed by Windsor Industrial Development Laboratory targeted any and all technical papers containing “mold”, “molding” and “FEA” anywhere from 1908 to 2008 using the Compendex Plus and Chemical Abstracts databases at the University of Windsor (http://www.uwindsor.ca), and only five papers out of 283 "hits" registered were judged relevant to reducing the size of mold materials for plastics injection molding.

There are three programs supporting R&D as presented here at firms in Canada (and very similar programs in the USA):

- Materials and Manufacturing Ontario (www.2ontario.com/software/brochures/advancedmanufacturing.pdf)

- Industrial Research Assistance Program of the National Research Council of Canada (http://irap-pari.

nrc-cnrc.gc.ca) - The Scientific Research and Experimental Development of Canada Customs and Revenue Agency, (www1.cata.ca/sred-guidance/partnership.html)