About us

About Us

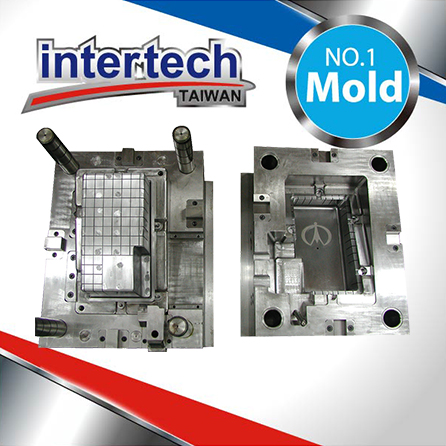

With more than 30 years of experience, Intertech provides an extensive integrated operational ability from design to production of molds 100% made in Taiwan. Additional to our own mold making factory, we also cooperate with our team vendors to form a very strong working force in Taiwan....For the overseas market, we work very closely with local representatives in order to take care of the technical communication and after-sales service to our customers.We also participate in the EUROMOLD & FAKUMA & Formnext exhibitions and meet our customers every year in Europe.

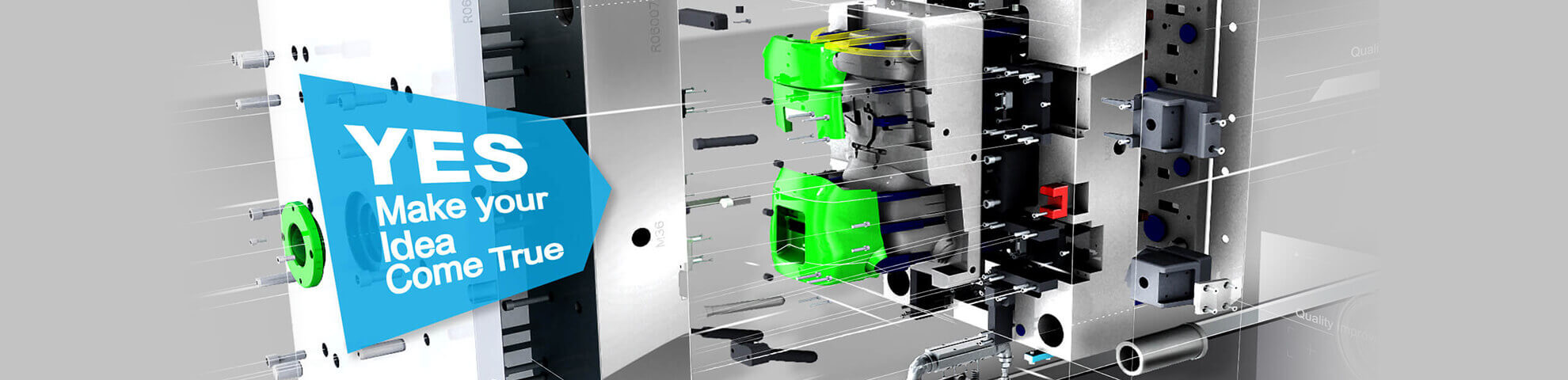

By concentrating on molding and mold "niche markets", we play a very useful molding factory and mold maker role from the Far East, Taiwan, whenever customers want to develop their new projects. We provide services from A to Z to our customers on a very economic cost and effect basis.We manufacture.... custom plastic injection molding parts and molds, custom silicone rubber molding parts and molds, custom stamping die molding parts and molds, custom liquid silicone rubber molding and molds, custom Ls....(Mold Master, MasterFlow, LKM, Incoe systems...etc). We are particularly specialized in dealing with ....undercut molds, unscrewing molds, core pulling structure molds, high gloss polished molds, interchangeable core molds, hot compression molds, 2-component injection molds, and pilot molds for small series production, etc.

The most excellent performance of our molding/mold projects service include.

1. We are excellent in making.... interchangeable cores molding parts....and mold in Taiwan, which is one of the most effective and cost-saving manufacturing process. This kind of mold is especially suitable for those who looks for “more variety but less quantity” solution. By using only one mold, it can generate different kinds of products, which significantly improves the production efficiency.

2. We are especially good at making.... high transparent PC, Acrylic, PMMA, PET.... molding parts and mold , good experience in making high gloss polishing and Mold-Tech texture on parts surface, applied mostly in lighting parts, outdoor LED parts projects.

3.We are famous for.... gas assisted injection molding parts and molds …mostly applied in projects like the thick wall handles, monitors, the frame of TV cabinet etc. Our team is very experienced in handling this kind of mold, which does prevent the shrinkage mark and improve the strength of the parts.

4. Medical silicone and rubber parts and molds making are also our expertise. We manage both “solid” and “liquid” silicone rubber material which meets the standard of ...SR parts molding parts and molds, custom rubber molding parts and molds and hot runner mold.RoHS, FDA and REACH, good in developing those projects like skincare parts, medical earplugs, nipple pacifier, check valve, diving mask....etcrespectively.

5. We are very good in making.... highly-engineered plastic parts project....in Taiwan. With the performance level in Taiwan, we satisfy our world customers with.... the best value of mold making workmanship: customer design service; prototyping; mold making; manufacturing process control; reverse engineering; customer molding & assembly, etc.....We keep many key customers giving us repeated orders from Finland, Sweden, Denmark, the Netherlands, Germany, the U.K, the U.S.A, South Africa, Syria, Cyprus, the Philippines, etc.